Low-refrigeration-effect composite propellant for inhalation aerosol as well as preparation method and application of low-refrigeration-effect composite propellant

A propellant and unilateral technology, applied in the direction of aerosol delivery, medical preparations of non-active ingredients, pharmaceutical formulations, etc., can solve the problem of drug-containing aerosol settlement and adhesion, reduction of drug dose in the patient's respiratory system, delay in treatment timing, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

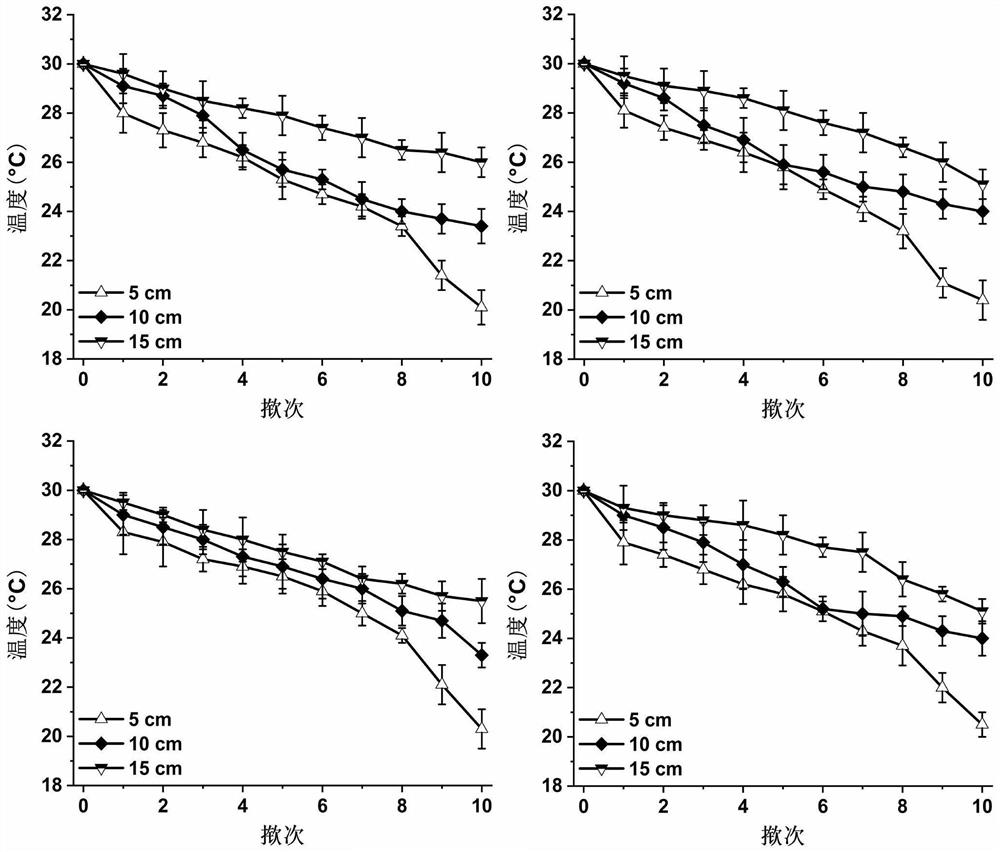

[0077] Example 1: Preparation of glucose-ethanol-HFA134a composite propellant

[0078] Glucose and ethanol were sequentially added to a 10 mL aluminum pressure-resistant container, and then placed in an air-bath stirring box at 25° C. and stirred at a rate of 50 rpm. Then use a sealing machine to install a 50 μL quantitative valve on the pressure-resistant container, and use a propellant filling machine to fill the aluminum pressure-resistant container with HFA134a, and then stir at a rate of 50 rpm in an air bath stirring box at 25 °C.

[0079] Systems 1-4 and A-C were prepared through the above steps. The mass ratio of glucose-ethanol-HFA134a in system 1 is 0.05:5:94.95; the mass ratio of glucose-ethanol-HFA134a in system 2 is 0.1:5:94.9; the mass ratio of glucose-ethanol-HFA134a in system 3 is 0.1:10: 89.9; the mass ratio of glucose-ethanol-HFA134a in system 4 is 0.2:10:89.8; the mass ratio of glucose-ethanol-HFA134a in system A is 0.8:5:94.2; the mass ratio of glucose-eth...

Embodiment 2

[0102] Example 2: Preparation of mannose-tert-butanol-HFA227 composite propellant

[0103] Mannose and tert-butanol were sequentially added to a 10 mL aluminum pressure-resistant container, and the mixture was placed in a 30° C. air-bath stirring box and stirred at a speed of 100 rpm. Then use a sealing machine to install a 50 μL quantitative valve on the pressure-resistant container, fill HFA227 into the aluminum pressure-resistant container with a propellant filling machine, and then stir at a rate of 100 rpm in an air bath stirring box at 30 °C.

[0104] Systems 5-8 were prepared through the above steps. The mass ratio of mannose-tert-butanol-HFA227 in system 5 is 0.01:1:98.99; the mass ratio of mannose-tert-butanol-HFA227 in system 6 is 0.02:1:98.98; the mannose-tert-butanol in system 7 The mass ratio of -HFA227 is 0.02:2:97.98; the mass ratio of mannose-tert-butanol-HFA227 in system 8 is 0.04:2:97.96. The total mass of mannose, tert-butanol and HFA227 in each system is ...

Embodiment 3

[0109] Example 3: Preparation of fructose-ethanol / isopropanol-HFA134a composite propellant

[0110] Fructose, ethanol and isopropanol were sequentially added to a 10 mL aluminum pressure-resistant container, and placed in a 20° C. air-bath stirring box to stir at a rate of 25 rpm. Then use a sealing machine to install a 50 μL quantitative valve on the pressure-resistant container, pour HFA134a into the aluminum pressure-resistant container with a propellant filling machine, and then stir at a rate of 25 rpm in an air bath stirring box at 20 °C.

[0111] Systems 9-14 were prepared by the above steps. The ethanol-isopropanol mass ratio in system 9 is 3:2, the fructose-ethanol / isopropanol-HFA134a mass ratio is 0.01:2:97.99; the ethanol-isopropanol mass ratio in system 10 is 1:1, fructose-ethanol / isopropanol-HFA134a mass ratio is 1:1 -The mass ratio of ethanol / isopropanol-HFA134a is 0.01:2:97.99; in system 11, the mass ratio of ethanol-isopropanol is 1:2, and the mass ratio of fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com