Shell encapsulated microcapsule phase change material as well as preparation method and application thereof

A phase change material, shell encapsulation technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve problems such as inability to fully meet the actual needs of construction projects, unfavorable performance such as resistance to ion penetration, complex preparation processes, etc. The effect of small impact on strength development, low cost and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

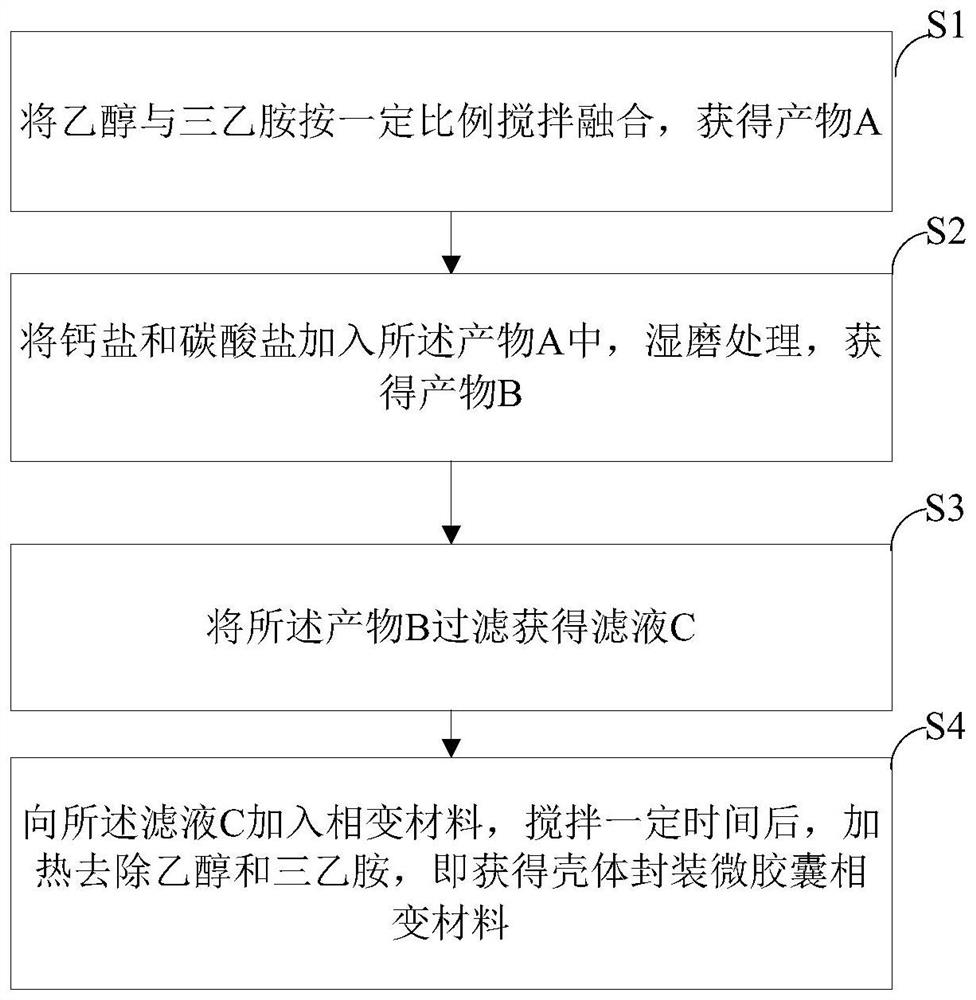

Method used

Image

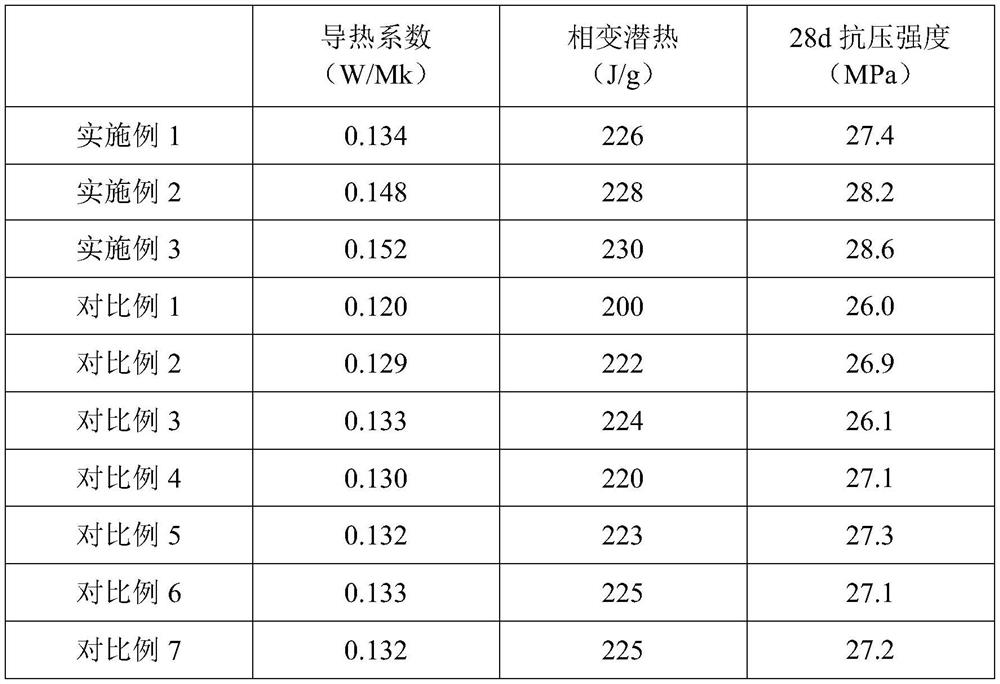

Examples

Embodiment 1

[0037] Add 1000g of ethanol solution into 500g of triethylamine, put it into a magnetic stirrer, stir and fuse to obtain product A, the stirring speed of the magnetic stirrer is 500r / min, and the stirring time is 15min. 10g of sodium carbonate and 10g of calcium chloride are added into the product A, and put into a wet mill for grinding treatment, and the wet mill adopts nitrogen to reach a constant temperature of 15 DEG C; Among them, the rotating speed of wet mill is 800r / min, the wet milling time is 2h, and the nitrogen rate is 18Nm. 3 / h, the wet grinding medium is zirconia. After grinding, product B is obtained, and the product B is put into a separatory funnel for filtering operation to separate solid from liquid. Add the filtered liquid into a three-necked flask, then add 5g microcrystalline paraffin, start magnetic stirring at a stirring speed of 300r / min, and the stirring time is 30min. Heat it in a water bath heating mode, raise the temperature to 40℃ at a heating rate o...

Embodiment 2

