Nanoscale antibacterial mosquito-repellent microcapsule and preparation method thereof

A microcapsule and nano-level technology, applied in the field of microcapsules, can solve the problems of high cumulative release of microcapsules, low practicability, cumbersome process flow, etc., and achieve the effects of easy promotion and use, high packaging efficiency, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

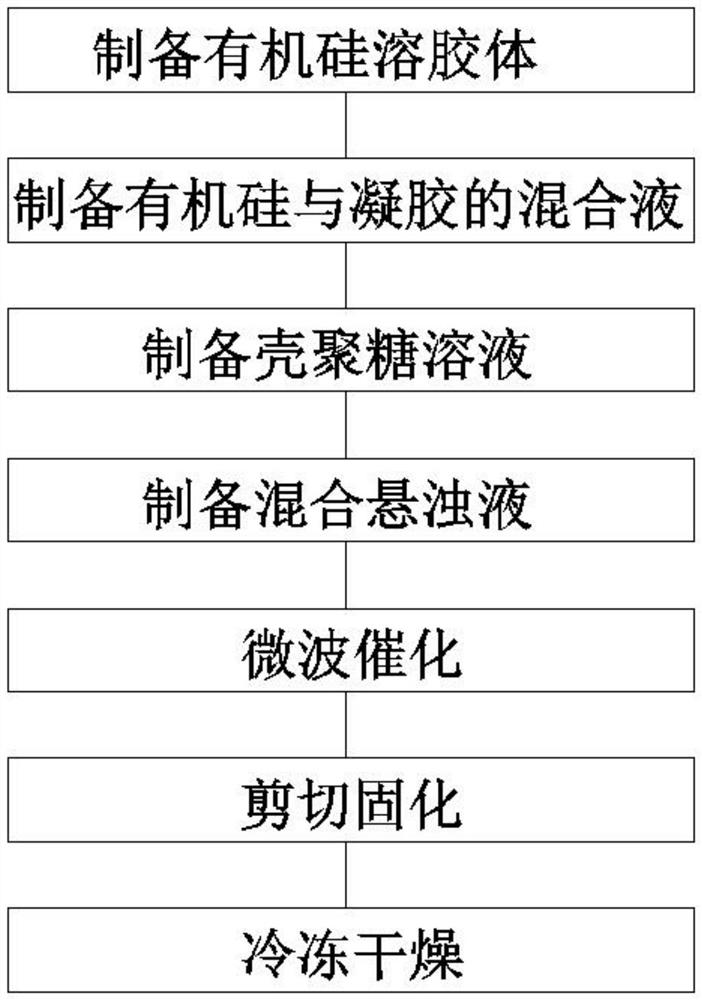

[0023] refer to figure 1 , a nano-scale antibacterial mosquito repellent microcapsule, the raw material components of the antibacterial mosquito repellent microcapsule include organosilicon sol, surfactant, chitosan, mosquito repellent liquid, ethanol and deionized water, and the thickness of the capsule wall is 0.10mm-0.20mm between mm.

[0024] A preparation method of nanoscale antibacterial mosquito repelling microcapsules, comprising the following steps:

[0025] S1: Add deionized water with a capacity of 30L into the container, control the temperature at 80°C, and add 60g of organosilicon sol to it while stirring the deionized water continuously until the organosilicon sol is formed;

[0026] S2: Add a gelling agent and a coagulant to the organosilicon sol for stirring and mixing, and obtain a silicone gel mixture after thorough mixing. The gelling agent is a mixture of cellulose gum and alginate, and the coagulation aid is A mixture of potassium chloride and sodium chl...

Embodiment 2

[0033] refer to figure 1 , a nano-scale antibacterial mosquito repellent microcapsule, the raw material components of the antibacterial mosquito repellent microcapsule include organosilicon sol, surfactant, chitosan, mosquito repellent liquid, ethanol and deionized water, and the thickness of the capsule wall is 0.10mm-0.20mm between mm.

[0034] A preparation method of nanoscale antibacterial mosquito repelling microcapsules, comprising the following steps:

[0035] S1: Add deionized water with a capacity of 40L to the container, control the temperature at 60°C, and add 90g of organosilicon sol to it while stirring the deionized water continuously until the organosilicon sol is formed;

[0036] S2: Add a gelling agent and a coagulant to the organosilicon sol for stirring and mixing, and obtain a silicone gel mixture after thorough mixing. The gelling agent is a mixture of cellulose gum and alginate, and the coagulation aid is A mixture of potassium chloride and sodium chlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com