Microneedle female die, microneedle female die, preparation process of microneedle female die, microneedle patch and preparation process of microneedle patch

A technology of microneedle and master mold, applied in the field of microneedle, can solve the problems of complex process, low production efficiency of negative mold, long time consumption, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Embodiment 1 microneedle master mold

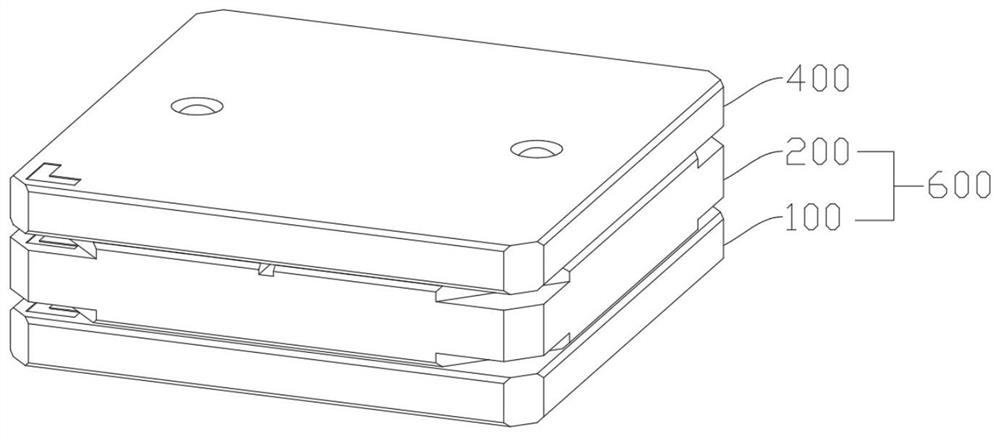

[0086] combine Figure 1-Figure 9 As shown, a microneedle master mold includes a mold core 100, a mold frame 200, a defoaming film 300 and a mold cover 400, wherein the mold core 100 and the mold frame 200 are combined to form the bottom mold 600 of the microneedle master mold, and the bottom mold The mold 600 is provided with a PDMS forming tank 500, and the defoaming film 300 is attached to the upper surface of the PDMS forming tank 500 for degassing operation; The defoaming film 300 is tightly pressed onto the PDMS forming groove 500, and the mold cover 400 is used for setting the female mold to ensure that the PDMS mixture will not be deformed during the forming process. The mold core 100 , the mold frame 200 and the mold cover 400 can be made of metal or 3D printing material, and the material of the defoaming film 300 can be made of PET material.

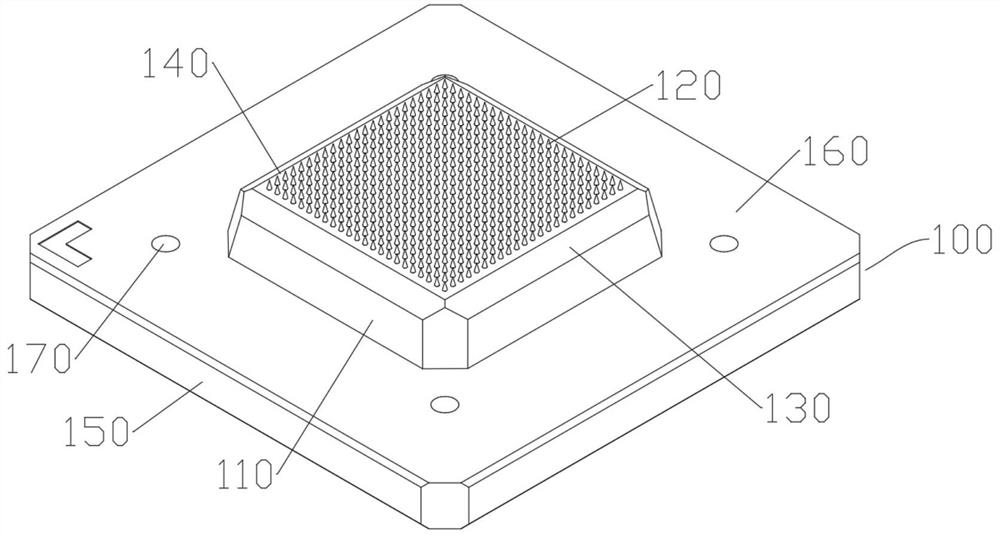

[0087] Specifically, see figure 2 As shown, the mold core 100 includes a fi...

