Bridge crane model prediction control method based on data driving

A technology of model predictive control and bridge cranes, applied in the direction of adaptive control, general control system, control/regulation system, etc., to achieve the effect of fast and accurate positioning, high application value, and anti-swing control goals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any transformation or replacement based on the teaching of the present invention belongs to the protection scope of the present invention.

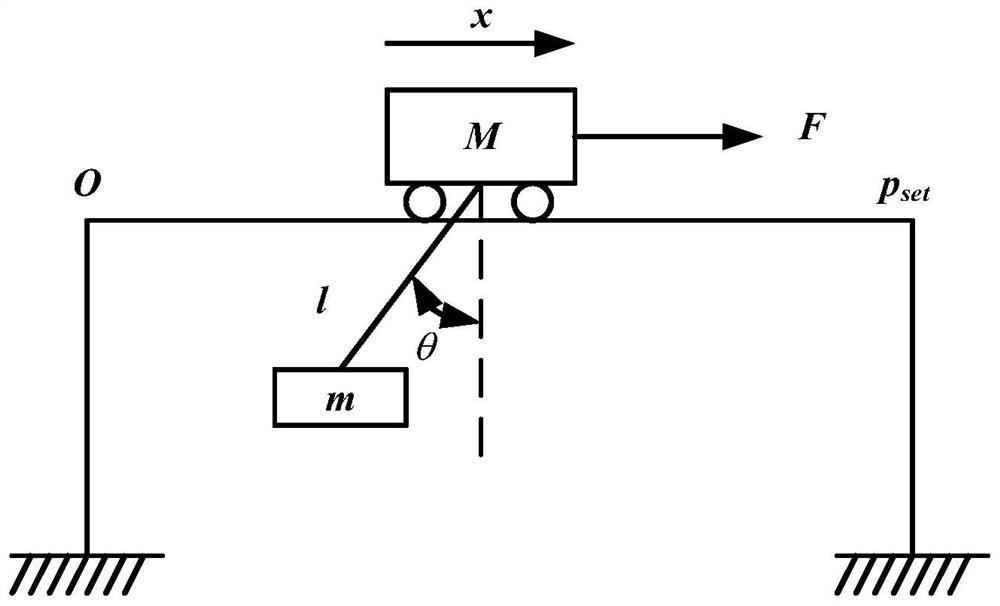

[0057] The overall structure of the bridge crane includes two parts: trolley operating mechanism and lifting mechanism. The trolley running mechanism can be divided into two parts: a large trolley and a small trolley. The trajectories of the small car and the big car are perpendicular to each other. The trolley is responsible for translating the entire overhead crane along the elevated rails on both sides of the production line. It is responsible for the translation on the bridge, and the load lifting mechanism is responsible for completing the lifting movement of the load. According to the crane industry specification, a complete crane operation process generally includes the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com