Modularized tunnel excavation simulation test device and assembling method thereof

A technology of tunnel excavation and simulation test, which is applied in the direction of assembly machine, soil material test, material inspection product, etc. The effect of investment in reducing impact and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

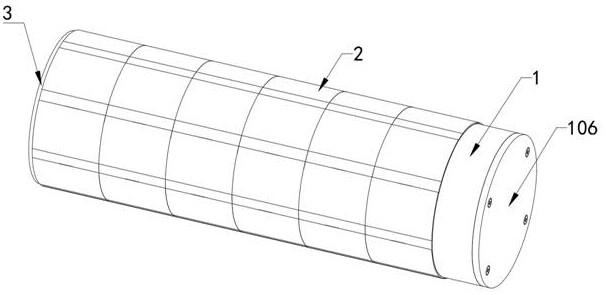

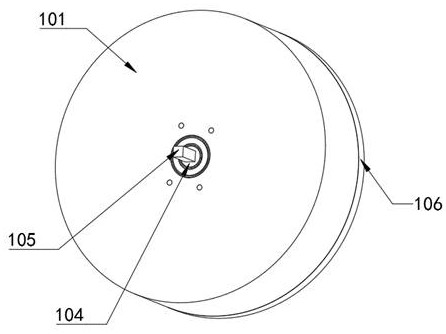

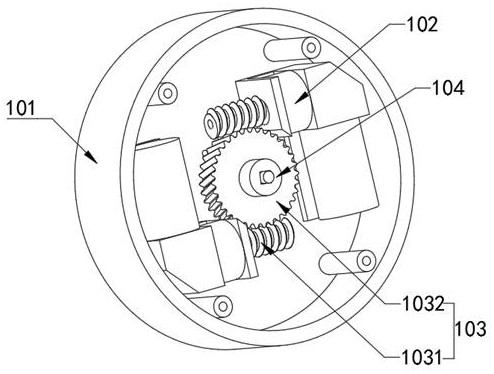

[0045] Such as Figure 1-Figure 11 As shown, a modular tunnel excavation simulation test device includes a driving part 1, the output end of the driving part 1 is connected with a tunnel model, and the driving part 1 is used to drive the tunnel model to change its own use diameter. The tunnel model consists of at least one set of The excavation module 2 is composed, and the end of the tunnel model away from the drive part 1 is provided with a closure assembly 3, and the drive part 1 is connected with a fixing rod, which is used to fix the end of the tunnel model on the drive part 1.

[0046] Specifically, in the present invention, one or more sets of excavation modules 2 are spliced into a tunnel model according to the simulation requirements, and the tunnel model and the driving part 1 are fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com