Preparation method of whipped yoghurt

A technology of yogurt and bacterial strains, which is applied in the direction of milk preparations, dairy products, and other dairy products, can solve health problems and other problems, and achieve the effect of delicate taste, low fat content, and strong milk flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

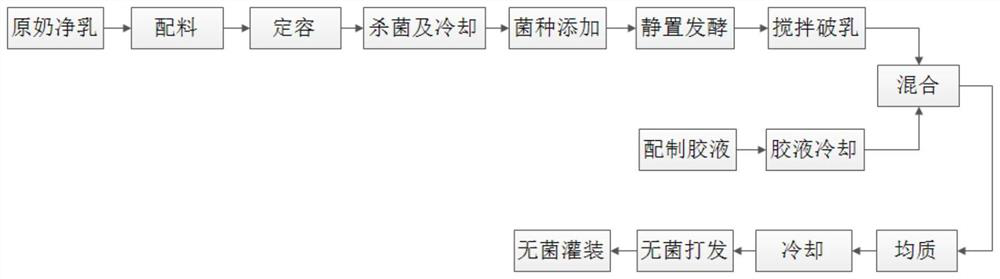

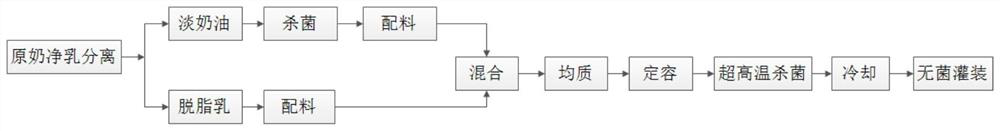

[0039] One embodiment of the present invention provides a method for preparing whipped yogurt, comprising the following steps:

[0040] (1) Preparation of yogurt: using raw milk with a fat content of 3.0-4.0% by weight, carrying out batching, constant volume, sterilization and cooling, adding strains, and standing fermentation to obtain yogurt;

[0041] (2) On-line glue mixing: Stir the yogurt obtained in step (1) to break the emulsion; dissolve the edible gelatin in water to obtain the glue; Mix, then homogenize, cool to 3-6°C to obtain feed liquid;

[0042] (3) Stirring with aseptic aeration: Stir the cooled feed liquid obtained in step (2), and fill in sterile air during the stirring process to obtain a whipped yoghurt dairy product mixed with gas, that is, whipped.

[0043] The preparation method of the whipped yogurt of the present invention uses raw material milk with low fat content to ferment to make yogurt, and performs aseptic aeration and stirring after the demulsi...

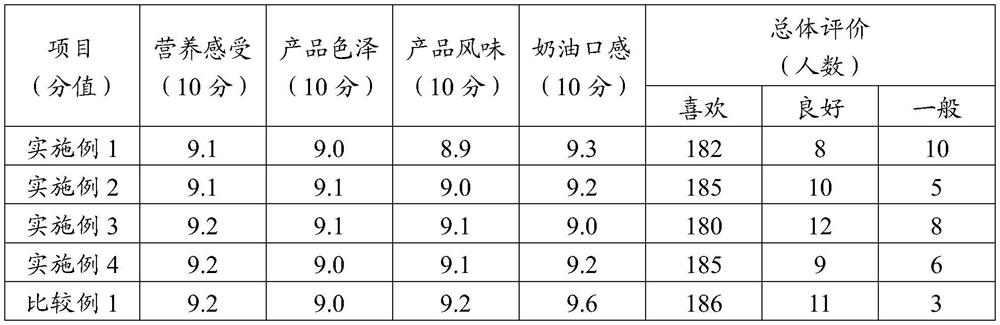

Embodiment 1

[0066] (1) Composition of raw materials: 888.96kg of milk with a fat content of 4.0% by weight, 100kg of white granulated sugar, 5kg of hydroxypropyl distarch phosphate, 1kg of diacetyl tartrate mono- and diglycerides, 2kg of pectin, 3kg of agar, and 3kg of fermentation strains The dosage is 0.04kg, 3kg of edible gelatin, and 55kg of purified water.

[0067] (2) Using the above raw materials, prepare the whipped yoghurt dairy product according to the following steps.

[0068] Raw milk cleaning: The raw milk is subjected to centrifugal cleaning treatment through a separator to obtain centrifugally purified milk.

[0069] Ingredients: Take part of the raw milk after centrifugation and purification, heat up to 58°C, add food additives to stir the material, make it dispersed and dissolved, pour it into the tank to be filled to prepare for constant volume.

[0070] Constant volume: Pour the remaining centrifugally purified raw milk into the tank to be filled with chemical raw mate...

Embodiment 2

[0083] (1) Composition of raw materials: 900.07kg of milk with a fat content of 3.9% by weight, 90kg of white granulated sugar, 4.5kg of hydroxypropyl distarch phosphate, 0.8kg of diacetyl tartrate mono- and diglycerides, 1.8kg of pectin, 2.8kg of agar, fermented Strain 0.03kg, edible gelatin 5kg, purified water 70kg.

[0084] (2) Using the above raw materials, prepare the whipped yoghurt dairy product according to the following steps.

[0085] Raw milk cleaning: The raw milk is subjected to centrifugal cleaning treatment through a separator to obtain centrifugally purified milk.

[0086] Ingredients: Take part of the raw milk after centrifugation and purification, heat up to 55°C, add food additives to stir the material, make it dispersed and dissolved, pour it into the tank to be filled to prepare for constant volume.

[0087] Constant volume: Pour the remaining centrifugally purified raw milk into the tank to be filled with chemical raw material milk for constant volume, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com