A connection method of second-generation high-temperature superconducting tape and superconducting wire

A technology of high-temperature superconducting strips and connecting methods, which is applied in the usage of superconducting elements, superconducting/high-conducting conductors, connecting, etc., can solve the problems of poor mechanical properties of superconducting joints, shorten the preparation time of joints, etc., and achieve the improvement of mechanical properties. Strength, shortening recovery time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

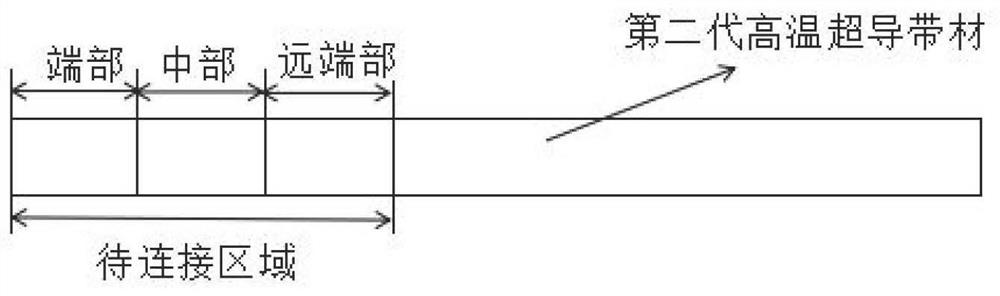

[0068] The connection method of the second-generation high-temperature superconducting strips comprises the following steps:

