Method for preparing glycated albumin calibrator and quality control product

A technology for glycosylated albumin and quality control products, applied in the field of biomedicine, can solve the problems of cumbersome processing steps, difficulty in taking into account cost and process convenience, and many instruments and equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

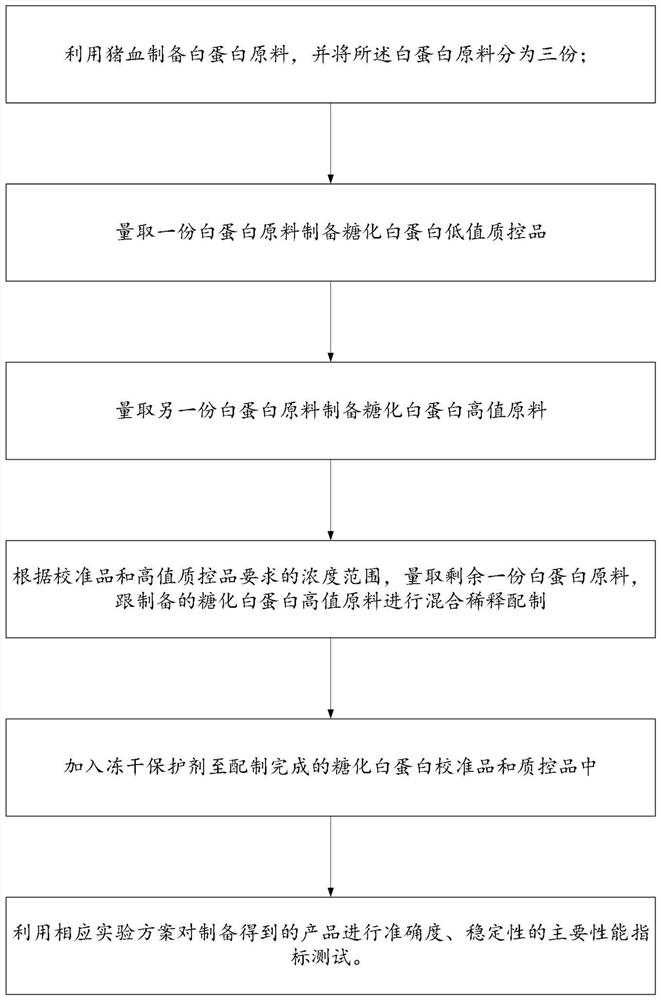

Method used

Image

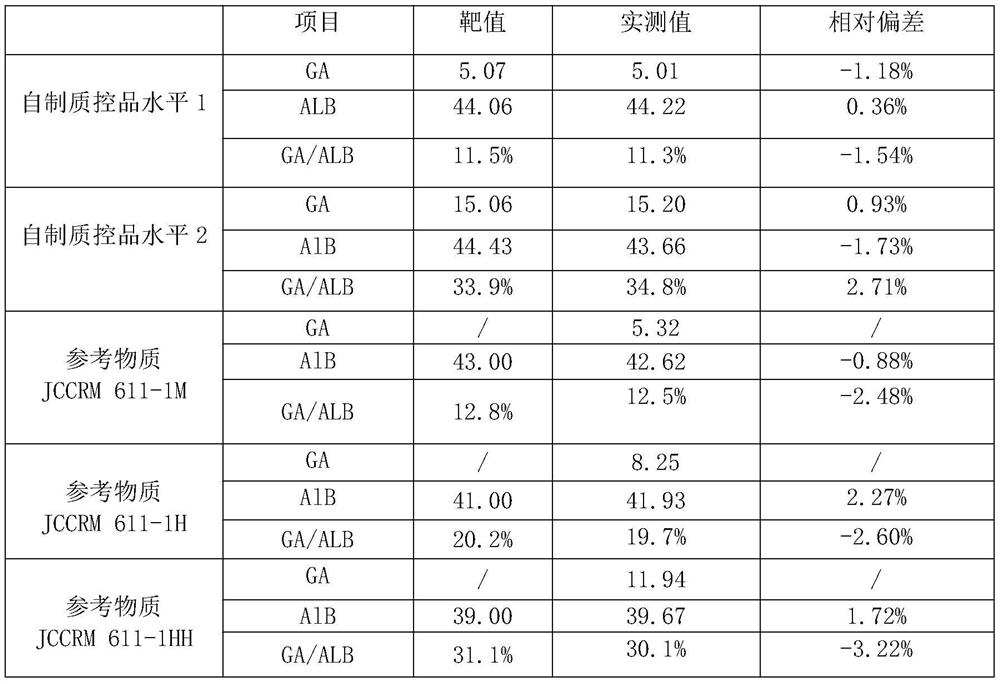

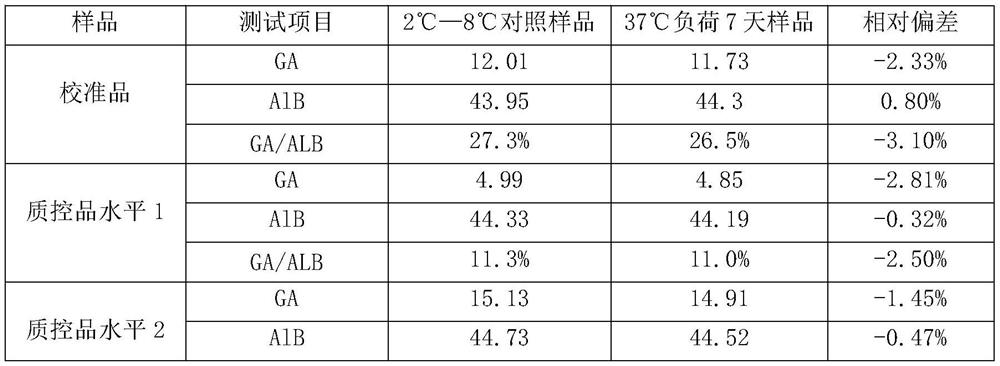

Examples

Embodiment 1

[0061] Specifically, embodiment 1, a method for preparing glycated albumin calibrator and quality control product, comprises the following steps:

[0062] S1: Porcine serum processing and porcine serum albumin raw material preparation

[0063] S1.1: Take pig serum, use a high-speed centrifuge at 6000rpm-8000rpm, centrifuge for 20min-30min, discard the precipitate, and keep the supernatant;

[0064] S1.2: Take the centrifuged pig serum raw material, measure the volume accurately, slowly add solid ammonium sulfate, stir while adding, so that its saturation is 50%, after the addition, continue stirring for 15min-30min, until the ammonium sulfate is completely dissolved ;

[0065] S1.3: Use a high-speed centrifuge to centrifuge at 6000rpm-8000rpm for 20min-30min, discard the precipitate, and keep the supernatant;

[0066] S1.4: Use GE polysulfone membrane tangential flow ultrafiltration column to ultrafilter the supernatant after dialysis and centrifugation, control the concentr...

Embodiment 2

[0089] Specifically, embodiment 2, a method for preparing glycated albumin calibrator and quality control product, comprises the following steps:

[0090] S1: Porcine serum processing and porcine serum albumin raw material preparation

