Closed-loop temperature control variable-position heat source continuous fiber composite material forming equipment

A continuous fiber and composite material technology, which is applied in the field of closed-loop temperature-controlled variable-position heat source continuous fiber composite material forming equipment, can solve the problems of small heating area, low heating temperature, and large volume, and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be pointed out that the following embodiments are intended to facilitate the understanding of the present invention, but do not have any limiting effect on it.

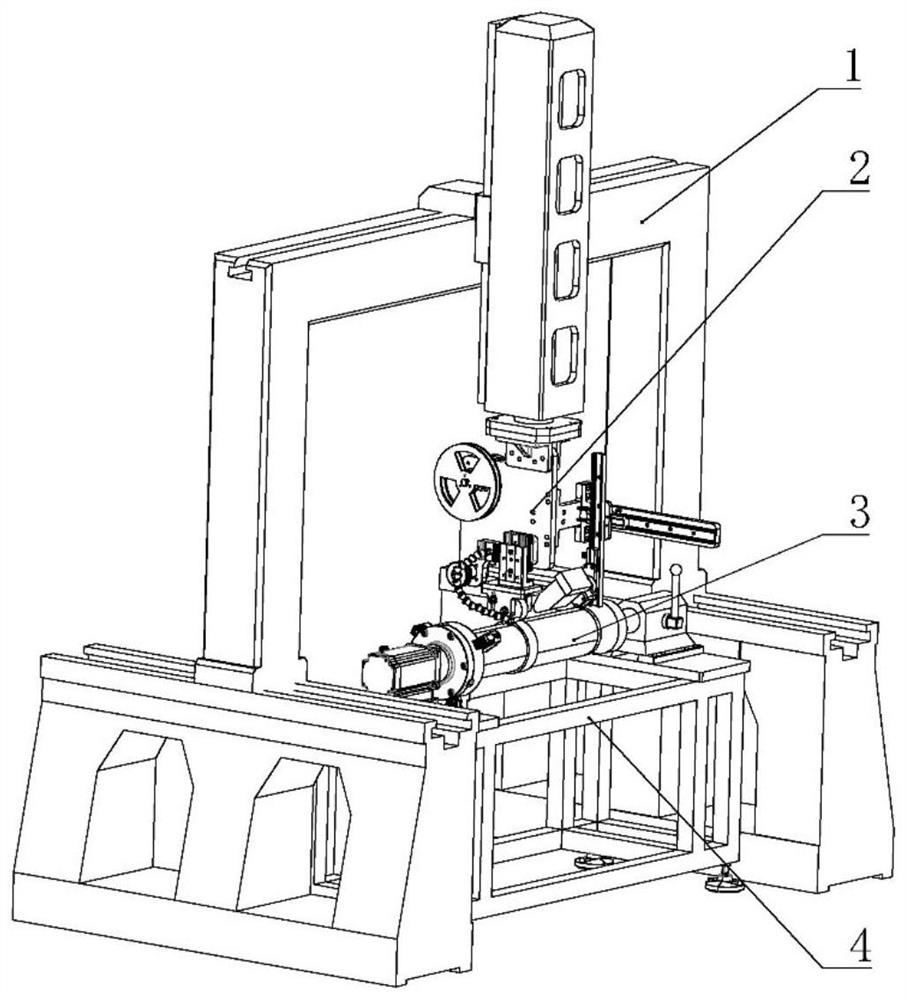

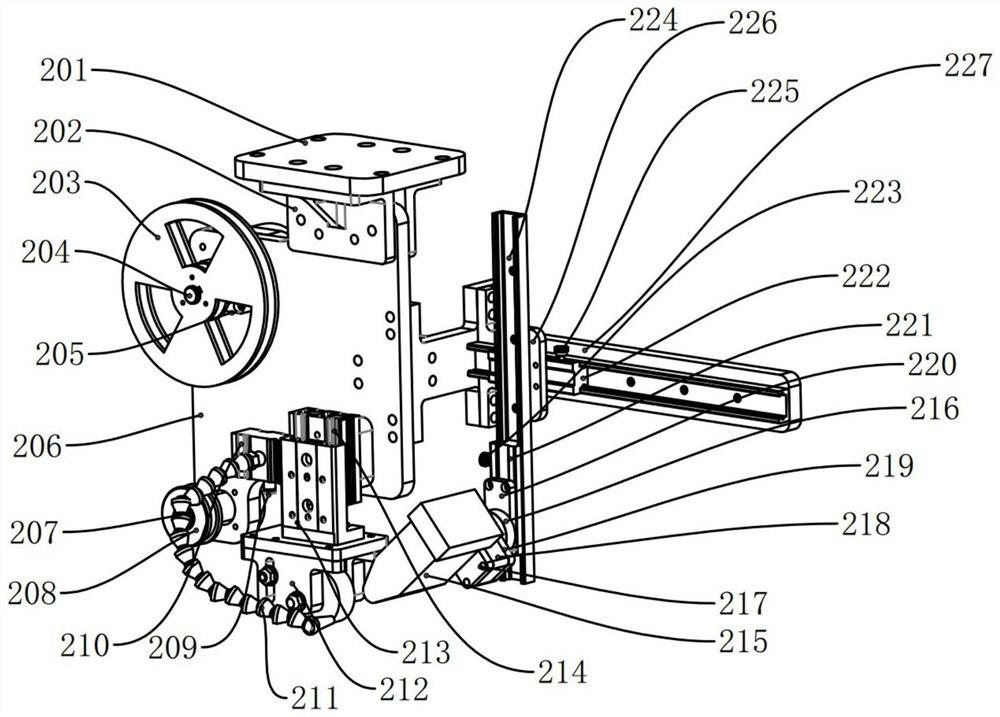

