Efficient quantitative characterization method for complex-phase steel body-centered cubic structure phase

A body-centered cubic, quantitative characterization technology, which is applied to the improvement of process efficiency, measurement devices, and preparation of test samples. It can solve problems such as low resolution, unstable techniques, and inability to meet quantitative characterization requirements, and achieve streamlined experiments. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

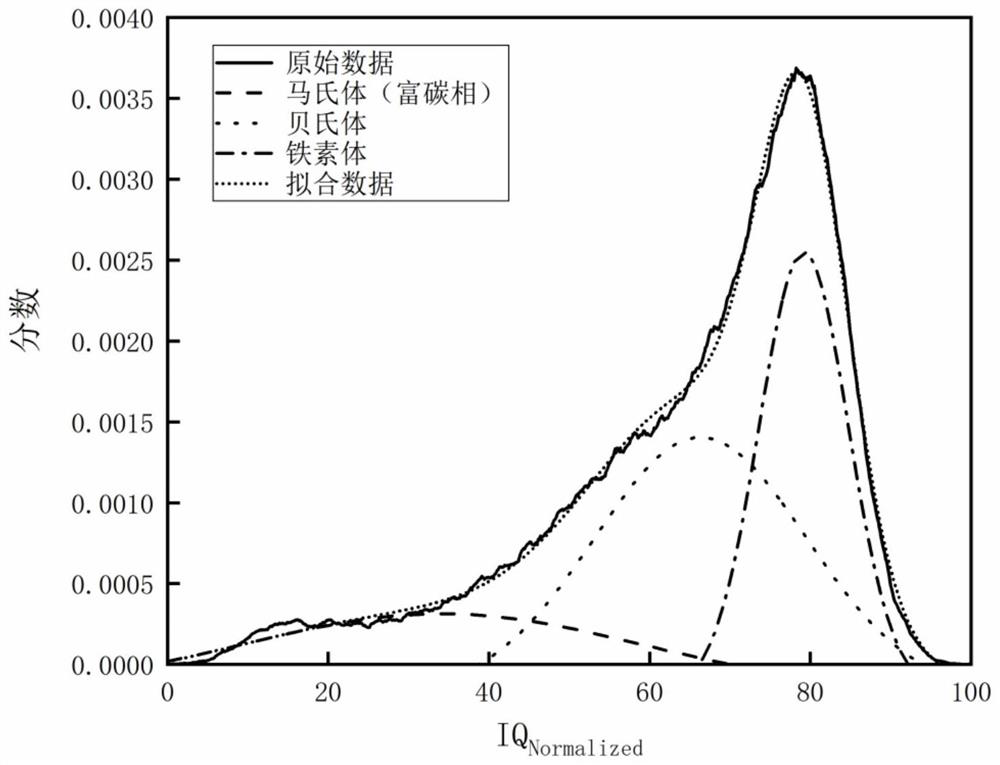

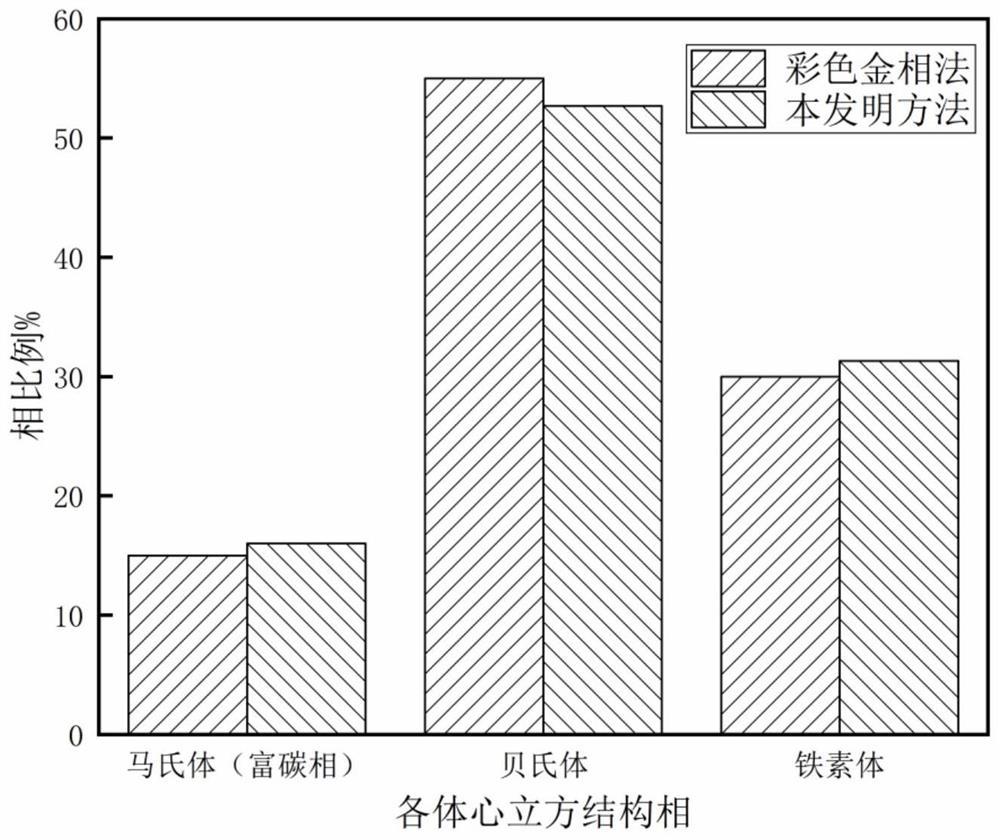

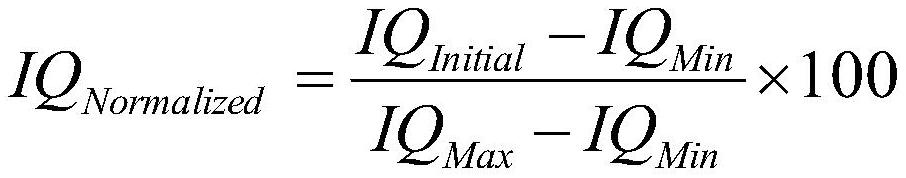

[0031] The invention provides an efficient quantitative characterization method for the body-centered cubic structural phase of complex phase steel.

[0032] The method includes steps as follows:

[0033] S1: Metallographic sample preparation: according to the national standard metal microstructure inspection method GB / T 13298-2015, cut the composite phase steel into suitable size samples, and polish the surface of the sample to be observed according to the national standard method, use Corrosion with corrosive solution, and then polished to obtain a metallographic surface, and further cleaned and dried with alcohol to obtain a metallographic sample;

[0034] S2: Electropolishing of the sample: Electropolish the metallographic sample obtained in S1 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com