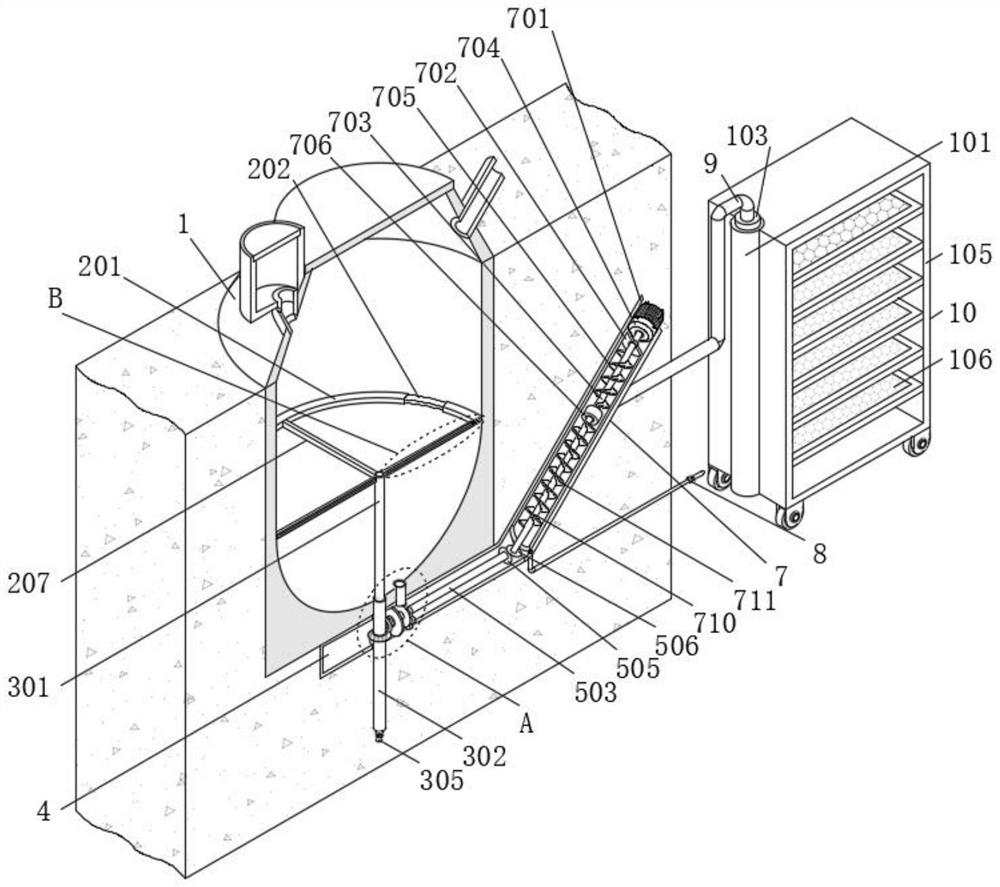

Energy-saving microbial fertilizer fermentation tank and fermentation method thereof

A microbial fertilizer and fermenter technology, which is applied in organic fertilizers, combined biological treatment, organic fertilizer equipment, etc., can solve the problems of agricultural product quality decline, difficulty in cleaning, and low fertility of solid waste, and achieve the effect of increasing production and improving cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

