Variable frequency motor use temperature measuring method and device, computer and storage medium

A technology for temperature measurement and variable frequency motors, applied in devices, temperature measurement methods for variable frequency motors, computers and storage media, can solve problems such as long test time, increased heat generation, inter-turn breakdown, etc., and achieve short and accurate test time High performance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

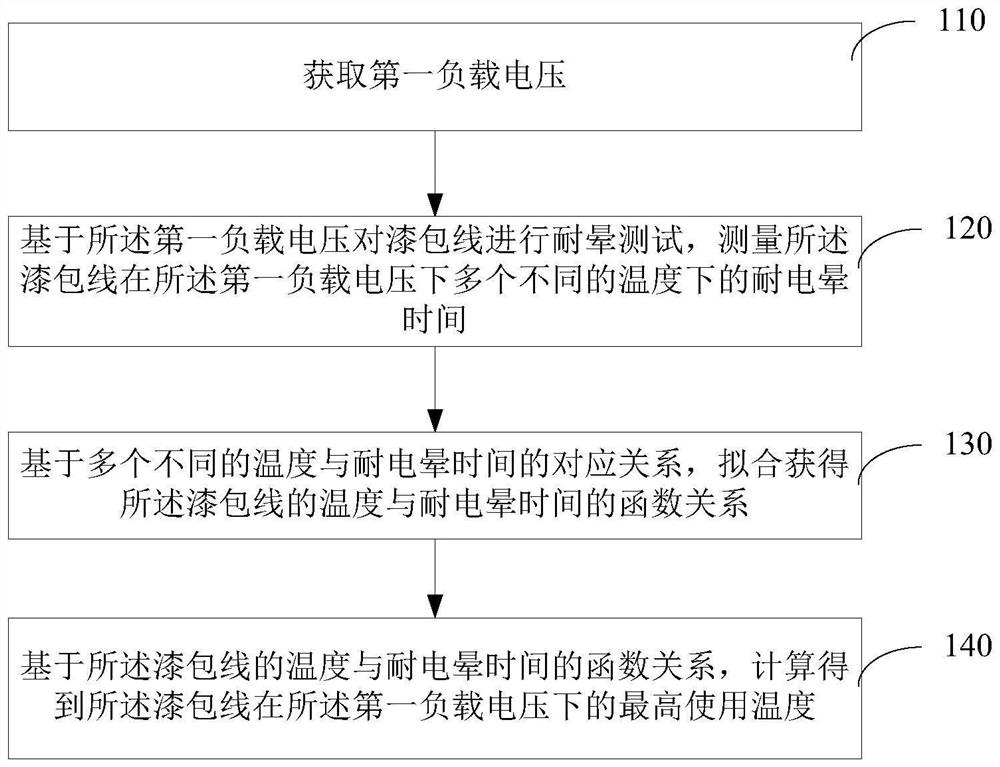

[0052] In the example, such as figure 1 As shown, a method for measuring the temperature of a variable frequency motor is provided, which includes:

[0053] Step 110, acquiring a first load voltage.

[0054] In this embodiment, the first load voltage is a test voltage. In one round of testing, a voltage value is selected as the first load voltage for testing. Under the first load voltage, tests are performed multiple times. Subsequently, in the next round of testing, another voltage value is selected as the second load voltage and tested again.

[0055] Step 120: Perform a corona resistance test on the enameled wire based on the first load voltage, and measure the corona resistance time of the enameled wire at a plurality of different temperatures under the first load voltage.

[0056] Specifically, the enameled wire is a corona-resistant enameled wire. In this embodiment, the corona-resistant time of the enameled wire at different temperatures is measured under the first lo...

Embodiment 2

[0100] 1. Using corona-resistant enameled wire with a conductor of 0.60mm and a paint film thickness of 74±1um as raw materials, under the condition of a load voltage of 3.5kV, test its temperature at different temperatures (175°C, 155°C, 135°C, 115°C, ℃) The corona resistance time of the sample;

[0101] 2. Refer to the national standard corona resistance time data selection principle, arrange the corona resistance time from small to large, take the average value of the first value and the third value as the corona resistance time of the sample; the above corona resistance The corona resistance time of enameled wire at different temperatures is shown in Table 6:

[0102] Table 6: Corona resistance time of enameled wire at different temperatures

[0103]

[0104] Select the default fitting equation as:

[0105] t=Ae B / T

[0106] Take the logarithm based on e on both sides of the equation to get: Ln(t)=B×1 / T+Ln(A);

[0107] Take the reciprocal (1 / T) and logarithm (Ln(t)...

Embodiment 3

[0122] Adopt the test condition identical with embodiment two, change preset fitting equation into t=kT-n, repeat test step and obtain the fitting relation of T and U as:

[0123] Ln(t)=-2.166Ln(T)+11.368

[0124] t=e-2.166Ln(T)+11.368

[0125] =T-2.166×e11.368

[0126] =86508.67×T-2.166

[0127] Where k=86508.67, n=-2.166

[0128] The process of solving k and n in this embodiment is similar to the process of solving A and B in embodiment two, making Ln(t)>0, and solving T<190.25

[0129] Therefore, the maximum service temperature of the corona-resistant enameled wire of this specification solved by the fitting equation is about 190.25°C when the load voltage is 3.5kV.

[0130] In addition, keeping other conditions unchanged, both sides of the preset fitting equation t=AeB / T, t=kT-n, etc. can be taken as logarithms with any positive integer as the base, such as Log2(t), Log3(t) , Log4(t), Log5(t), Logn(t) (where n is an integer greater than 1), etc.

[0131] In addition,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com