[0038] like figure 1 As shown in the figure, a closed-loop temperature-controlled variable-position heat source continuous fiber composite material molding equipment includes a gantry-type four-axis motion platform 1, an in-situ additive molding equipment based on a pulsed xenon lamp movable heat source 2, and a fiber molding with a temperature detection function. Module 3, the fiber forming module is installed on the desktop 4.

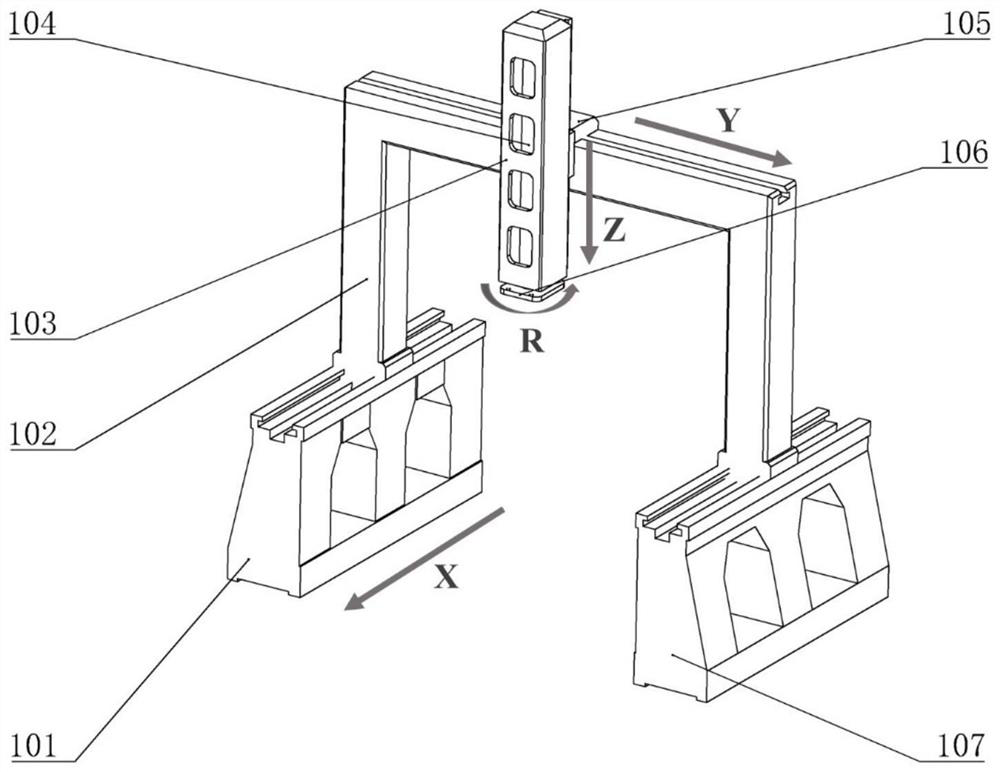

[0039] like figure 2As shown, the gantry type four-axis motion platform 1 includes a gantry column 102 slidably fixed on the first vibration isolation base 101 and the second vibration isolation base 2 107, and the upper end surface of the vibration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com