Derrick type elevator

A technology of elevators and derricks, applied in the direction of elevators, elevators, buildings, etc. in buildings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

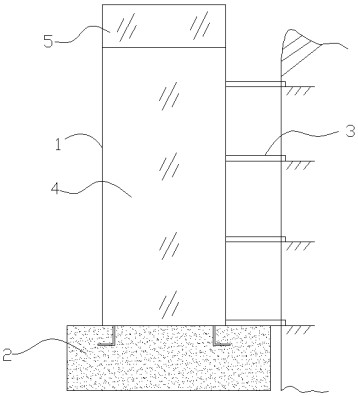

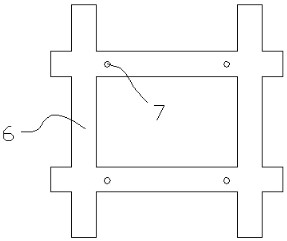

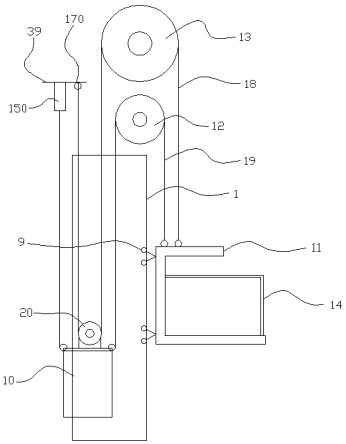

[0038] combine Figure 1 to Figure 7 The derrick type elevator shown includes a hoistway frame 1 arranged on one side of the floor wall, the upper end of the hoistway frame 1 is provided with a machine room 5, and a part of the decorative plate 4 is arranged on the outside of the hoistway frame 1. The decorative plate 4. Glass plates can be used. The lower end of the hoistway frame 1 is installed on the concrete foundation 2. The concrete foundation 2 is a well-shaped structure 6. A car module is installed in the hoistway frame 1. The car module includes a A guide rail assembly on one side of the hoistway frame 1, a counterweight 10 is slidably installed in the guide rail assembly, a car assembly is slidably installed on one side of the guide rail assembly, and a power output motor 12 is installed in the machine room 5. The top of the power output motor 12 is provided with a speed-limited stop device 13, the output shaft on the power output motor 12 is equipped with a power gear...

Embodiment 2

[0049] Such as Figure 8 As shown, the difference between the second embodiment and the first embodiment is that the second synchronous belt connection buffer seat 15 is respectively installed on the sliding frame 29, and the second synchronous belt connection buffer seat 15 and the synchronous belt 19 The ends are connected, and the side of the second synchronous belt connected to the buffer seat 15 is provided with a second wire rope fixing port 17, and the second wire rope fixing port 17 is connected to the end of the steel wire rope 18; The seat 15 and the second wire rope fixing port 17 directly connect the synchronous belt 19 and the wire rope 18 with the balance weight 10, and form a 1:1 suspension ratio with the car body, so that the structure is more simplified and compact, and the transmission efficiency is higher.

[0050] The structure of the second synchronous belt connection buffer seat 15 is the same as that of the first synchronous belt connection buffer seat 1...

Embodiment 3

[0052] Such as Figure 9 with Figure 10 As shown, the difference between the third embodiment and the first embodiment is that the side of the well-shaped frame 6 close to the floor wall is flat when viewed from the side, so that the distance between the hoistway frame 1 and the floor wall is Smaller, there is no need to install the corridor attachment 3 between the hoistway frame 1 and the floor wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com