Metal plate surface grinding and cutting integrated device

A metal sheet, integrated technology, applied in shearing devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of easy splashing of cooling water, low processing efficiency, pollution of the working environment, etc., to achieve good cooling effect and avoid pollution. , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

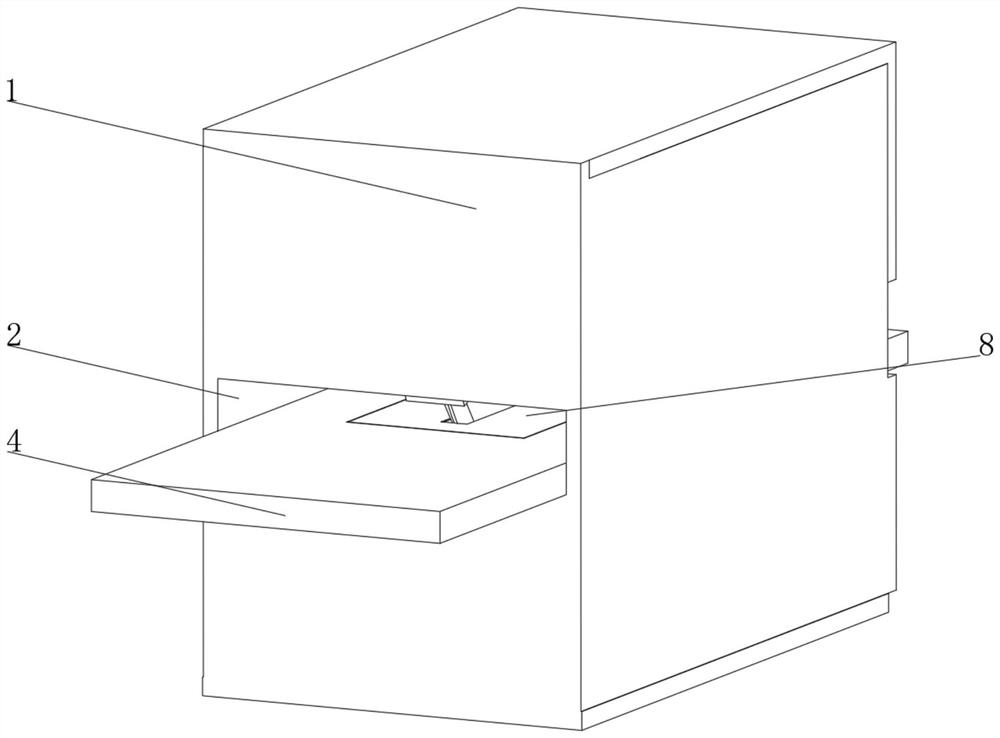

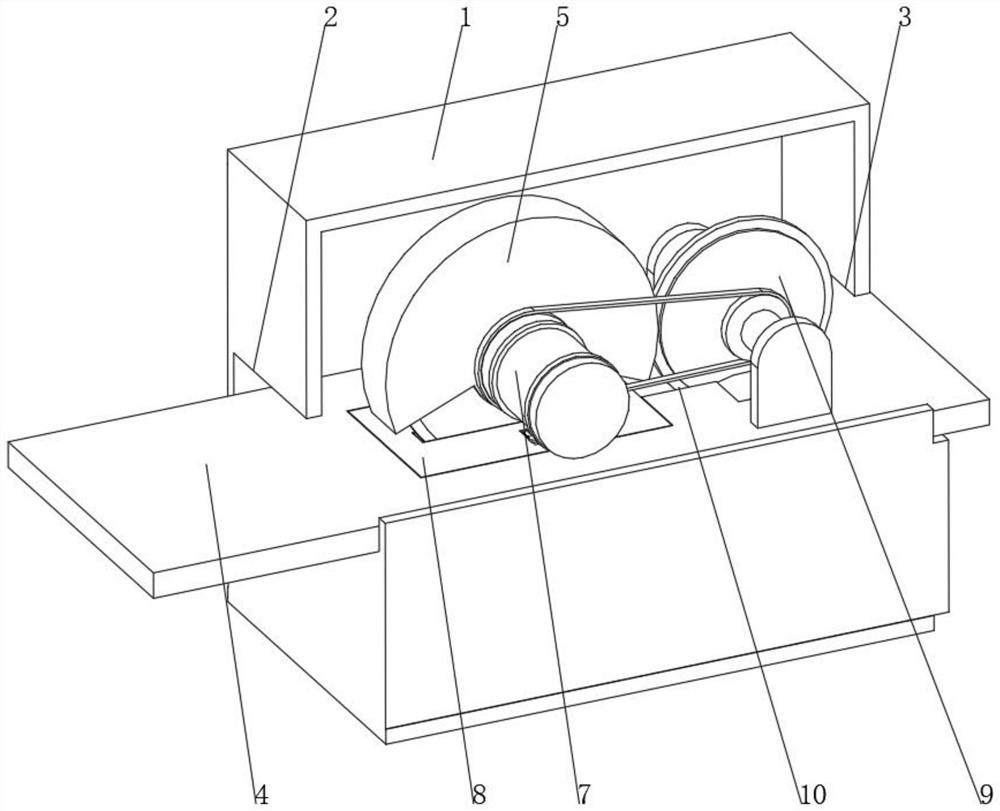

[0040] see Figure 1-Figure 3 , the present invention provides a technical solution: a metal plate surface grinding and cutting integrated device, specifically comprising:

