Power station boiler abnormal working condition detection method and system

A technology for abnormal working conditions, power station boilers, applied in measurement devices, fluid velocity measurement, velocity/acceleration/impact measurement, etc., can solve the problems of uneven distribution, unplanned shutdown, uneven flow velocity distribution, etc. degree, accurate detection and determination of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

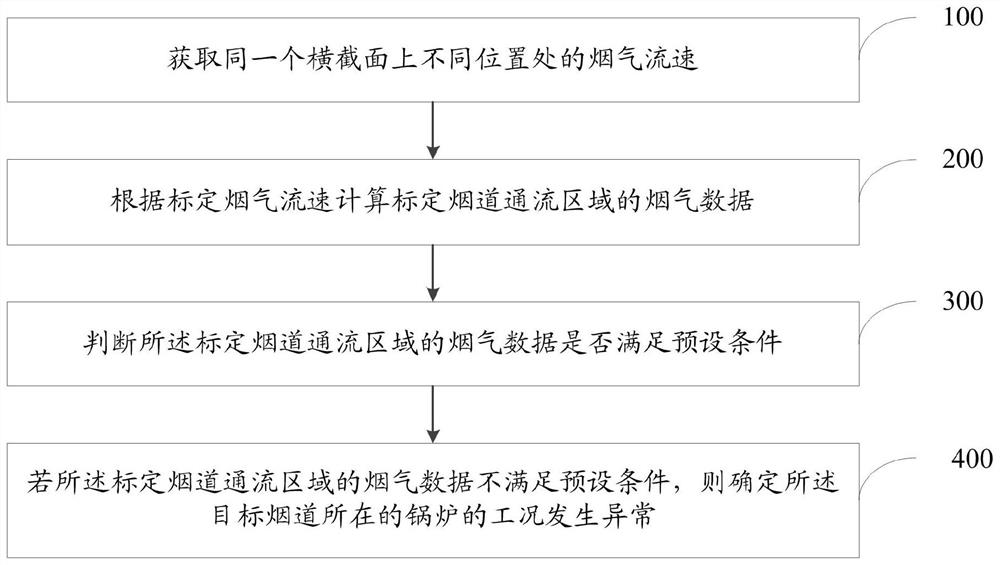

[0073] Such as figure 1 As shown, this embodiment provides a method for detecting abnormal working conditions of a power plant boiler, the method comprising:

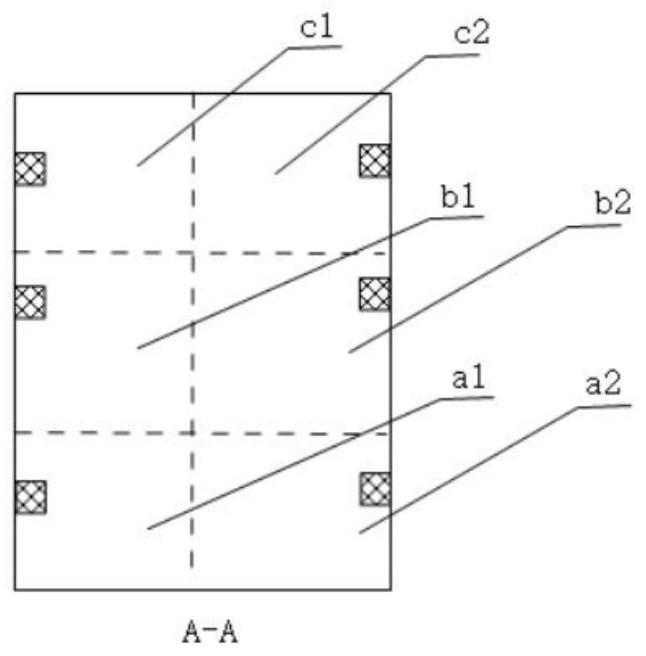

[0074] Step 100, obtaining the smoke flow velocity at different positions on the same cross section; the cross section is the cross section of the target flue to be detected; the smoke flow velocity is determined by the flow velocity detection component arranged on the target flue of. Specifically, the flow velocity detection component is a high-temperature wind velocity sensor, which uses a Pitot tube to simultaneously measure the dynamic pressure and static pressure of the flue gas, and then calculate the flow velocity of the flue gas. The stainless steel pitot tube of the pitot tube wind speed sensor has a temperature resistance of 1000°C, and is suitable for use in the horizontal flue of the boiler and all flue environments at the rear of the boiler.

