Interlocking and shear-resistant segment connection structure for assembly of initial receiving segment segment ring

A technology for connecting structures and segments, applied in wind power generation, shaft equipment, wellbore lining, etc., can solve the problems of damage, complicated installation process, large smoke, harmful gas and noise pollution, etc., to ensure the bearing capacity and durability, The inner and outer walls are flat and the structure is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

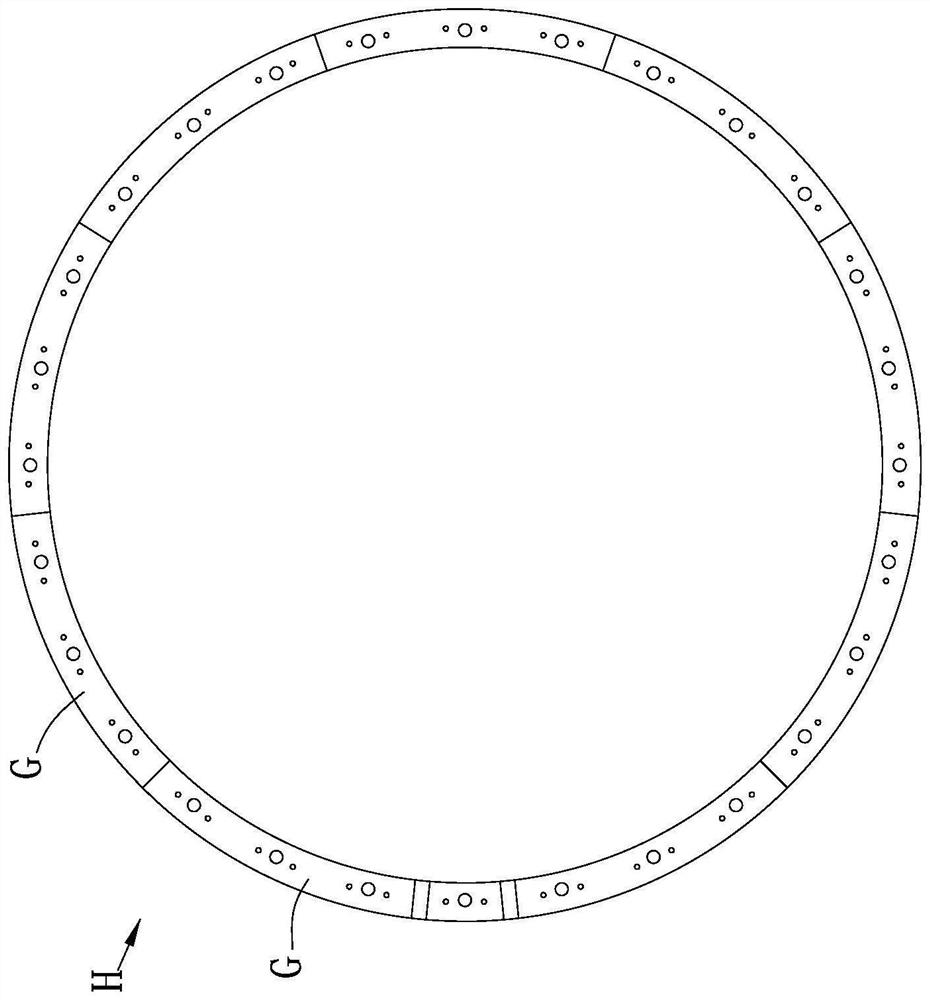

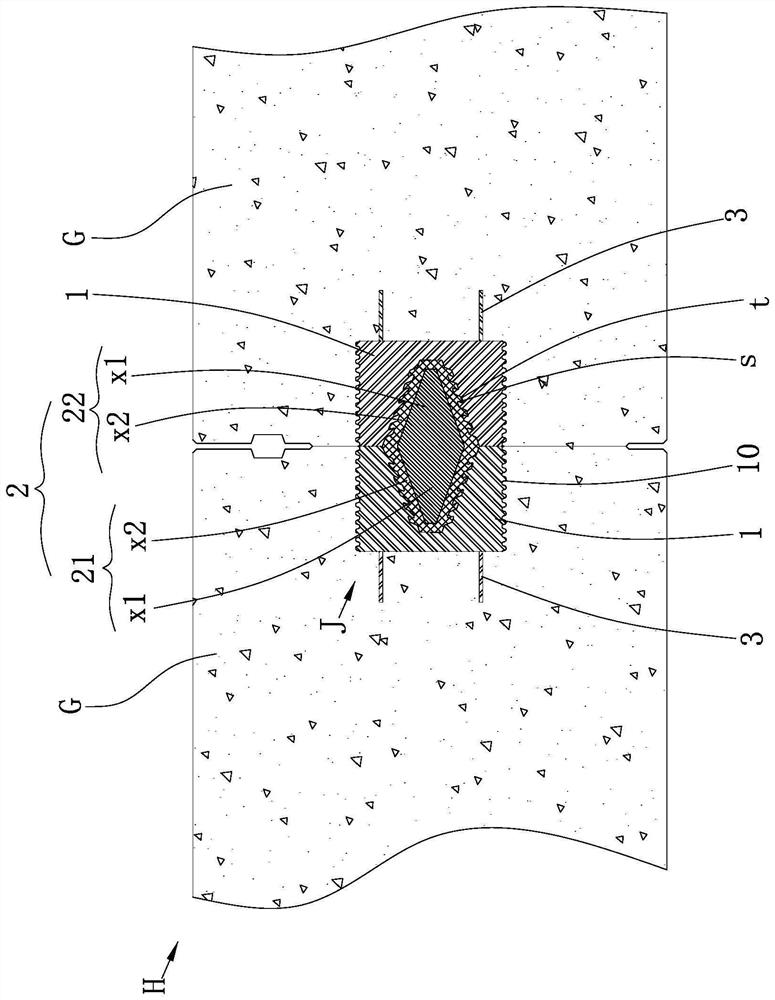

[0043] Such as figure 1 and figure 2 As shown, the interlocking and shear-resistant segment connection structure J for segment ring assembly in the starting and receiving section of this embodiment is used for left and right splicing of two segments G from the vertical end face, and its Finally, the segment ring H is formed.

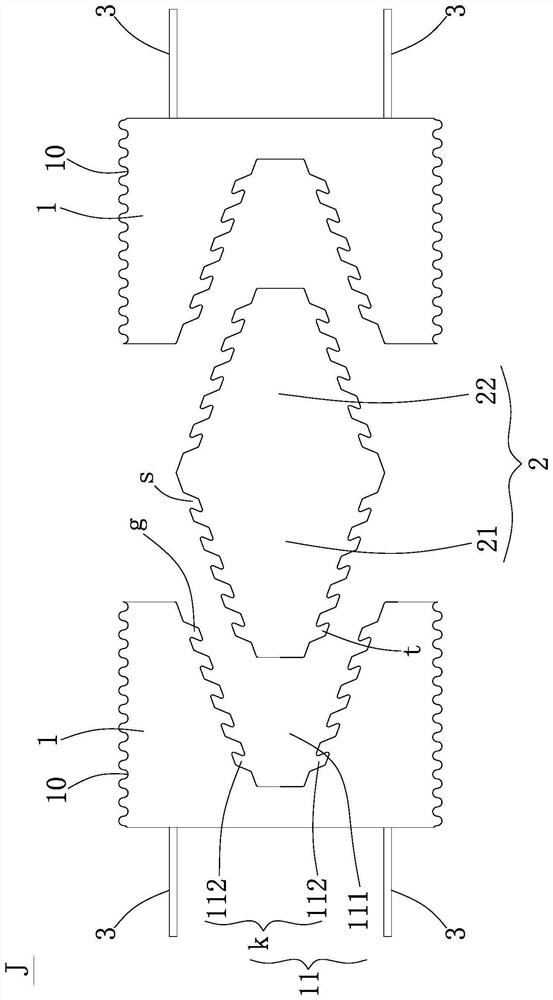

[0044] Specifically, the segment connecting structure J includes two pre-embedded inner sleeves 1 and connecting inner cores 2 that are symmetrically arranged from the splicing seam of two segments G.

[0045] combine image 3 and Figure 4 As shown, the pre-embedded inner sleeve 1 is pre-embedded at the end of the segment G to be spliced, and is integrally formed with the segment G.

[0046] In this example, an alveolar 10 is formed on the outer periphery of the embedded inner sleeve 1, and is embedded in the center where the end of the segment G is located, wherein the inner end of the embedded inner sleeve 1 is also provided with a The pre-embed...

Embodiment 2

[0070] Such as Figure 5 and Figure 6 As shown, the interlocking and shear-resistant segment connection structure J used in this embodiment for the segment ring assembly of the starting and receiving section is used for splicing two segments G up and down from the horizontal end surface. It eventually forms the segment ring H.

[0071] Specifically, the structures of the pre-embedded inner casing 1 and the connecting inner core 2 are basically the same as those of the first embodiment.

[0072] The difference is that in this example, the mandrel x1 and the core sleeve x2 connecting the first core 21 and the second core 22 of the inner core 2 are made of the same material, and the first core 21 and the second core 22 are integrated shaped.

[0073] In this example, the material of the connecting inner core 2 is industrial plastic, which is fire-resistant and corrosion-resistant, and is not prone to rust in the humid environment of the tunnel or when water seepage occurs.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com