Track chain component with hardfacing wire covering layer

A technology for surfacing welding wire and crawler chain, which is applied to crawler vehicles, vehicle parts, solid diffusion coating and other directions, and can solve problems such as limiting the thickness of the outer layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

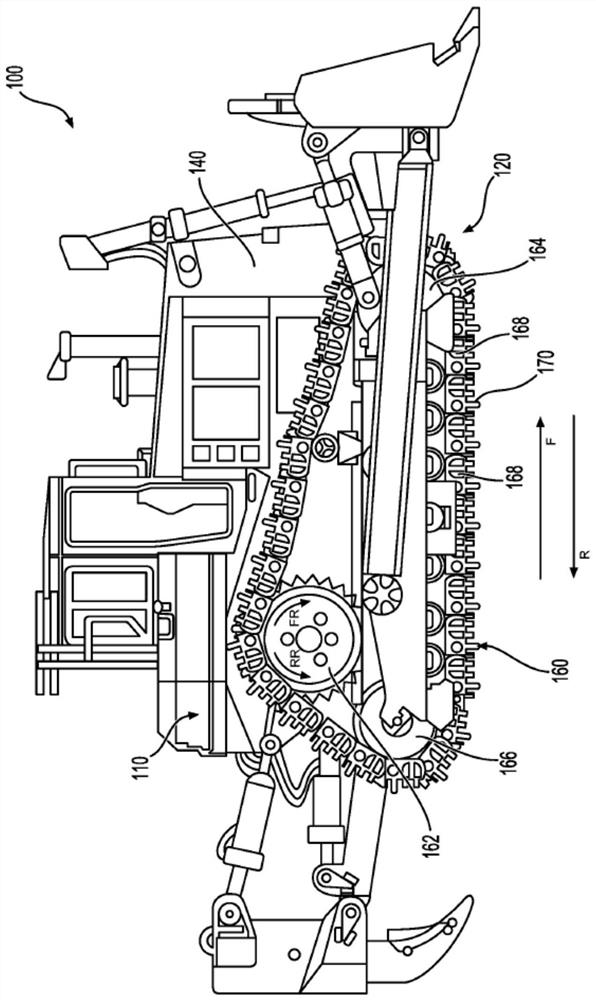

[0018] figure 1 is a schematic diagram of an exemplary system including a tracked machine 100 having one or more components formed in accordance with an exemplary embodiment of the invention. The exemplary embodiment of machine 100 includes a tracked undercarriage 120 . Machine 100 is also referred to herein interchangeably as "tracked machine" 100 and / or "machine" 100 . In other embodiments, machine 100 may be any suitable machine having tracked undercarriage 120, such as a bulldozer, loader, excavator, tank, backhoe, drill, trencher, or any other on-road or off-road vehicle. road vehicle.

[0019] Machine 100 includes a frame 140 having a first track chain assembly 160 disposed on a first side 110 thereof and a second track chain assembly (not shown) disposed on a second side (not shown) thereof. The second side is in opposing relationship to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com