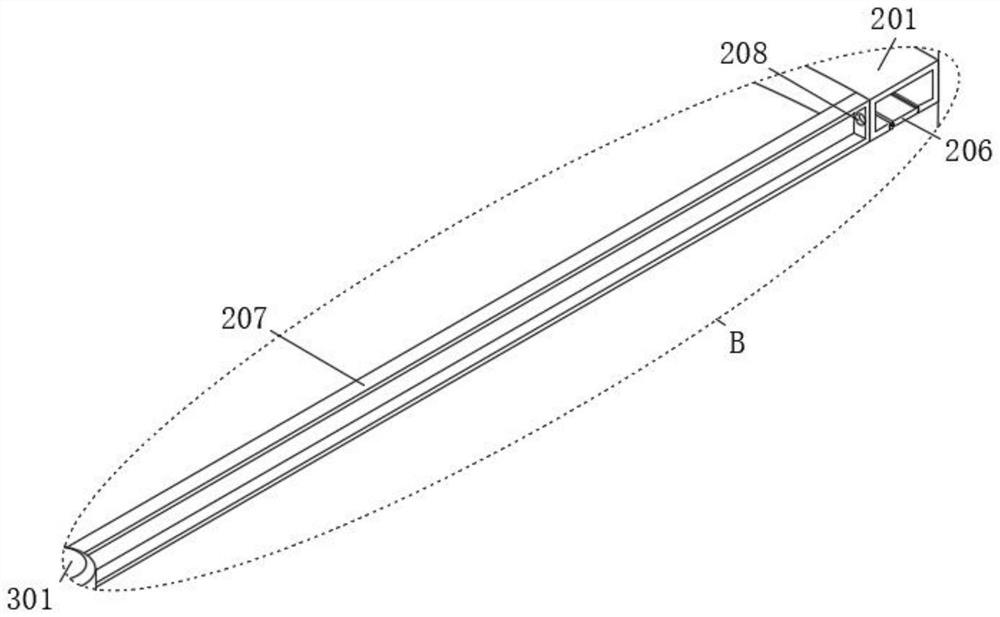

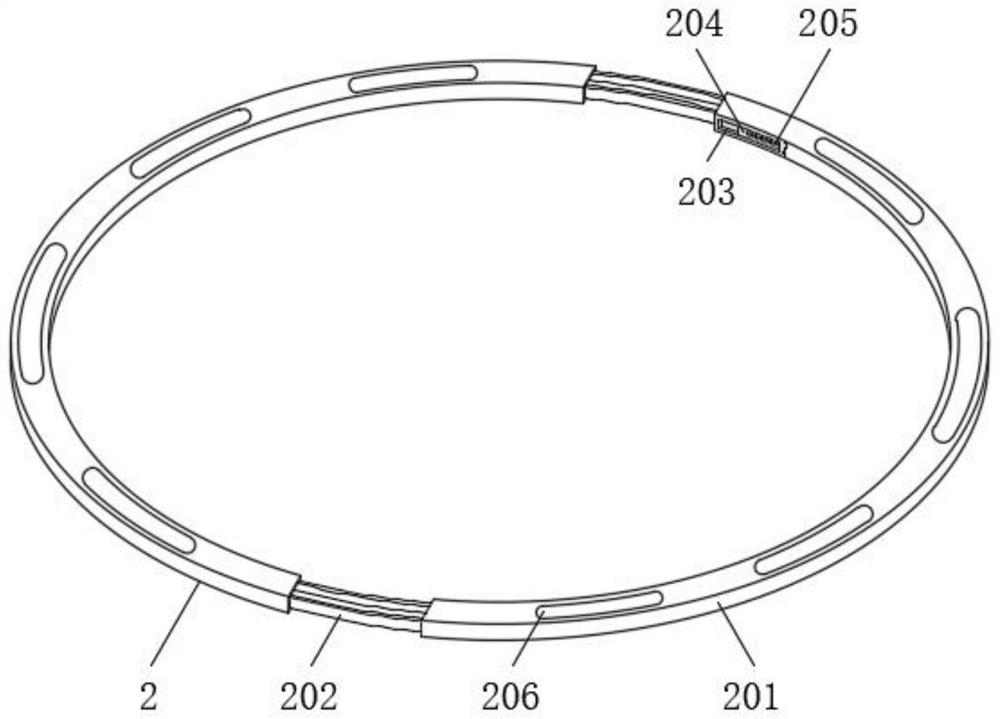

Method used

Image

Examples

Embodiment approach

[0049] Embodiments are specifically: the external thread connection head 103 on the solid discharge pipe 9 is connected to the internal thread connection surface 102, the solid waste can be introduced into the shunt cylinder 101, and the solid waste entering the shunt cylinder 101 will be uniformly flowed into the breeding basket 106 through the tiling port 104 on the shunt cylinder 101, using organic waste to breed earthworms, so that organic waste can be industrialized high-density treatment.

[0050] An energy-saving microbial fertilizer fermentation method, including the following steps:

[0051] Step S1: After the manure and waste straw generated by breeding are put into the interior of the buried fermentation tank 1, the control motor 704 runs to drive the outer piston cylinder 302 to rotate, through the connecting frame 303 to drive the inner layer reciprocating screw 304 rotates inside the middle screw sleeve 301, under the combined effect of torque and thread bite force, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com