Gas drive reservoir injection-production parameter step-by-step optimization method

An optimization method, gas flooding technology, applied in climate change adaptation, design optimization/simulation, fluid extraction, etc., can solve problems such as limited orthogonal design schemes, time-consuming, and only focus on injection parameters, etc., to reduce related economic Cost, improvement of optimization time, effect of scientific and technical support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0101] Take Tarim actual reservoir CH 4 Taking flooding as an example, the process flow of the method is illustrated.

[0102] In step 1, collect and organize the basic parameters of geological and development data of block H of Tarim oil reservoir: porosity, permeability, saturation, oil layer thickness, pressure, viscosity, relative permeability curve, reservoir well location, injection The historical working system of wells and production wells and other information, the daily gas injection of a single well in this reservoir is about 8000m 3 (The underground volume is about 300m 3 ),Such as Figure 4 The permeability distribution is shown as Figure 5 The porosity distribution shown, as Figure 6 Saturation distribution shown.

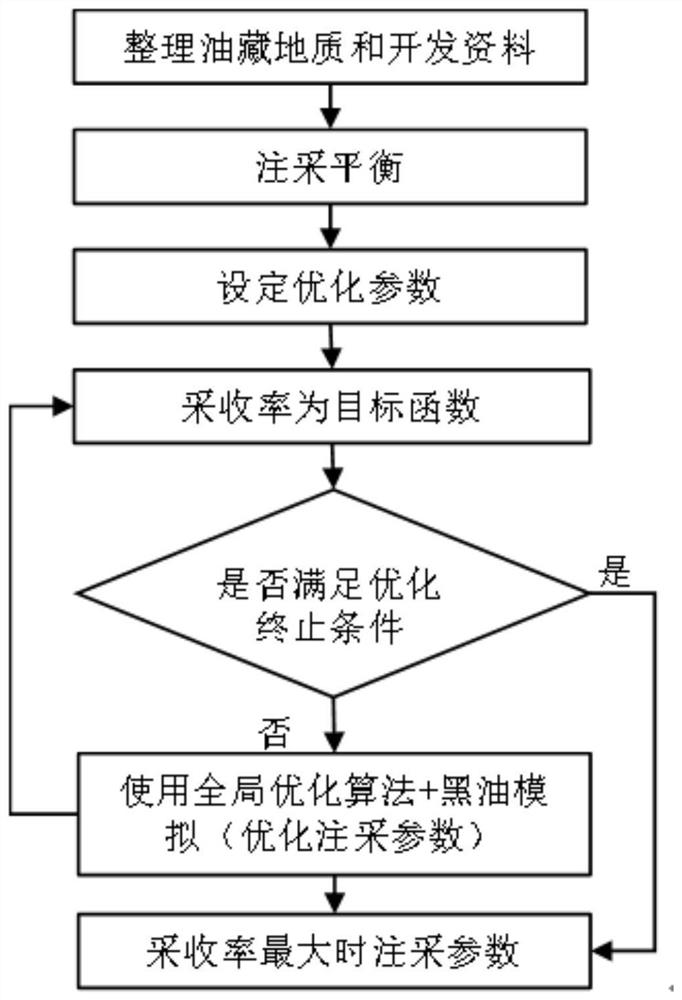

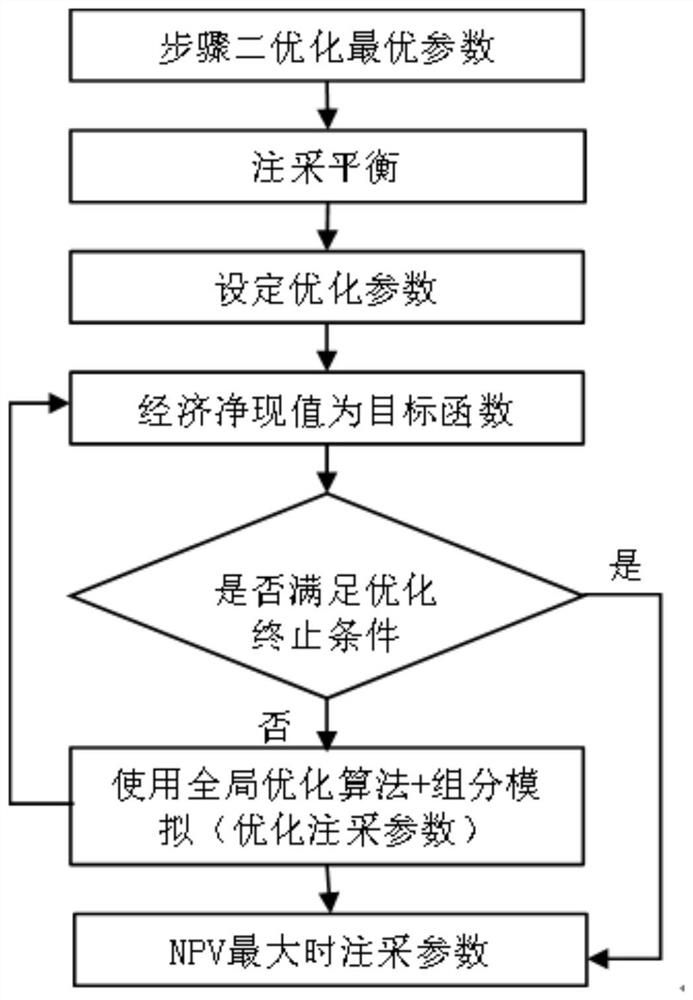

[0103] In step 2, as in figure 2 Shown is the second step flow process of the present invention.

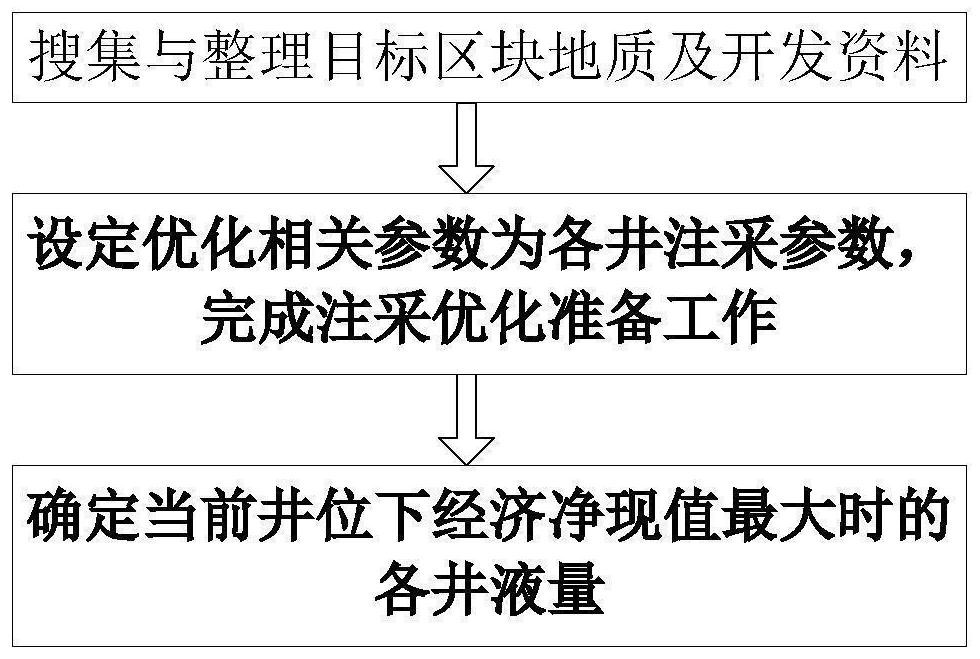

[0104](1) In step (2), the optimization-related parameters are set as the injection-production parameters of each well, and the preparatory wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com