[0039] Add 1000g of ethanol solution into 750g of triethylamine, put it into a magnetic stirrer, stir and fuse to obtain product A, the stirring speed of the magnetic stirrer is 500r / min, and the stirring time is 15min. 10g of sodium carbonate and 10g of calcium nitrate are added into the product A, and put into a wet mill for grinding treatment, and the wet mill adopts nitrogen to reach a constant temperature of 15 DEG C; Among them, the rotating speed of wet mill is 800r / min, the wet milling time is 2h, and the nitrogen rate is 19Nm. 3 / h, the wet grinding medium is zirconia. After grinding, product B is obtained, and the product B is put into a separatory funnel for filtering operation to separate solid from liquid. Add the filtered liquid into a three-necked flask, then add 7.5g microcrystalline paraffin, start magnetic stirring at a stirring speed of 300r / min for 30min, heat it in a water bath heating mode, heat it to 40℃ at a heating rate of 5℃ / min, and keep it for 2 hours, ...

Embodiment 3

[0041] Add 1000g of ethanol solution into 1000g of triethylamine, put it into a magnetic stirrer, stir and fuse to obtain product A, the stirring speed of the magnetic stirrer is 500r / min, and the stirring time is 15min. 10g of sodium carbonate and 10g of calcium chloride are added into the product A, and put into a wet mill for grinding treatment, and the wet mill adopts nitrogen to reach a constant temperature of 15 DEG C; Among them, the speed of wet mill is 800r / min, the wet milling time is 2h, and the nitrogen rate is 20Nm. 3 / h, the wet grinding medium is zirconia. After grinding, product B is obtained, and the product B is put into a separatory funnel for filtering operation to separate solid from liquid. Adding the filtered liquid into a three-necked flask, then adding 10g microcrystalline paraffin, starting magnetic stirring at a stirring speed of 300r / min for 30min, heating in a water bath, heating to 40℃ at a heating rate of 5℃ / min, and keeping for 2 hours, and heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com