Power tool turret of precision numerical control machine tool

A power turret, precision numerical control technology, applied in metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc., can solve problems such as poor cooling effect, waste of water resources, etc., to improve cooling effect and promote firm installation Sexuality, the effect of promoting the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

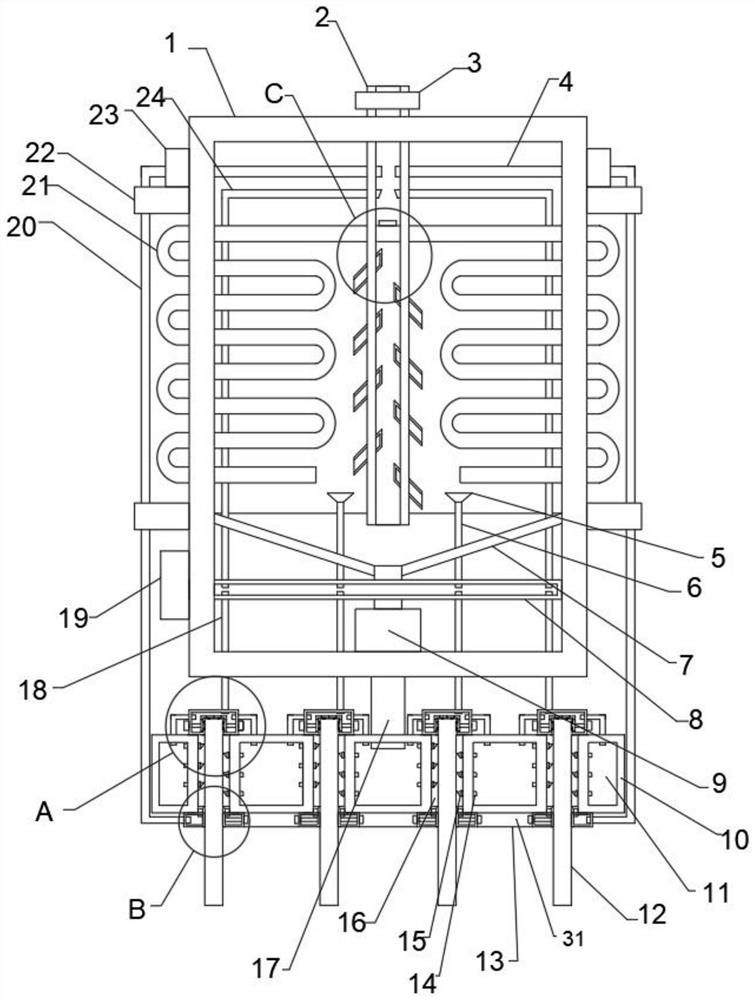

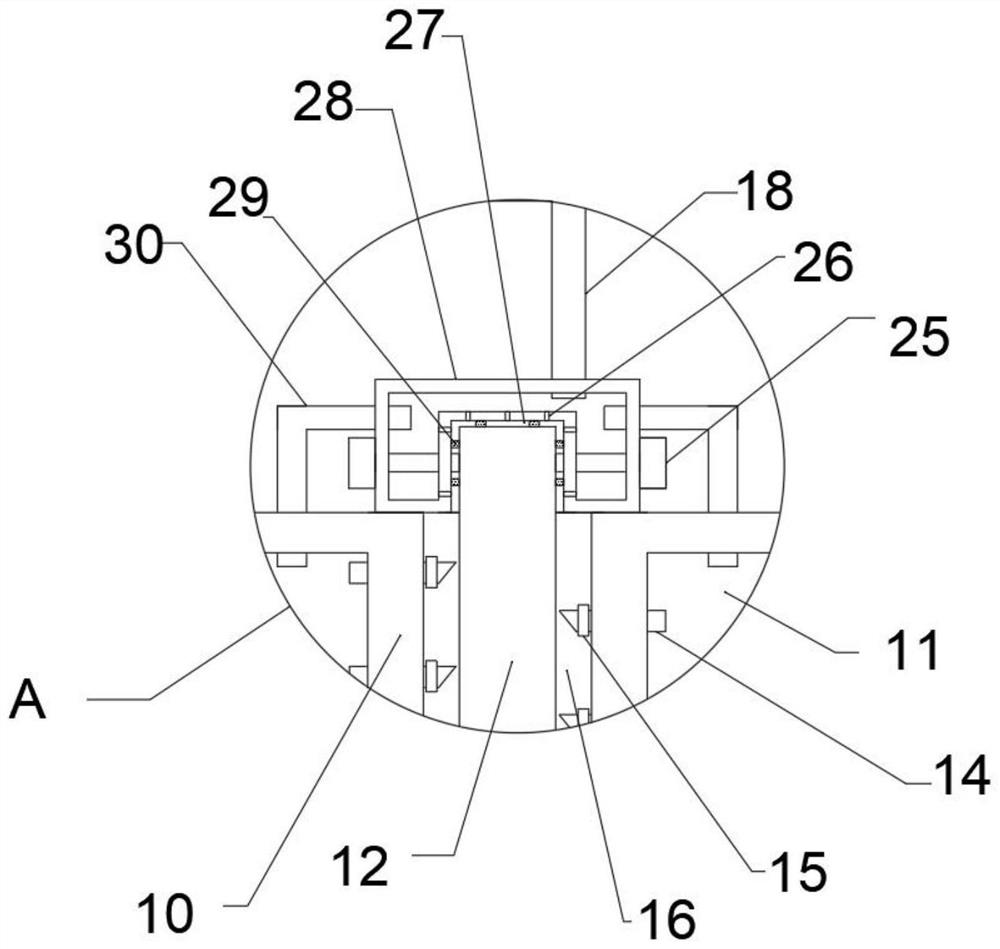

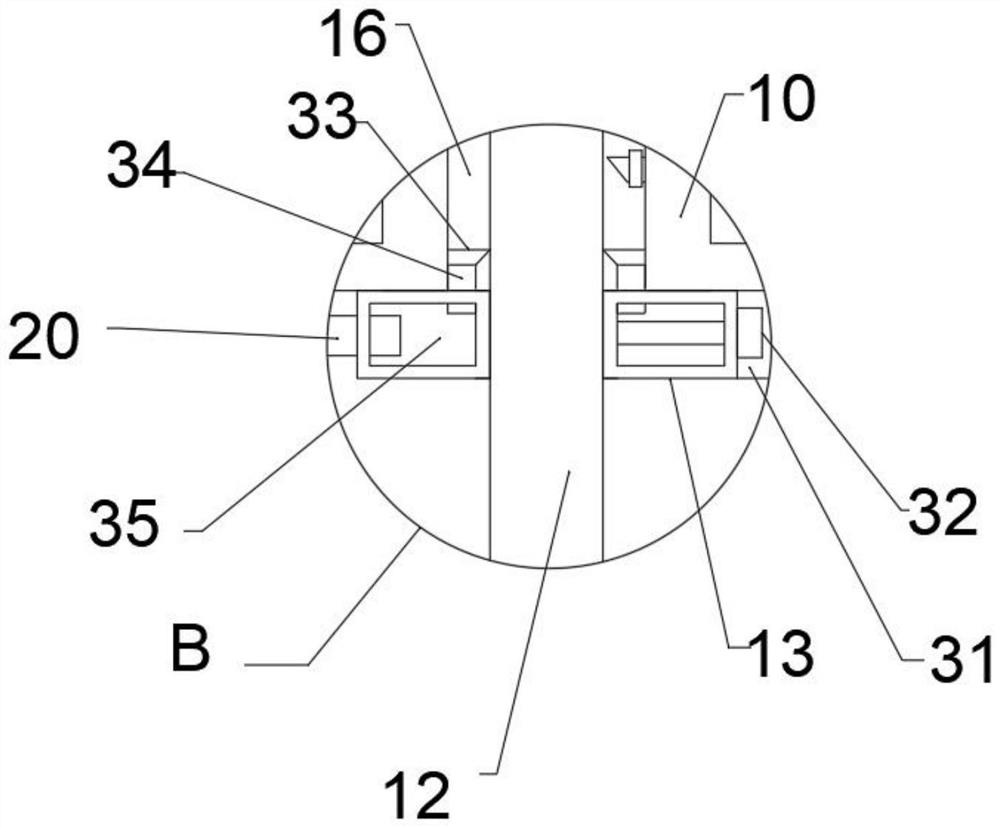

[0031] refer to Figure 1-6 , a precision CNC machine tool turret, comprising a casing 1, the bottom of the casing 1 is provided with a cutter head 10, the cutter head 10 is provided with a plurality of first through grooves 16, the inner wall of the first through groove 16 is provided with a cutter 12, and the top of the cutter 12 is provided A fixing mechanism is provided, both ends of the inner wall of the first through groove 16 are provided with a liquid spray cooling mechanism, a first liquid collecting cavity 11 is opened on the inner wall of the cutter head 10, and a second liquid conduit 17 is fixedly connected to the top of the cutter head 10. The top of the catheter 17 is fixedly connected to the casing 1, the inner wall of the casing 1 is provided with a liquid supply mechanism, the bottom of the cutter head 10 is fixedly connected to the limit plate 13, and both ends of the outer wall of the limit plate 13 are provided with a water circulation mechanism. The secon...

Embodiment 2

[0041] refer to Figure 7 , a precision CNC machine tool turret, the metal tube 37 is close to one end of the liquid inlet pipe 2 with a movable groove 39, the inner wall of the movable groove 39 is rotatably connected with a first rotating rod 40, and the outer wall of the first rotating rod 40 is fixedly connected with a plurality of The rotating plate 41 is arranged in an arc shape and is evenly distributed.

