Hydraulic turbine design method based on axial surface speed and entropy increase analysis and hydraulic turbine

A technology of hydraulic turbine and design method, applied in the field of turbine, can solve the problems of large hydraulic loss, cumbersome hydraulic design process, unsmooth connection at the elbow of the flow channel, etc. Loss, effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but do not limit it in any way.

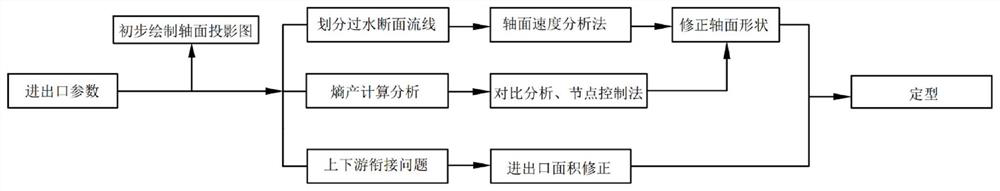

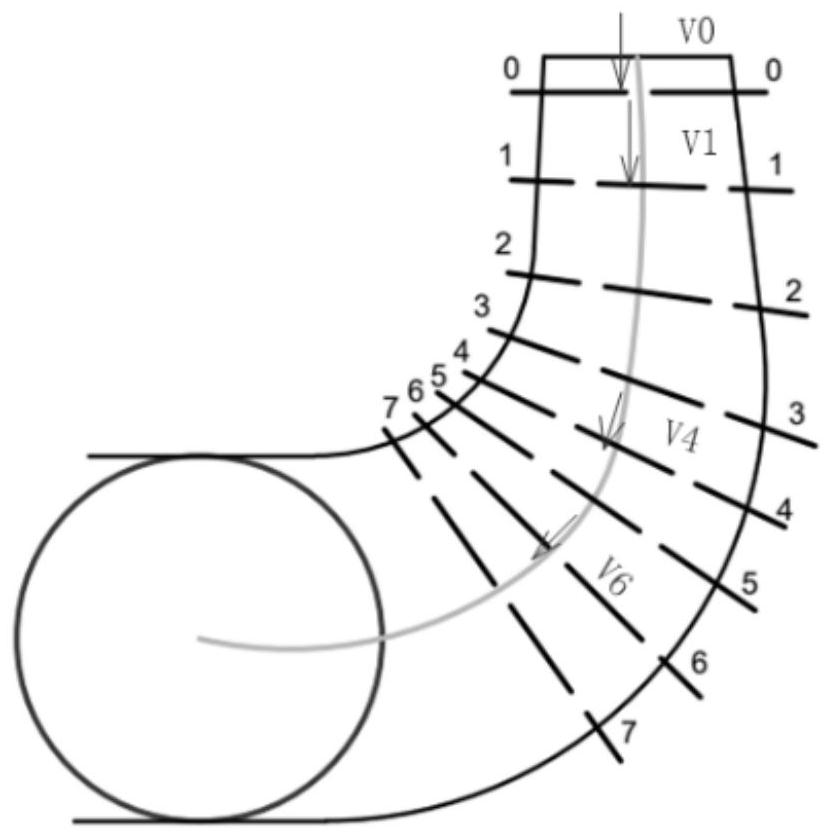

[0058] The hydraulic turbine joint design method based on the axial surface velocity and entropy increase analysis of the present invention is used to determine the axial surface profile of the hydraulic turbine. The basic principle is to correct the area of the flow section through the axial surface velocity, and obtain Transition cross-section shape, and then through entropy increase to analyze the location of significant energy loss, and finally through precise hydraulic control at this point, an efficient flow cross-section shape is obtained.

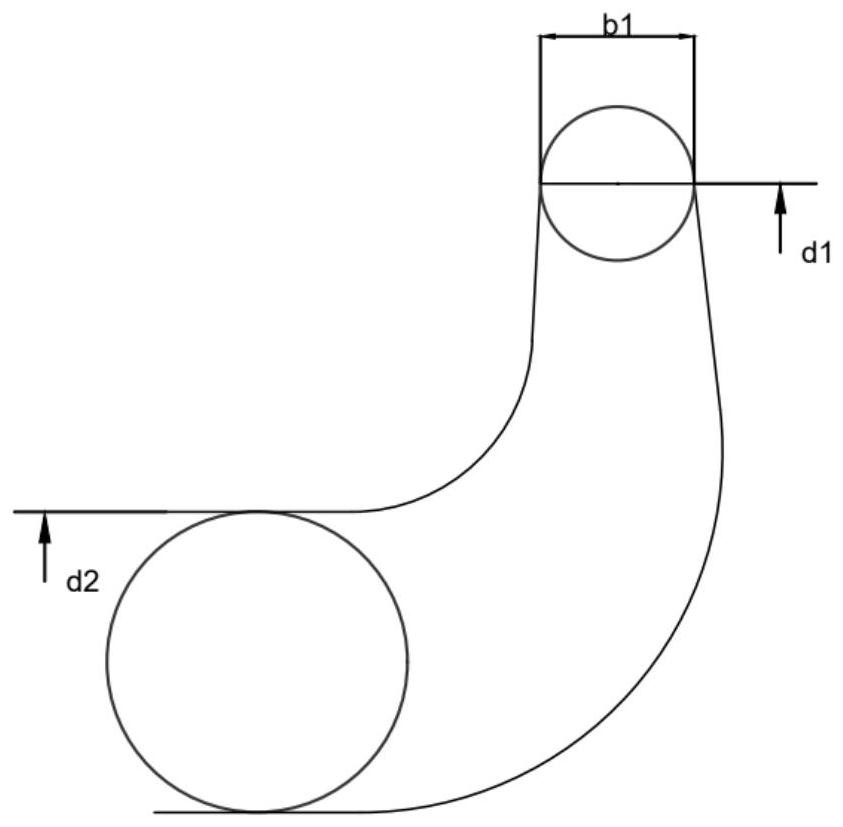

[0059] The turbine has a front cover plate and a rear cover plate, and the front cover plate and the rear cover plate are kept parallel. There are m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com