[0091] S1.1: Take pig serum, use a high-speed centrifuge at 7000rpm-9000rpm, centrifuge for 20min-30min, discard the precipitate, and keep the supernatant;

[0092] S1.2: Take the centrifuged pig serum raw material, measure the volume accurately, slowly add solid ammonium sulfate, and stir while adding, so that its saturation is 60%. After adding, continue to stir for 15-30 minutes until the ammonium sulfate is completely dissolved ;

[0093] S1.3: Use a high-speed centrifuge to centrifuge at 7000rpm-9000rpm for 20min-30min, discard the precipitate, and keep the supernatant;

[0094] S1.4: Use Fresenius hollow fiber ultrafiltration column to ultrafilter the supernatant after dialysis and centrifugation, control the concentration of albumin af...

Embodiment 3

[0117] Specifically, Embodiment 3, a method for preparing glycated albumin calibrator and quality control product, comprising the following steps:

[0118] S1: Porcine Serum Processing and Porcine Blood Albumin Raw Material Preparation

[0119] S1.1: Take pig serum, centrifuge at 8000rpm~10000rpm with a high-speed centrifuge for 20min~30min, discard the precipitate, and keep the supernatant;

[0120] S1.2: Take the raw porcine serum after centrifugation, measure the volume accurately, slowly add solid ammonium sulfate, and stir while adding, so that its saturation is 60%, after adding, continue stirring for 15min-30min, until the ammonium sulfate is completely dissolved ;

[0121] S1.3: Centrifuge at 8000rpm~10000rpm for 20min~30min with a high-speed centrifuge, discard the precipitate, and keep the supernatant;

[0122] S1.4: Use Fresenius hollow fiber ultrafiltration column to ultrafiltration and dialysis the supernatant after centrifugation, and control the albumin concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com