Embodiment 2

[0103] Embodiment 2 microneedle negative mold and its preparation process

[0104] The embodiment of the present invention also provides a microneedle female mold. The microneedle female mold is a PDMS female mold with an inverted microneedle array inside. The microneedle female mold is prepared by using the microneedle female mold in Example 1. , and its preparation process is as follows:

[0105] Step 1. Weigh 10g of curing agent and 100g of uncrosslinked PDMS solution, keep mechanical stirring at 500rpm for 3min, place in a vacuum defoamer to remove air bubbles, and obtain PDMS mixed solution;

[0106] Step 2: Put the mold frame 200 on the mold core 100, and use bolts to fix the mold frame 200 to the bolt holes 170 and 250 of the mold core 100, and after fixing, a microneedle platform accommodation cavity 270 and the microneedle platform 110 form a A PDMS forming groove 500 is provided, the bottom of the PDMS forming groove 500 is the free end surface of the microneedle pl...

Embodiment 3

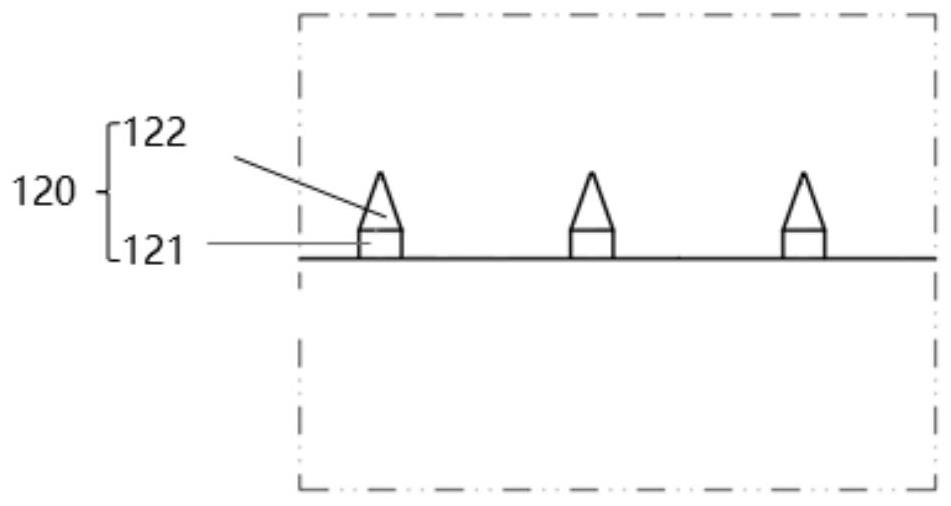

[0113] This embodiment 3 provides a microneedle master mold, including a bottom mold 600, a mold cover and a defoaming film 300. The difference from the embodiment 1 is that the bottom mold 600 described in this embodiment 3 has an integrated structure, see attached Figure 13 As shown, the integrally formed bottom mold 600 is provided with a PDMS forming groove 500, and the PDMS forming groove 500 in the bottom mold in the third embodiment is circular. The PDMS forming groove is recessed from the end surface of the bottom mold 600, and a microneedle protrusion 120 is arranged in the middle, and the shape of the microneedle protrusion 120 includes but not limited to bullet shape, conical shape, pyramid shape, okra shape and pyramid shape. The defoaming film 300 covers the PDMS molding tank 500 , and the mold cover (not shown) is pressed on the bottom mold 600 and the defoaming film 300 .

[0114] Further, the upper surface of the bottom mold 600 can also be provided with an o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com