Single-layer-multi-stage full-automatic vibration screening system

A vibratory screening and fully automatic technology, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc., can solve the problems of unsatisfactory screening requirements, small screening position range, and uneven screening, etc. The effect of moving and using, less dust emission, and high screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further elaborated below by means of the accompanying drawings and examples.

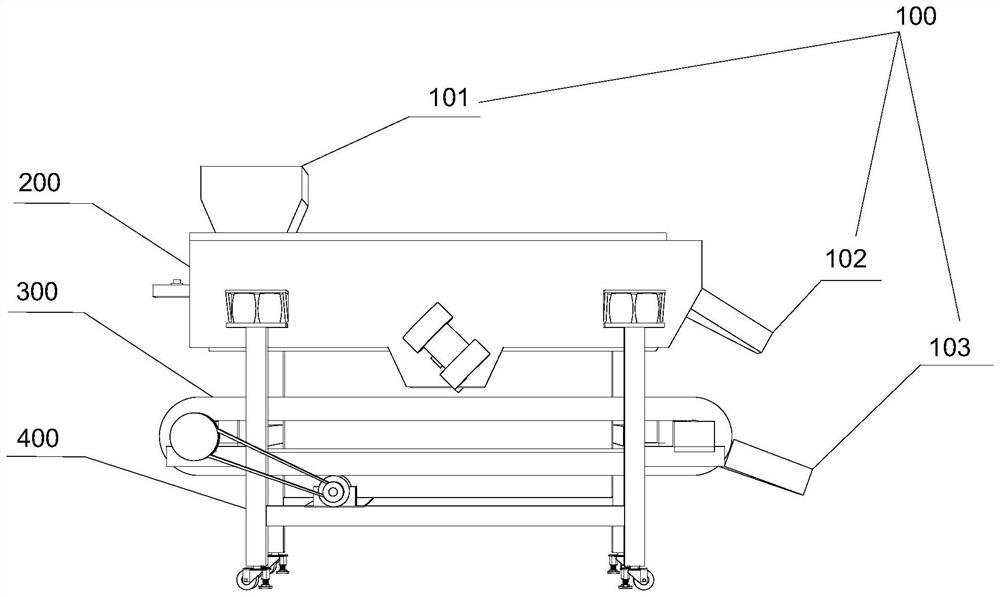

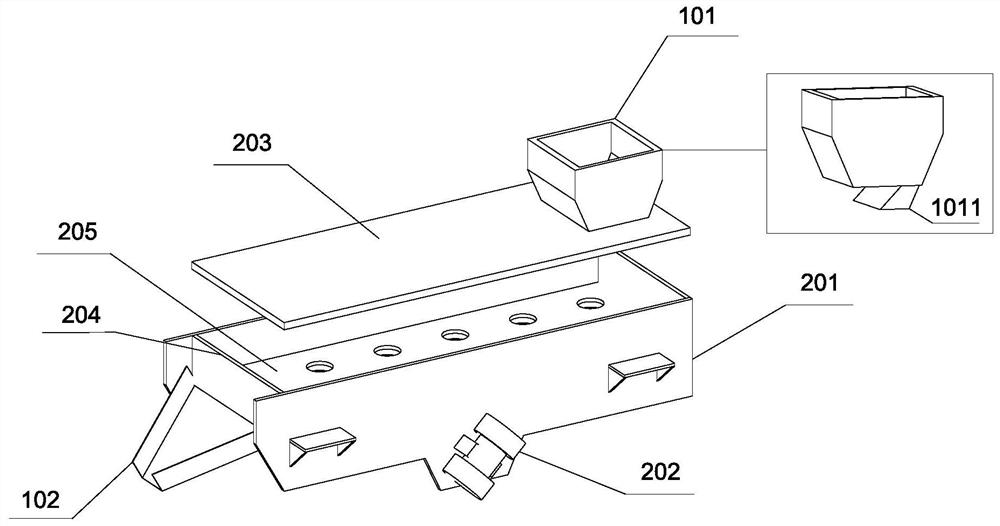

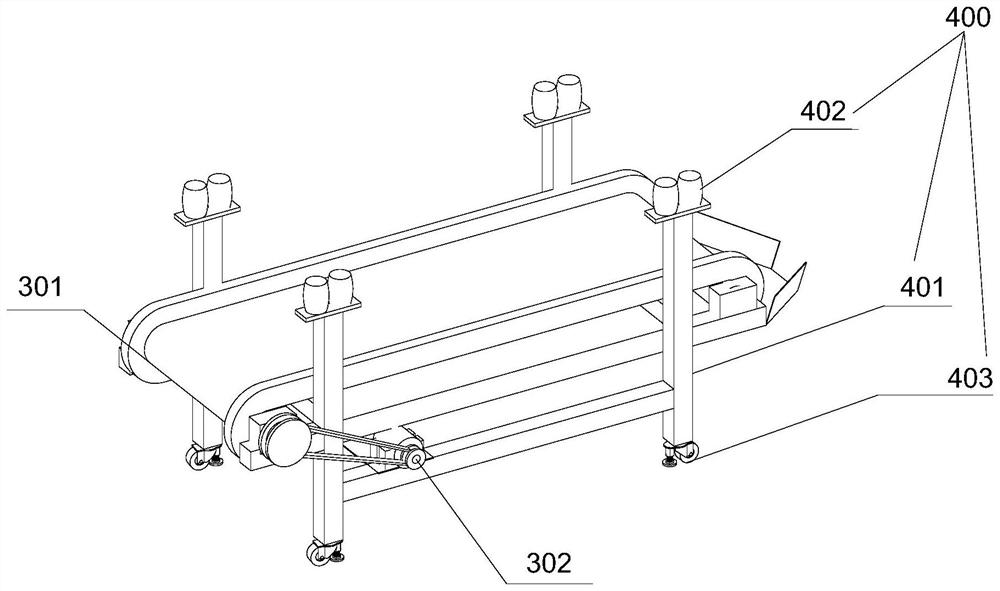

[0029] like Figure 1-3 Shown: a single-layer-multi-stage fully automatic vibrating screening system, mainly including 4 parts in total of feeding and discharging system 100, sealed screen box 200, conveying system 300, and supporting frame 400 (such as figure 1 As shown), through the coordinated operation of the system, the precise and efficient screening of stone materials is completed.

[0030] According to the above scheme, the feeding and discharging system 100 includes a material inlet 101 , a material outlet 1 102 , and a material outlet 2 103 , and the material inlet 101 and the detachable box cover 203 are integrally structured.

[0031] The feed port 101 adopts a trumpet structure, and there is a buffer slope 1011 inside to reduce the impact on the single-layer-multi-stage screen surface 205 when gravel is fed, and to protect the screen surface.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com