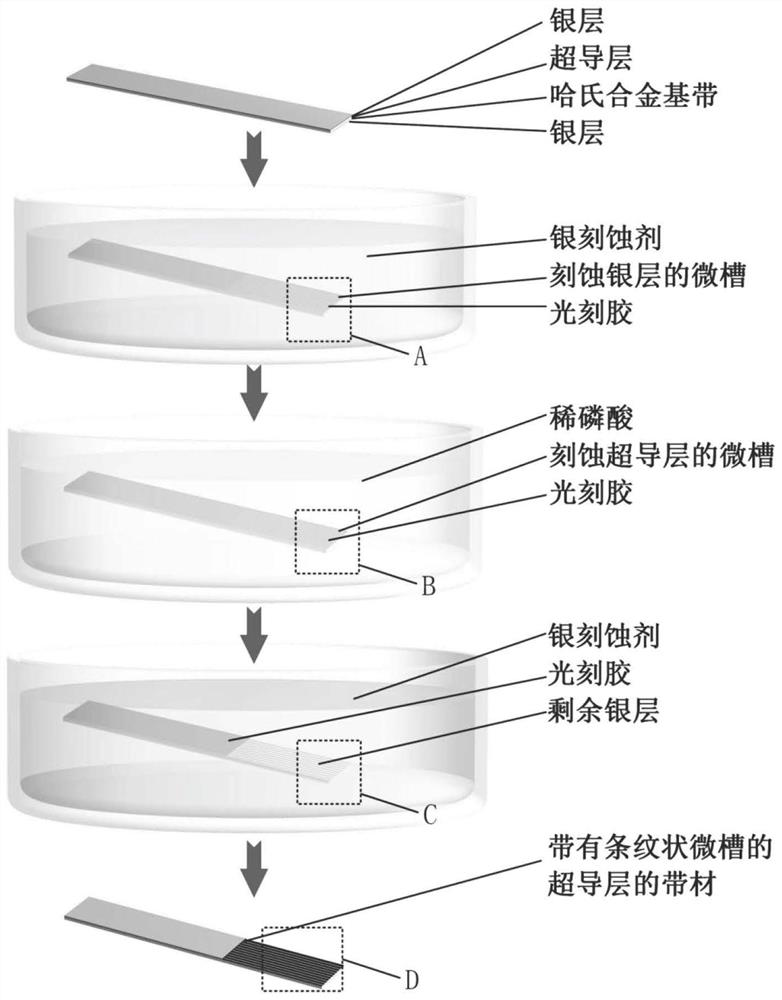

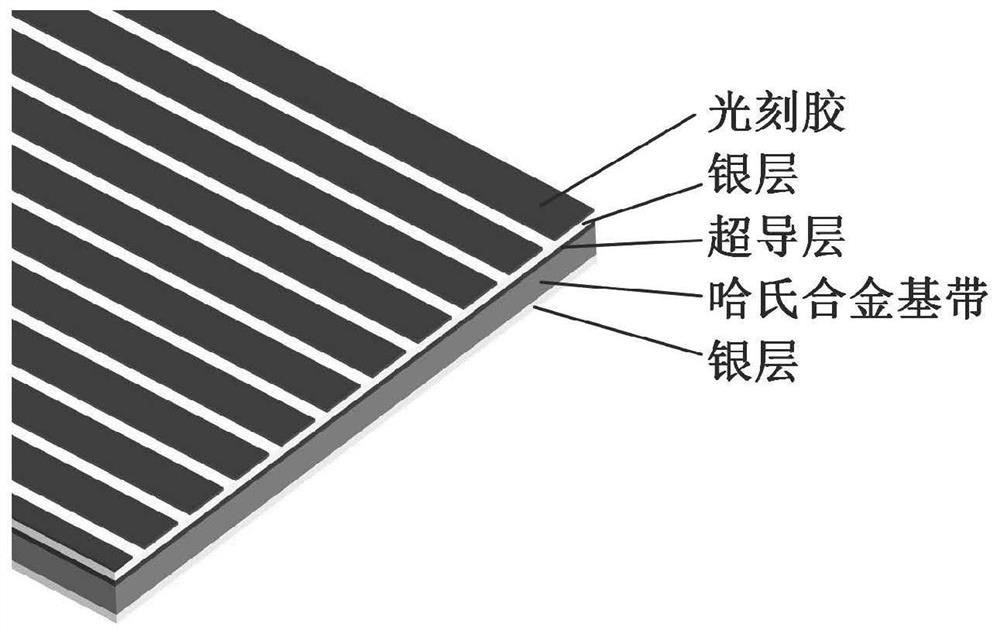

[0069] Use acetone to clean the oil stains on the surface of the area to be connected of two yttrium barium copper oxide (YBCO) superconducting strips, apply photoresist, and immerse in silver etchant after pre-baking, exposure, development, cleaning and post-baking Etch microgrooves with a width of 20 μm and an interval of 200 μm along the length of the superconducting tape and expose the underlying superconducting layer; after rinsing with deionized water, immerse in dilute phosphoric acid to etch the microgrooves of the superconducting layer to remove the striped microgrooves The remaining photoresist on the surface exposes the silver layer with striped microgrooves in the area to be connected, and then immerses in the silver etchant to remove the silver layer in this area, so that the superstructure with striped microgrooves underneath The conducti...

Embodiment 2

[0073] Superconducting wires are prepared in the same manner as in Example 1, except that the second-generation high-temperature superconducting tape is set to gadolinium barium copper oxide (GdBCO), and the etching width is set to 1 μm and 300 μm in microgrooves; the welding of the superconducting layer Conditions are set to vacuum to 5000Pa (P O2 About 1000Pa), apply a pressure of 50MPa, and raise the temperature of this area to 750°C and keep it for 120min; change the condition of oxidation annealing to an oxygen environment of 15MPa, and anneal at 600°C for 50h.

Embodiment 3

[0075] Superconducting wires were prepared in the same manner as in Example 1, except that the second-generation high-temperature superconducting tape was set to yttrium gadolinium barium copper oxide (YGdBCO), and the etching width was set to 50 μm with a microgroove interval of 500 μm; Welding conditions are set to fill with argon (P O2 About 0Pa), apply a pressure of 1MPa, and raise the temperature of the area to 950°C and keep it warm for 0.5min; change the conditions of oxidation annealing to an oxygen environment of 0.1MPa, and anneal at 400°C for 300h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com