High-physical-property glass fiber reinforced artificial leather and preparation method thereof

A technology of artificial leather and high physical properties, which is applied in the direction of chemical instruments and methods, textiles and papermaking, glass/slag layered products, etc. It can solve the problems of long time, chemical odor escape, chemical odor, etc., and achieve good rigidity, The effect of low density and high modulus of elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

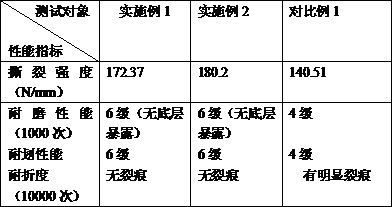

Examples

Embodiment 1

[0018] A kind of preparation method of the artificial leather reinforced with high physical property glass fiber, comprises the following steps:

[0019] Step 1: Take 50 parts by mass of waterborne polyurethane resin, 0.5 part of antioxidant, and 0.3 part of antifungal agent, and mix them uniformly at 45°C to obtain a resin layer slurry;

[0020] Step 2: Evenly coat the resin layer slurry obtained in Step 1 on the surface of the non-woven base fabric by 1 mm;

[0021] Step 3: Lay the 0.5mm thick glass fiber mesh cloth woven with glass fiber evenly on the surface of the resin layer in step 2, and dry at 70°C;

[0022] Step 4: Mix 70-80 parts of TPO resin, 5-15 parts of filler short glass fiber, 1 part of antioxidant, and 1 part of ultraviolet light absorber, and evenly coat 0.8mm on the surface of the glass fiber mesh cloth in step 3. Dry at 70°C to obtain finished artificial leather.

Embodiment 2

[0024] A kind of preparation method of the artificial leather reinforced with high physical property glass fiber, comprises the following steps:

[0025] Step 1: Take 80 parts by mass of waterborne polyurethane resin, 1 part of antioxidant, and 0.8 part of antifungal agent, and mix them uniformly at 45°C to obtain a resin layer slurry;

[0026] Step 2: Evenly coat the resin layer slurry obtained in Step 1 on the surface of the non-woven base fabric with a thickness of 0.8mm;

[0027] Step 3: Lay the 0.5mm thick glass fiber mesh cloth woven with glass fiber evenly on the surface of the resin layer in step 2, and dry at 70°C;

[0028] Step 4: Mix 80 parts of TPO resin, 15 parts of filler short glass fiber, 1 part of antioxidant, and 1 part of ultraviolet light absorber, evenly coat 1mm on the surface of the glass fiber mesh cloth in step 3, and dry at 70°C to obtain Finished leatherette.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com