Nib-3-tin superconducting magnet with quench protection and manufacturing method of Nib-3-tin superconducting magnet

A technology for superconducting magnets and quench protection, which is applied in the manufacture of superconducting magnets/coils, magnetic objects, inductors/transformers/magnets, etc. It can solve problems such as heater deformation and insulation level degradation, and achieve improved efficiency and insulation performance Reliable and reduce the effect of heat loss to the outside

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

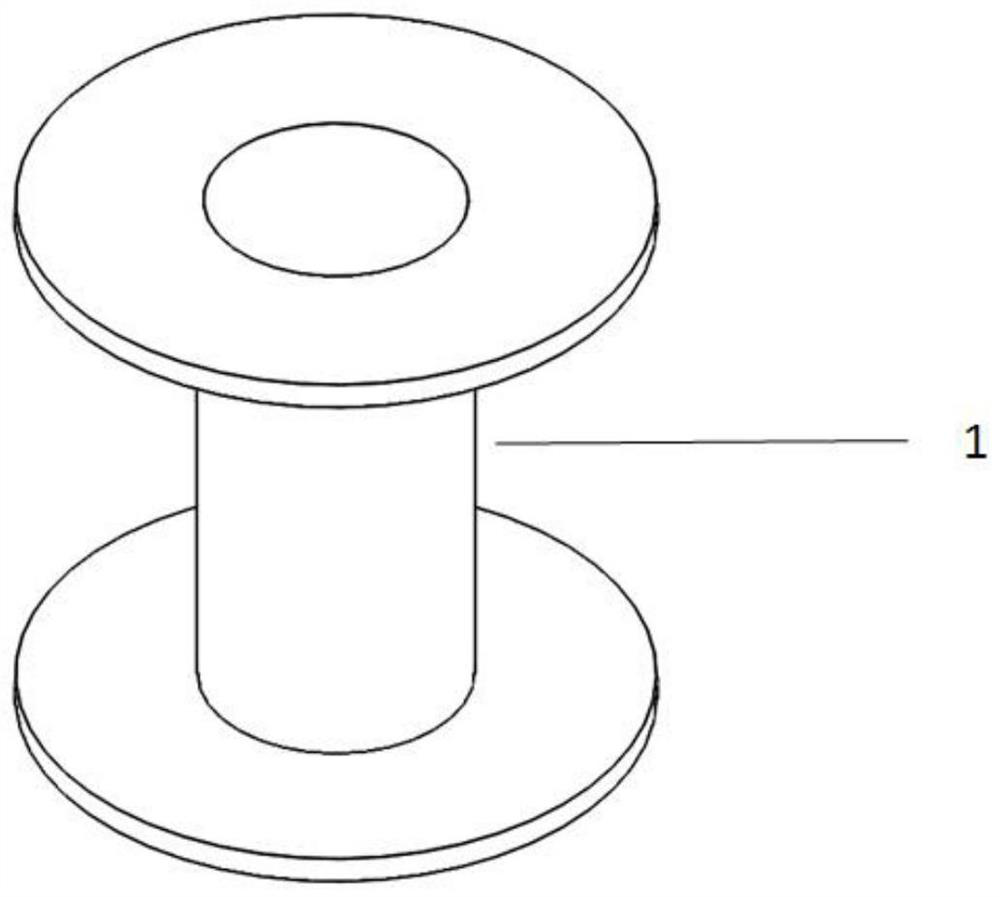

[0060]Winding the niobium-three-tin superconducting magnet 5 on the superconducting magnet skeleton 1, winding a layer of glass cloth insulating layer on the outer surface of the niobium-three-tin superconducting magnet 5; the first heater 2 Attached to the outer surface of the niobium-tritin superconducting magnet 5 in the axial direction; place the heater tooling 4 in the axial direction on the first heater 2, and the heater tooling 4 is parallel to the first heater 2 Placement, the first heater 2 is placed in two grooves on the inner surface of the heater tooling 4; a hexagon socket head screw is installed in the threaded hole on the outer surface of the heater tooling 4, and the hexagon socket head screw is screwed into the In the groove on the inner surface of the heater tooling 4; the binding layer is wound on the niobium-tritin superconducting magnet 5 and the heater tooling 4, and the material of the binding layer includes stainless steel wire or copper wire . The bin...

Embodiment 2

[0062] Winding the niobium-three-tin superconducting magnet 5 on the superconducting magnet skeleton 1, winding a layer of glass cloth insulating layer on the outer surface of the niobium-three-tin superconducting magnet 5; the first heater 2 Attached to the outer surface of the niobium-tritin superconducting magnet 5 in the axial direction; place the heater tooling 4 in the axial direction on the first heater 2, and the heater tooling 4 is parallel to the first heater 2 Placement, the first heater 2 is placed in two grooves on the inner surface of the heater tooling 4; a hexagon socket head screw is installed in the threaded hole on the outer surface of the heater tooling 4, and the hexagon socket head screw is screwed into the In the groove on the inner surface of the heater tooling 4; the binding layer is wound on the niobium-tritin superconducting magnet 5 and the heater tooling 4, and the material of the binding layer includes stainless steel wire or copper wire . The bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com