Connecting method of second-generation high-temperature superconducting tape and superconducting wire

A technology of high-temperature superconducting tape and connection method, which is applied in the usage of superconducting elements, conductive connection, superconducting/high-conducting conductor, etc., can solve the problems of poor mechanical properties of superconducting joints, etc. Effect of time, high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

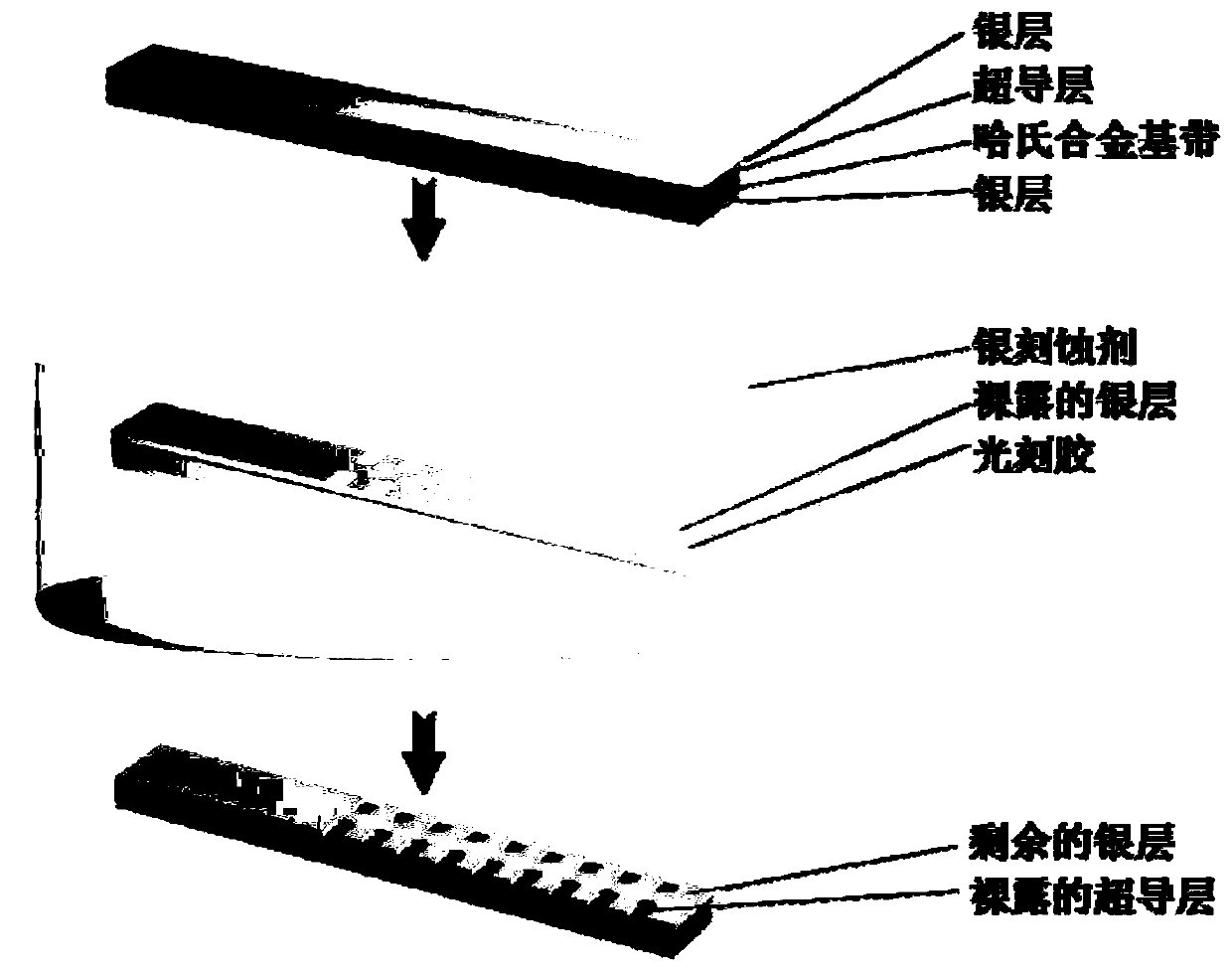

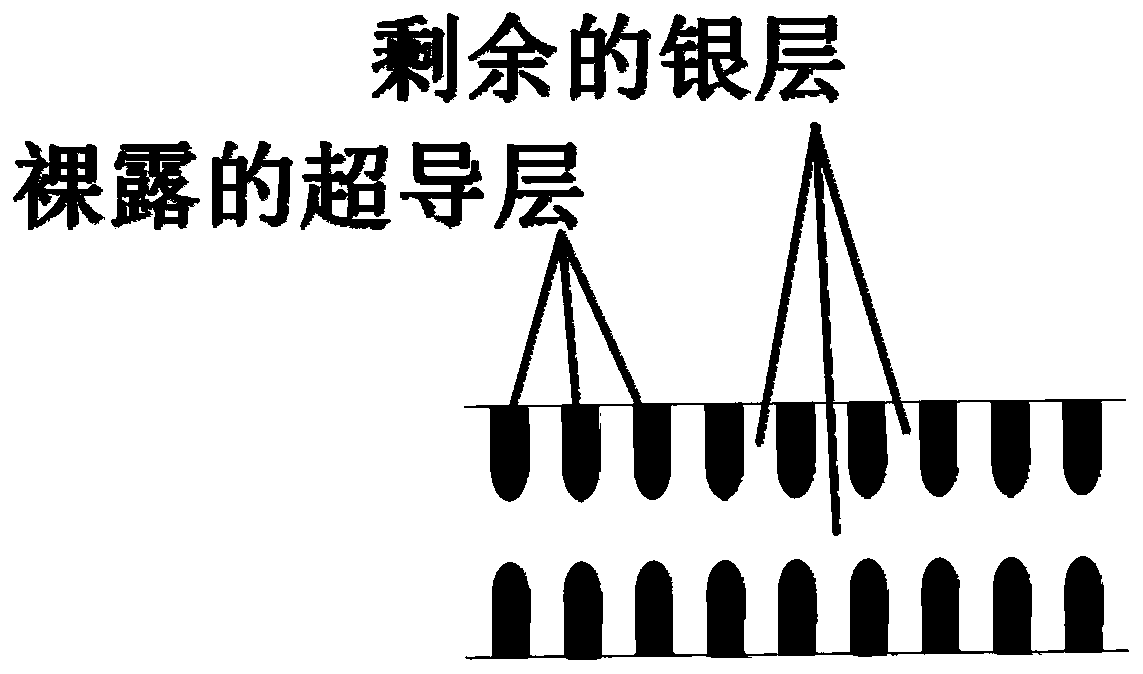

[0041] a. Remove the silver layer in some areas: Clean the oil on the surface of the area to be connected of two yttrium barium copper oxide (YBCO) superconducting strips with acetone, apply photoresist, and perform pre-baking, exposure, development, cleaning and post-baking Afterwards, immerse in the silver etchant to remove the silver layer in the specified area, then remove the residual photoresist and dry it, so that the remaining silver layer in the area to be connected is evenly distributed and a striped pattern in which the silver layer and the superconducting layer are spaced apart from each other is obtained.

