Aluminum alloy thick plate and preparation method thereof

A technology of aluminum alloy and aluminum alloy ingot, which is applied in metal material coating process, solid-state diffusion coating, coating and other directions, can solve the problems of difficulty in eliminating hydrogen holes, unqualified aluminum alloy thick plate flaw detection, etc. The effect of penetration efficiency, elimination of hole defects, and improvement of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] In order to solve the above problems, in a typical embodiment of the present invention, a method for preparing an aluminum alloy thick plate is provided. alloy, the preparation method includes the following steps: step S1, casting an aluminum alloy ingot and milling the surface to obtain an ingot to be treated with a thickness of 80-500mm; step S2, performing the first heat preservation on the ingot to be processed, and then performing the first Hot rolling to obtain the first billet; step S3, subjecting the first billet to a second heat preservation and hydrogen permeation treatment to obtain a second billet; step S4, performing a third heat preservation on the second billet, and then performing a second hot rolling, and cooling to obtain an aluminum Alloy thick plate; wherein, the temperature of the first heat preservation < the temperature of the second heat preservation, the time of the first heat preservation < the time of the second heat preservation; the temperatu...

Embodiment 1

[0035] Composition of aluminum alloy thick plate: 4.5wt.% Mg, the rest is Al.

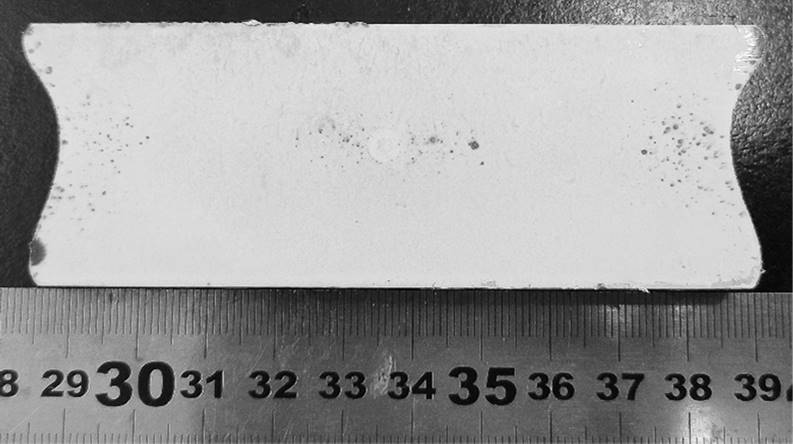

[0036] The size of the ingot is 85 (thick) × 90 × 100mm, and the heat preservation is carried out according to the heat preservation procedure in Table 1. The first hot rolling is through 18 passes of double-rolled hot rolling to 58mm, and the reduction in a single pass is 1.5mm; After rolling through 13 passes to 38.5mm, the reduction in a single pass is 1.5mm, and cooling to obtain a 38.5mm aluminum alloy thick plate. The central section of the aluminum alloy thick plate obtained in Example 1 is sampled for penetrant flaw detection analysis. The flaw detection results are shown in Table 1, and the flaw detection result photos are shown in figure 1 .

Embodiment 2

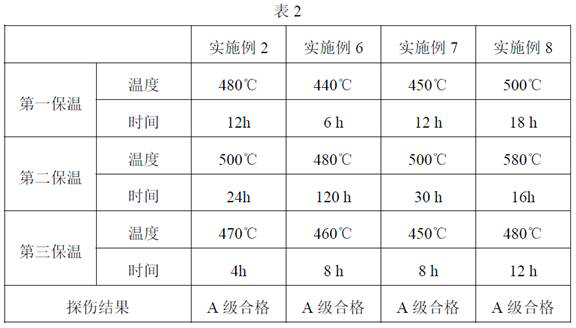

[0038] Composition of aluminum alloy thick plate: 4.5wt.% Mg, 0.9 wt.% Mn, 0.18 wt.% Fe, 0.12 wt.% Si, 0.02wt.% Ti, and the rest is Al.

[0039] The ingot size is 400mm (thick) × 1600 × 2500mm, heat preservation is carried out according to the heat preservation procedure in Table 1, and the first hot rolling passes through a four-roll hot rolling mill with a work roll diameter of 1050mm for 9 passes to form a 220mm thick slab. The pass reduction is 20mm; after the first hot rolling is completed, high-pressure air holes are formed within 300mm of the side of the ingot. 20mm, cooling to get 120mm aluminum alloy thick plate. The aluminum alloy thick plate prepared in Example 2 was subjected to ultrasonic flaw detection, and the flaw detection result was grade A qualified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com