Method for determining and verifying length of tuyere of blast furnace

A method and technology for determining the tuyere, which is applied in the field of determining and verifying the length of the tuyere of a blast furnace, and can solve the problems of affecting the edge airflow, lack of scientific basis and technical solutions, and no scientific and reasonable method to determine the length of the tuyere.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

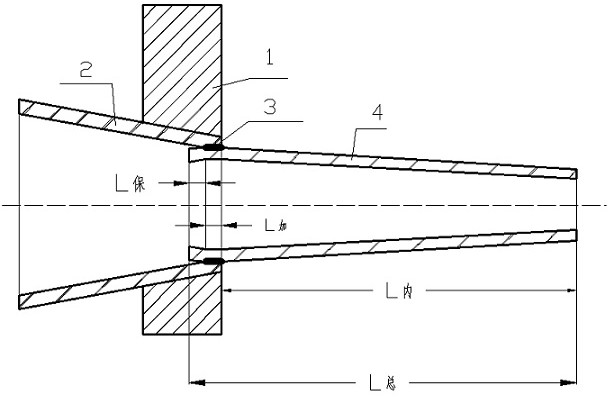

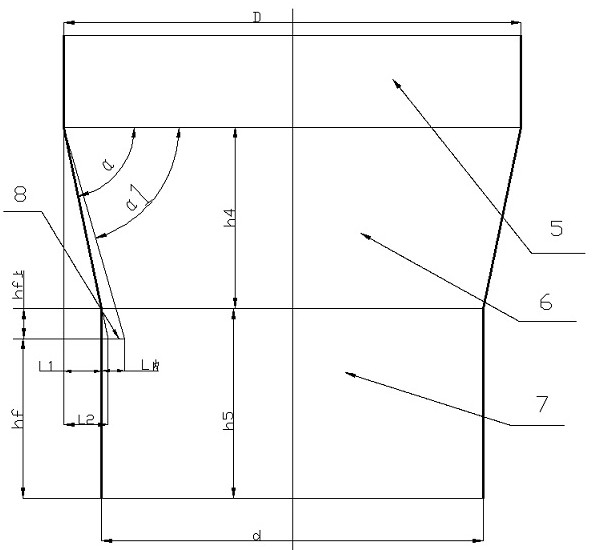

[0077] Such as figure 1 , 2 As shown, the effective volume is 2000m 3 Blast furnace, known furnace type parameters, furnace waist diameter, D, 11750mm. Bosh height, h2, 3050mm. Hearth diameter, d, 10500mm. Hearth height, h1, 4200mm. Tuyer height, hf, 3600m. The length of the processed surface at the rear end of the tuyere, L plus, 100mm, the protected length of the processed surface at the rear end of the tuyere, L Bao, 0mm.

[0078] The height of the upper part of the tuyere hf 上 = h1-hf=4200-3600=600mm

[0079] According to the reasonable range of the effective bosh angle: 73°~75°, the reasonable range of the length of the tuyere extending into the hearth can be obtained, that is, the reasonable range of the length of the tuyere processed finished product.

[0080] a) The upper limit of the reasonable range of the effective bosh angle is 75°, and the lower limit of the length of the tuyere extending into the furnace hearth. At this time, the length L of the tuyere e...

Embodiment 2

[0088] Effective volume 3600m 3 Blast furnace, known furnace type parameters, furnace waist diameter, D, 14200mm. Bosh height, h2, 3600mm. Hearth diameter, d, 12690mm. Hearth height, h1, 4900mm. Tuyer height, hf, 4300m. The length of the processed surface at the rear end of the tuyere is 100mm, and the protection length of the processed surface at the rear end of the tuyere is 100mm.

[0089] The height of the upper part of the tuyere hf = h1- hf=4900-4300=600mm

[0090] According to the reasonable range of the effective bosh angle: 73°~75°, the reasonable range of the length of the tuyere extending into the hearth can be obtained, that is, the reasonable range of the length of the tuyere processed finished product.

[0091] a) The upper limit of the reasonable range of the effective bosh angle is 75°, and the lower limit of the length of the tuyere extending into the furnace hearth. At this time, the length L of the tuyere extending into the furnace hearth=TAN((90°-α1) / ...

Embodiment 3

[0099] Furnace type parameters of a certain blast furnace, furnace waist diameter, D, 11800mm. Bosh height, h2, 3300mm. Hearth diameter, d, 10400mm. Hearth height, h1, 4500mm. Tuyer height, hf, 3600m.

[0100] The height of the upper part of the tuyere hf 上 = h1-hf=4500-3600=900mm

[0101] The length of the processed surface at the rear end of the tuyere, L plus, 100mm, the protected length of the processed surface at the rear end of the tuyere, L Bao, 0mm. The finished length of tuyere processing (L total), 450mm.

[0102] The length L of the tuyere extending into the hearth = L total - L plus - L protection = 450-100-0 = 350mm

[0103] Calculate the effective belly angle of the blast furnace according to the length of the tuyere extending into the hearth:

[0104] Effective belly angle of blast furnace α1=90°-ATAN(((D-d) / 2+L 内 ) / (h1- hf+h2)) / PI()*180=90°-ATAN(((11800-10400) / 2+350) / (4500-3600+3300)) / PI()*180=76 °.

[0105] The effective bosh angle is 76°, which exc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com