[0075] In a specific embodiment, before the final stage reheat...

Embodiment 2

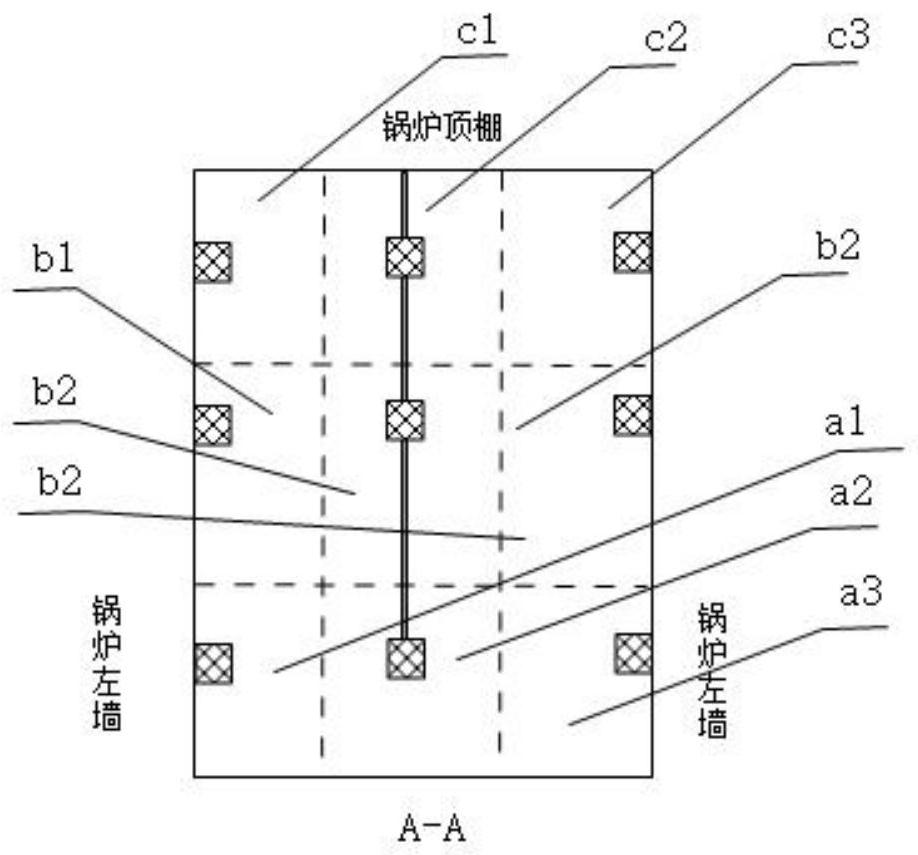

[0108] Such as Figure 4 As shown, this embodiment provides a system for detecting abnormal working conditions of a power plant boiler, and the system includes:

[0109] The flow velocity acquisition module 101 is used to acquire the smoke flow velocity at different positions on the same cross section; the cross section is the cross section of the target flue to be detected; the smoke flow velocity is set on the target flue determined by the flow rate detection component.

[0110] The flue gas data calculation module 201 is used to calculate the flue gas data of the calibrated flue flow area according to the calibrated flue gas flow rate; the flue gas data includes the flue gas flow rate, ash deposition risk value, wind speed deviation value and wear value; The calibrated flue flow rate is any flue flow rate; the cross-section includes a plurality of flue flow areas; the calibrated flue flow area is any flue flow area, and the calibrated flue flow The area is the flue gas pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com