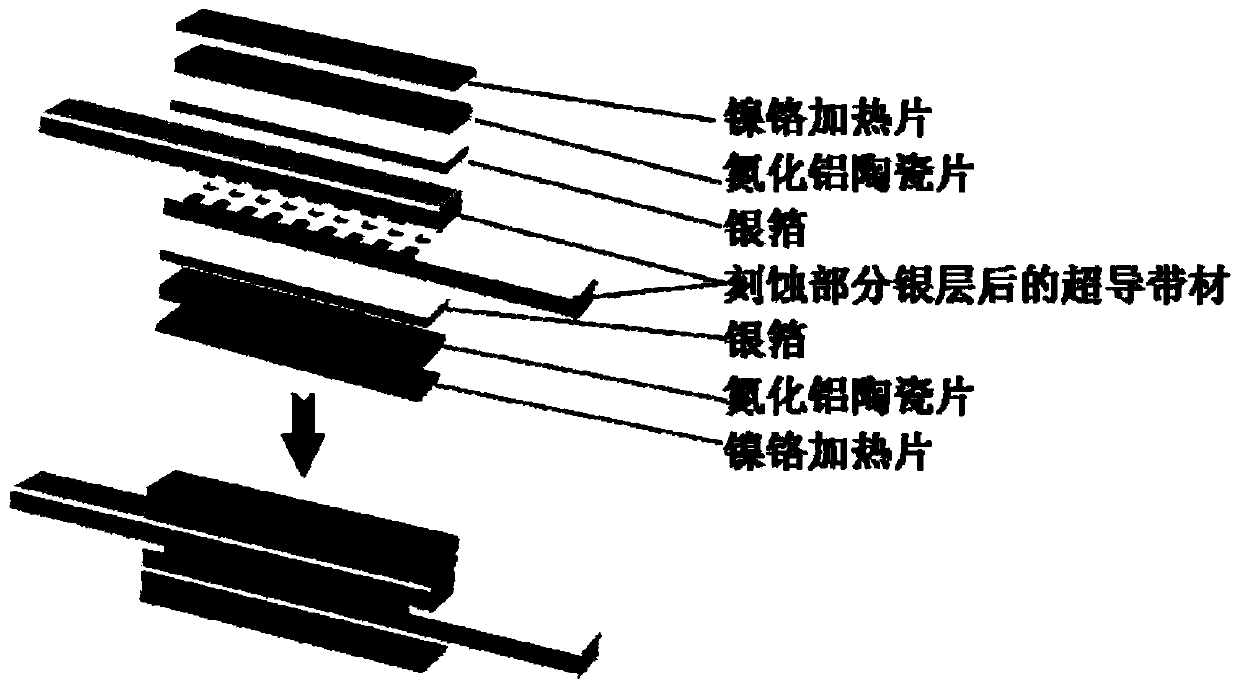

[0042] b. Diffusion welding of the silver layer in the remaining part of the area: after the remaining silver layers in the area to be connected of the two yttrium barium copper oxide (YBCO) superconducting strips processed in step a are overlapped and overlapped, the two sides of the overlapped portion are overlapped. The inside and outside are respectively cla...

Embodiment 2

[0051] a. Remove the silver layer in some areas: Clean the oil on the surface of the area to be connected of two yttrium barium copper oxide (YBCO) superconducting strips with acetone, apply photoresist, and perform pre-baking, exposure, development, cleaning and post-baking Afterwards, immerse in the silver etchant to remove the silver layer in the specified area, then remove the residual photoresist and dry it, so that the remaining silver layer in the area to be connected is evenly distributed and a striped pattern in which the silver layer and the superconducting layer are spaced apart from each other is obtained.

[0052] b. Diffusion welding of the silver layer in the remaining part of the area: after the remaining silver layers in the area to be connected of the two yttrium barium copper oxide (YBCO) superconducting strips processed in step a are overlapped and overlapped, the two sides of the overlapped portion are overlapped. The inside and outside are respectively cla...

Embodiment 3

[0059] a. Remove the silver layer in some areas: Clean the surface oil stains in the area to be connected of two yttrium gadolinium barium copper oxide (YGdBCO) superconducting strips with acetone, and then apply photoresist. After pre-baking, exposure, development, cleaning and post-baking After baking, immerse in the silver etchant to remove the silver layer in the specified area, and then remove the residual photoresist and dry it, so that the remaining silver layer in the area to be connected is evenly distributed and a stripe pattern in which the silver layer and the superconducting layer are spaced apart is obtained.

[0060] b. Diffusion welding of the silver layer in the remaining part area: after the remaining silver layers in the area to be connected of the two yttrium gadolinium barium copper oxide (YGdBCO) superconducting strips processed in step a are superimposed and lapped, on both sides of the lapped part From the inside to the outside, silver foil, aluminum nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com