[0042] When in use, by setting the air pump 19 and using the second air duct 8 and the first air duct 6, the airflow can be ejected from the jet hood 5 on the top thereof, and the airflow enters the heat exchange chamber 38 in the metal pipe 37, realizing the opposite flow. For the purpose of heat exchange and cooling treatment of the liquid inside the liquid pipe 2, the first rotating rod 40 in the movable groove 39 at one end of the metal pipe 37 is arranged under the action of the air flow, and the outer wall of the first rotating rod 40 is provided with a pluralit...

Embodiment 3

[0044] refer to Figure 8 , a precision CNC machine tool power turret, one end of the first liquid conduit 4 is provided with a second rotating rod 43, the bottom of the second rotating rod 43 is rotatably connected to the inner wall of the liquid inlet pipe 2, and the outer wall of the second rotating rod 43 is fixedly connected with multiple A spoiler 42 is provided at one end of the twister 42 , and the spoiler 44 is fixedly connected to the outer wall of the second rotating rod 43 .

[0045] When in use, by setting the second rotating rod 43 in the liquid inlet pipe 2, the spoiler 44 on the outer wall can be used to achieve the purpose of rotation under the impact of liquid and airflow, so that the auger 42 on the outer wall can be used to promote the entry of the liquid. The efficiency also further improves the cooling effect of liquid stirring, and finally further improves the cooling effect of the subsequent cutting tools 12 in the cutter head 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com