Phosphorite decarbonization calcining device and method

A calcination device and decarbonization technology, applied in the direction of furnace, furnace type, charge control, etc., can solve the problems of incomplete combustion, metal residue smoke and dust pollution environment, etc., achieve small loss on ignition, save energy consumption, and high calcination efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

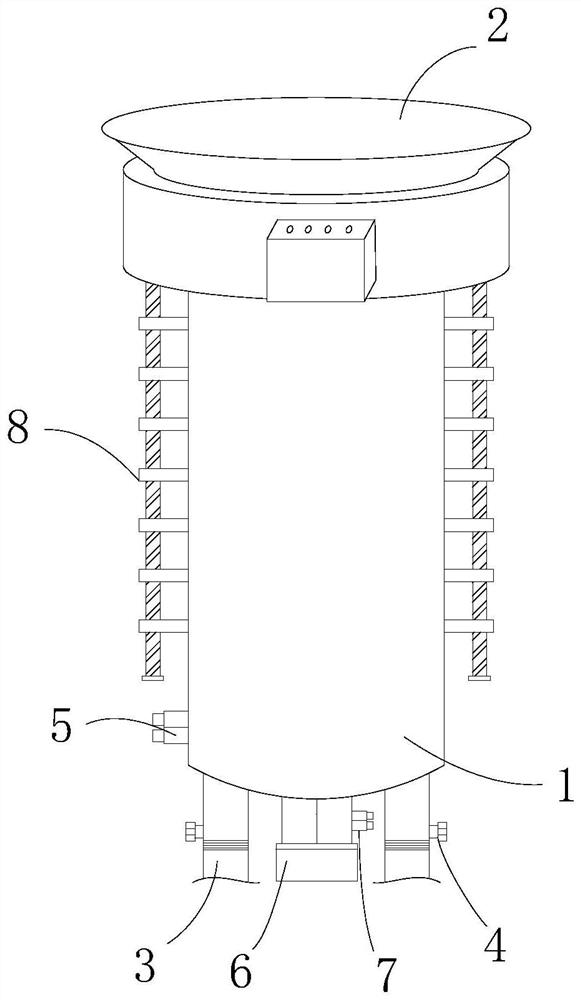

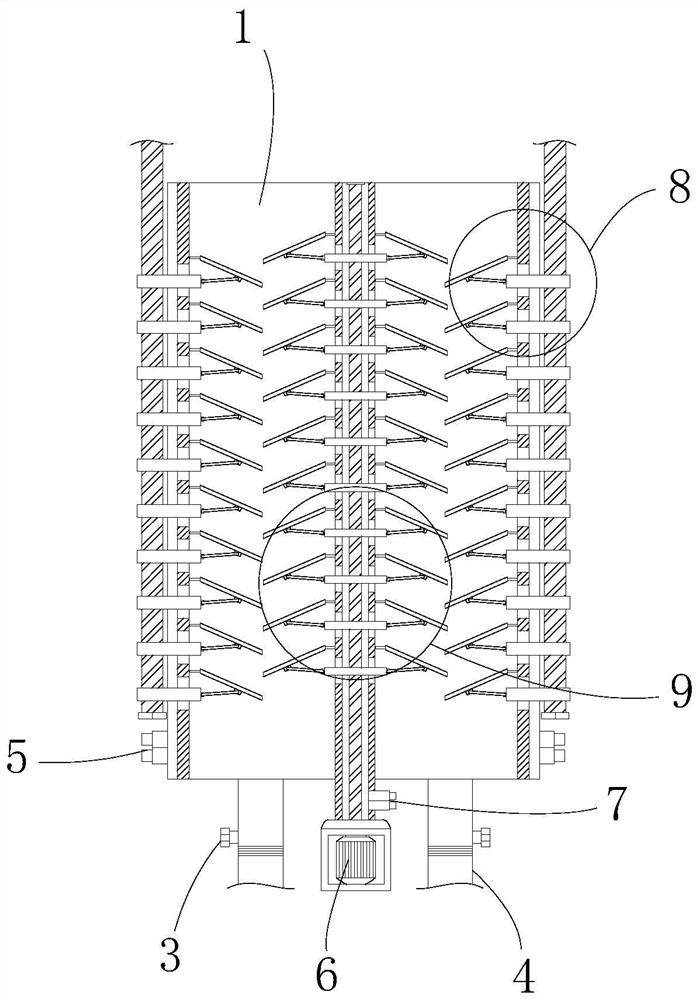

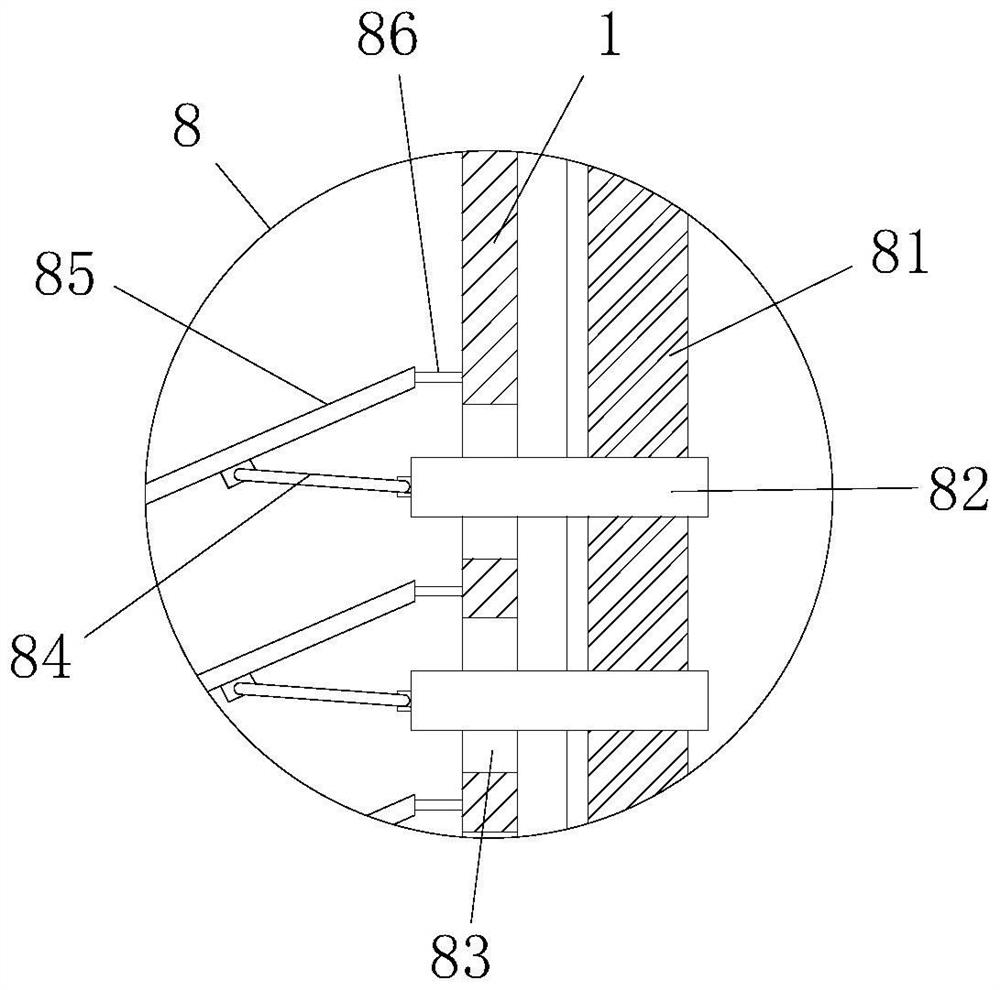

[0033] like Figure 1-5 As shown, a phosphate rock decarburization and calcination device includes a calciner body 1, a feeding port 2, and a discharge channel 3. The calciner body 1 includes an outer ring combustion mechanism and an inner ring combustion mechanism, and the outer ring combustion mechanism and the inner ring combustion mechanism. A first material guide mechanism 8 and a second material guide mechanism 9 with adjustable inclination are symmetrically arranged between the mechanisms;

[0034] The present invention can realize the process from heating to soaking in the calcining furnace by means of the outer ring combustion mechanism and the inner ring combustion mechanism in which the cycle alternates the inner and outer calcination methods. The feeding mechanism 9 makes the phosphate rock stay and calcined on the first feeding mechanism 8 and the second feeding mechanism 9, which increases the calcining surface of the phosphate rock, reduces the accumulation of o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com