Automatic and efficient deodorization spraying system for garbage transfer station

A garbage transfer station and spray system technology, applied in the field of deodorization spray system, can solve the problems of low degree of intelligent automation, time-consuming and labor-intensive, etc., and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

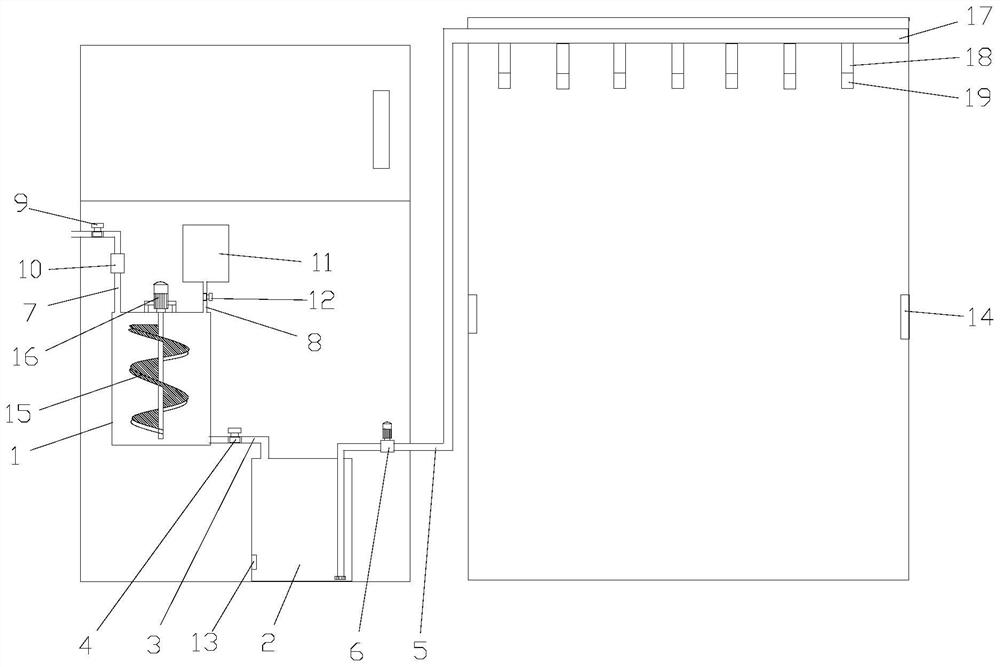

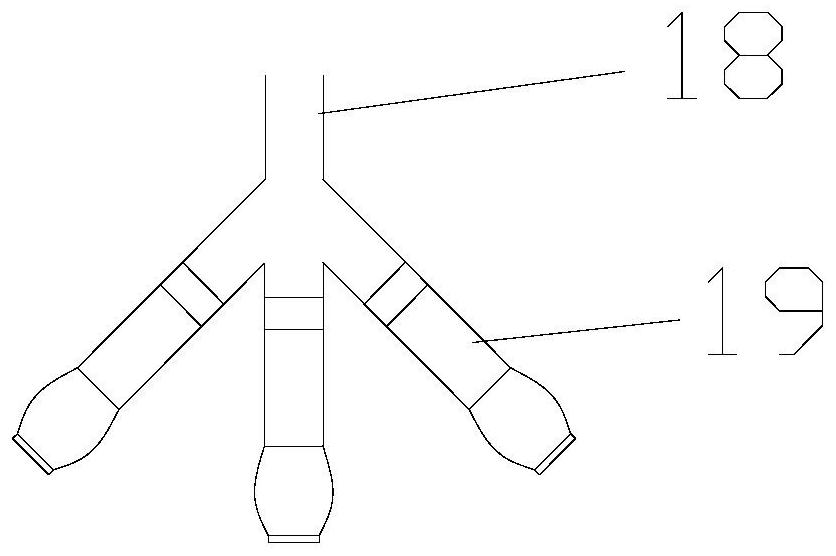

[0015] as Figure 1 and Figure 2 , the present embodiment provides an automatic and efficient deodorization spray system for garbage transfer stations, comprising a liquid dispensing bucket 1, a pumping bucket 2, a first connection pipe 3, a first solenoid valve 4, a second connection pipe 5, a high-pressure pump 6, a third connection pipe 7, a fourth connection pipe 8, a second solenoid valve 9, a heater 10, a reagent barrel 11, a third solenoid valve 12, a level sensor 13, a hydrogen sulfide concentration sensor 14, a stirring paddle 15, a stirring motor 16, a spray discharge pipe 17, a atomized water inlet pipe 18, a fogging nozzle 19;

[0016] Specifically, the present embodiment includes a control station and a spray mechanism, the control station is provided with a liquid distribution bucket 1 and a pumping bucket 2, the bottom of the liquid distribution bucket 1 is connected to the top of the pumping barrel 2 through the first connection pipe 3, the first connection pipe 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com