Railway train pantograph device capable of automatically adjusting pantograph-catenary contact pressure

A technology of contact pressure and rail trains, applied in the direction of electric vehicles, collectors, vehicle components, etc., can solve the problems of inability to adjust operation faults in time, manual measurement is large, and not real-time, and achieve real-time automatic adjustment of contact pressure and safety High, avoid abnormal wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

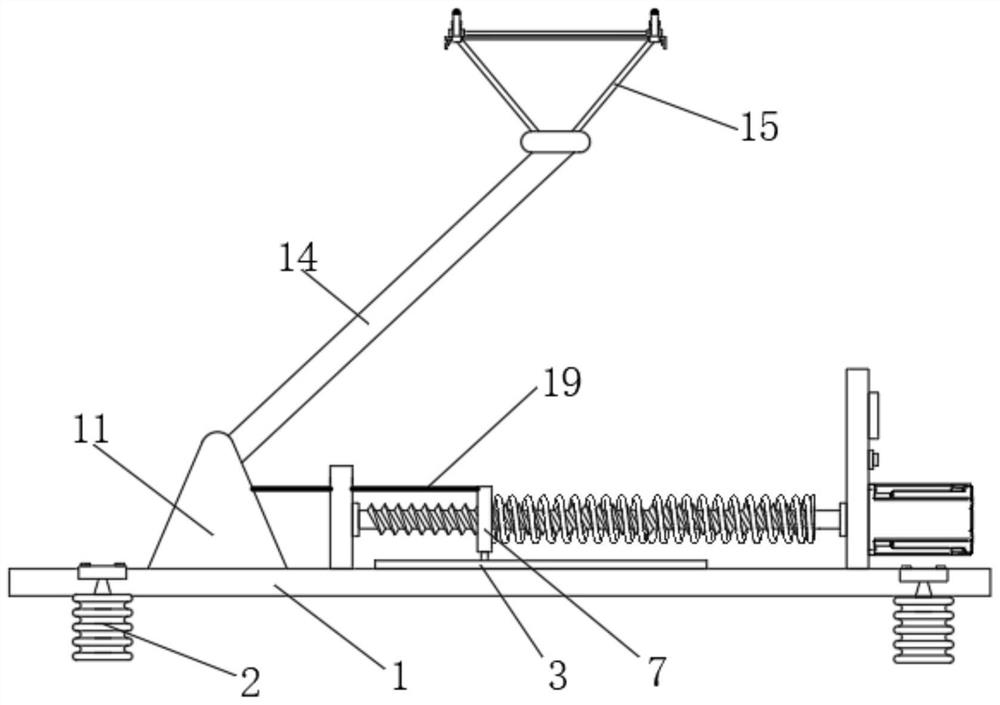

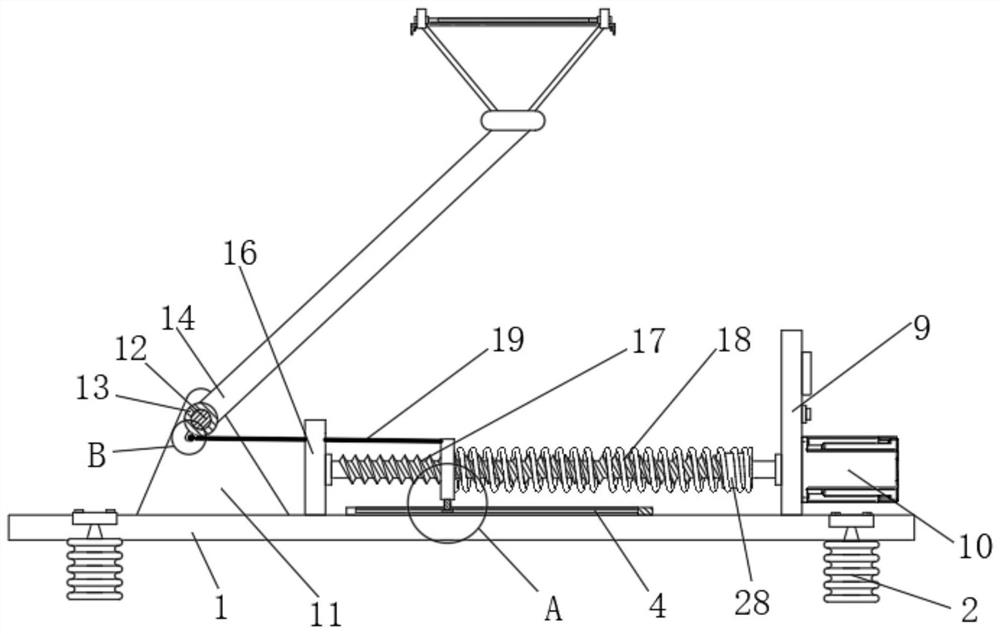

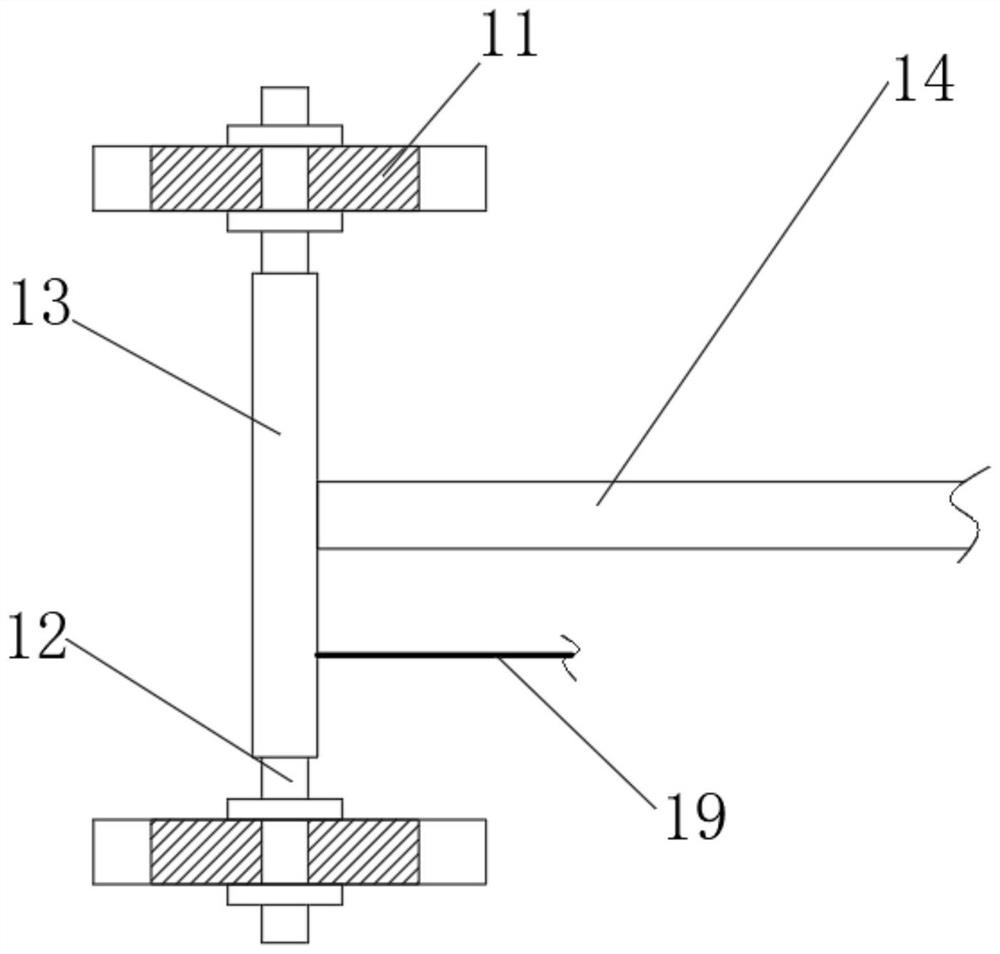

[0031] see Figure 1-9 , the present invention provides a technical solution: a rail train pantograph device that can automatically adjust pantograph-catenary contact pressure, including a base 1, and a driving mechanism, a sliding mechanism and a lifting mechanism are arranged above the base 1;

[0032] The driving mechanism includes a motor board 9, a servo motor 10 and a screw rod 17. The motor board 9 is fixedly connected to the top of the base 1, the servo motor 10 is fixedly connected to one side of the motor board 9, and one end of the output shaft of the servo motor 10 moves through the motor. On the surface of the plate 9, one end of the output shaft of the servo motor 10 is fixedly connected to one end of the screw rod 17 through a coupling, and the servo motor 10 is a DC drive motor with a reduction gear that can rotate positively and negatively, and has a power-off self-locking function , the rotation of the servo motor 10 drives the screw rod 17 to rotate, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com