Injection system and method for reducing dioxin and mercury in incineration flue gas

A technology of incineration flue gas and injection system, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of filter bag blockage, filter bag corrosion, mercury metal, etc., to reduce dioxin and mercury, and reduce noise. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

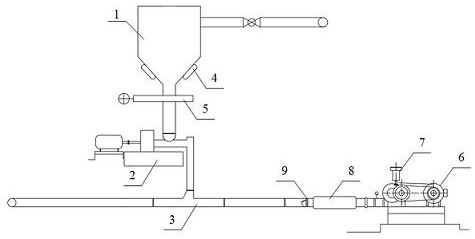

[0035] The present invention provides a method for reducing dioxin and mercury in the incineration flue gas. First, the powdered activated carbon is transported to the storage bin 1 through the feeding device, and then the activated carbon is quantitatively transported to the mixer 3 through the metering feeder 2 When the high-pressure air produced by the blower 6 at the throat of the mixer 3 passes through the throat of the mixer 3 at a high speed, a negative pressure is generated to adsorb the activated carbon, and the adsorbed activated carbon and the high-pressure air are sprayed together through the air blowing device 4 The flue after the deacidification tower fully mixes the activated carbon powder and the flue gas, and the activated carbon removes dioxin and mercury in the flue gas by adsorption. The injection amount of the activated carbon is 150mg / Nm 3 , the adsorption time is 20min, and the adsorption temperature is 100°C.

Embodiment 2

[0037] The present invention provides a method for reducing dioxin and mercury in the incineration flue gas. First, the powdered activated carbon is transported to the storage bin 1 through the feeding device, and then the activated carbon is quantitatively transported to the mixer 3 through the metering feeder 2 When the high-pressure air produced by the blower 6 at the throat of the mixer 3 passes through the throat of the mixer 3 at a high speed, a negative pressure is generated to adsorb the activated carbon, and the adsorbed activated carbon and the high-pressure air are sprayed together through the air blowing device 4 The flue after the deacidification tower fully mixes the activated carbon powder and the flue gas, and the activated carbon removes dioxin and mercury in the flue gas by adsorption. The injection amount of the activated carbon is 80mg / Nm 3 , the adsorption time is 15min, and the adsorption temperature is 120°C.

Embodiment 3

[0039] The present invention provides a method for reducing dioxin and mercury in the incineration flue gas. First, the powdered activated carbon is transported to the storage bin 1 through the feeding device, and then the activated carbon is quantitatively transported to the mixer 3 through the metering feeder 2 When the high-pressure air produced by the blower 6 at the throat of the mixer 3 passes through the throat of the mixer 3 at a high speed, a negative pressure is generated to adsorb the activated carbon, and the adsorbed activated carbon and the high-pressure air are sprayed together through the air blowing device 4 The flue after the deacidification tower fully mixes the activated carbon powder and the flue gas, and the activated carbon removes dioxin and mercury in the flue gas by adsorption. The injection amount of the activated carbon is 120mg / Nm 3 , the adsorption time is 10min, and the adsorption temperature is 90°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com