[0041] The device shell 1, the two sides of the device shell 1 are respectively provided with a material inlet 2 and a material outlet 3, and the inside of the device shell 1 is fixedly connected with a workbench 4, and the workbench 4 is provided with a cutting port 10;

[0042] A cutting knife 5, the side of the cutting knife 5 runs through and is fixedly connected with a cutting shaft 6, one end of the cutting shaft 6 is fixedly connected with a drive motor 7, and the cutting shaft 6 is away from the drive motor 7 and is connected to the inner wall of the device shell 1 for rotation;

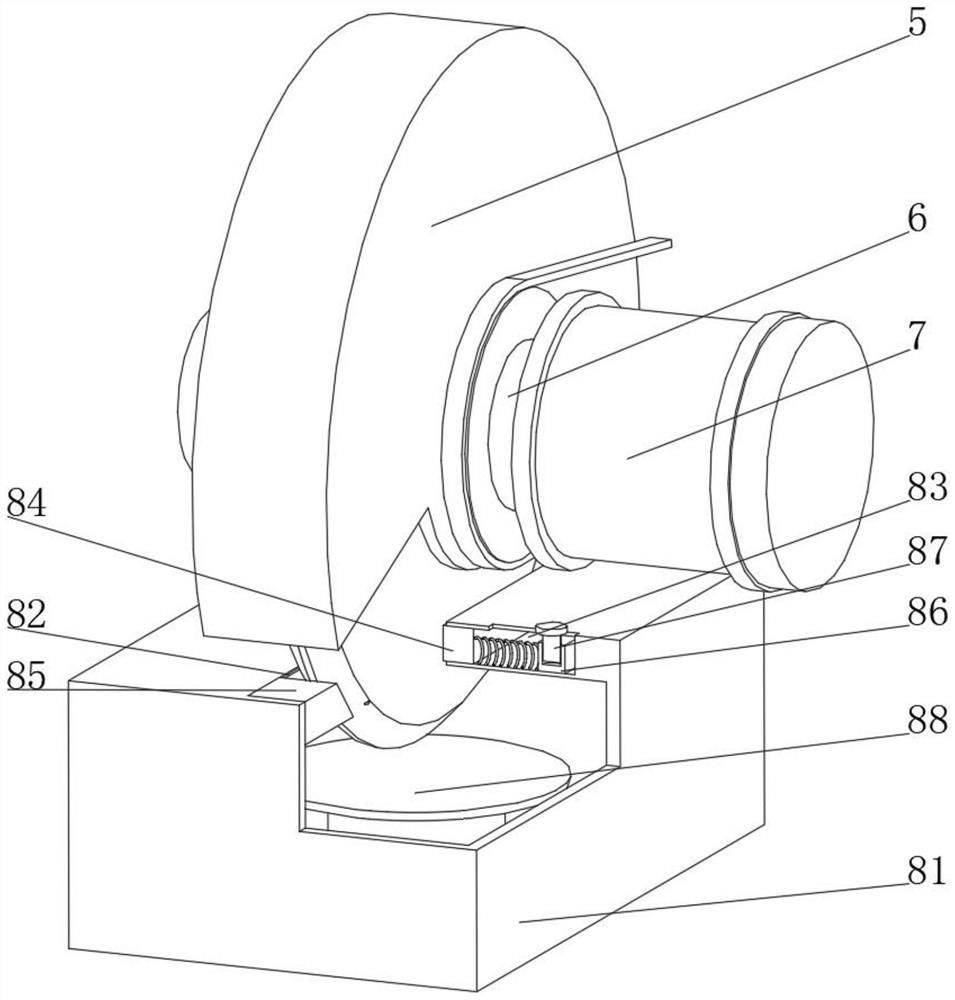

[0043] Cooling device 8, this cooling device 8 is arranged on the part below the cutting knife 5 on the workbench 4, the bottom of the cutting knife 5 runs through the cooling device 8 and extends to the inside of the coo...

Embodiment 2

[0052] see Figure 1-Figure 4 On the basis of Embodiment 1, the present invention provides a technical solution: the control device 88 includes a control sleeve 881, the top of the inner wall of the control sleeve 881 penetrates and is slidably connected with a sliding sleeve 882, and the top of the sliding sleeve 882 is fixedly connected with a floating Plate 883, a limit spring 884 is arranged between the bottom of the sliding sleeve 882 and the top of the inner wall of the control sleeve 881, the bottom of the inner wall of the control sleeve 881 is fixedly connected with a control switch 885, and the inner wall of the sliding sleeve 882 is slidably connected with an extrusion piston 886. The bottom of the pressure piston 886 extends to the outside of the sliding sleeve 882 and faces the control switch 885. The control sleeve 881 is arranged inside the cooling box 81 and is fixedly connected to the bottom of the inner wall of the cooling box 81. The control switch 885 is ele...

Embodiment 3

[0054] see Figure 1-Figure 5 On the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the grinding device 9 includes an upper bracket 91, the inner wall of the upper bracket 91 is connected with an upper grinding disc 92 through an upper rotating shaft 96, and the outer side of the upper grinding disc 92 is covered An outer ring gear 93 is set and fixedly connected, the bottom of the outer ring gear 93 is meshed with a lower gear 94, both sides of the lower gear 94 are fixedly connected with a lower grinding disc 95 through a lower rotating shaft 97, and the bottom of the upper rotating shaft 96 is connected elastically through a rotating sleeve. Expansion plate 98, the bottom of elastic expansion plate 98 is rotatably connected with rollers, the side of elastic expansion plate 98 is fixedly connected with upper support 91, the bottom of lower rotating shaft 97 is rotatably connected with lower support 99, lower support 99 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com