Bio-based epoxy compound compatibilized and modified PLA/PBAT composite material and preparation method thereof

A technology of epoxy compounds and composite materials, applied in the directions of bio-packaging, climate sustainability, sustainable manufacturing/processing, etc., can solve the high synthesis cost of block copolymers, the inability of large-scale industrial production of compatibilizers, and the synthesis process Complicated problems, to achieve the effect of improving mechanical properties, high value, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Preparation of polyester elastomer compatibilized PLA / PBAT composites:

[0047] The PLA and PBAT pellets were dried in a vacuum oven at 60°C for 24 hours before use. Dried PLA and PBAT were mixed by Haake Remix (Remix 600p, Thermo Scientific Co., Germany) in a mass ratio of 70 / 30 at 200°C at 60 rpm and 0 phr, 0.5 phr for 10 minutes. During mixing, 1 phr, 3 phr, 5 phr, 7 phr, 9 phr of ESO were introduced into the mixture. The samples were injection-molded at 190 °C by an experimental micro-injection molding machine (WZS10D, Shanghai Xinshuo Precision Machinery Co., Ltd.), and prepared as samples for use.

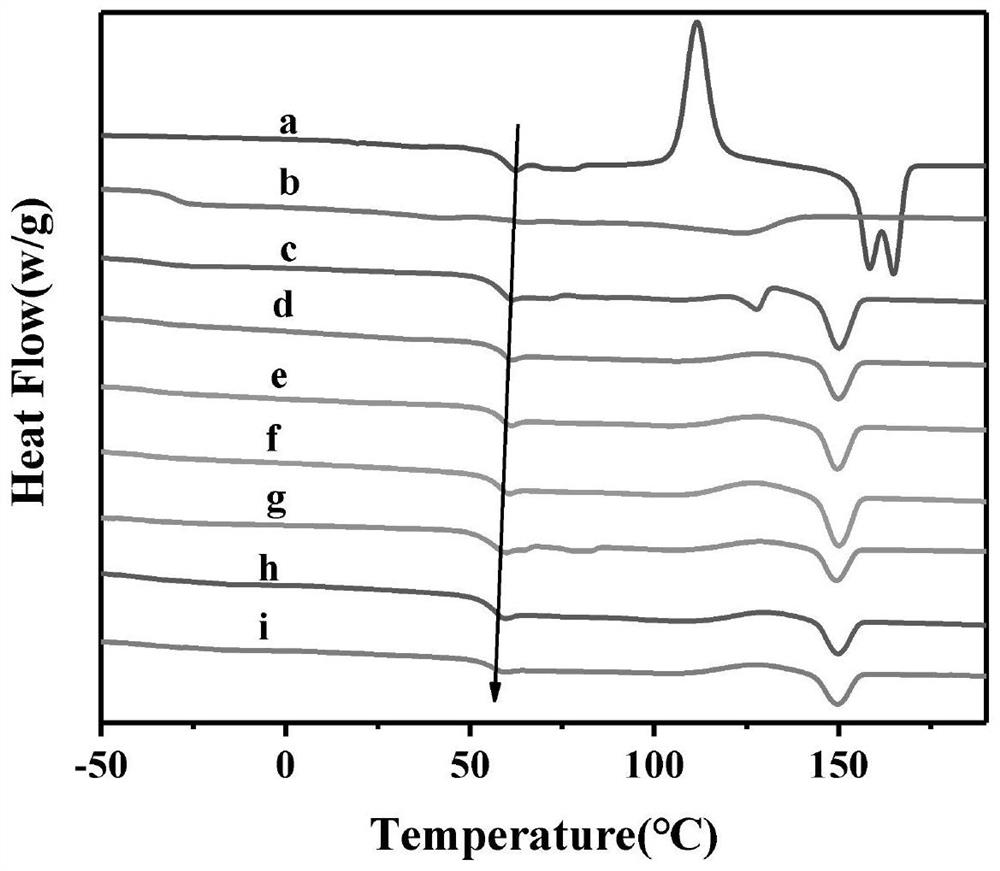

[0048] Table 1. Thermodynamic characterization data of PLA, PBAT and PLA / PBAT composites before and after compatibilization

[0049]

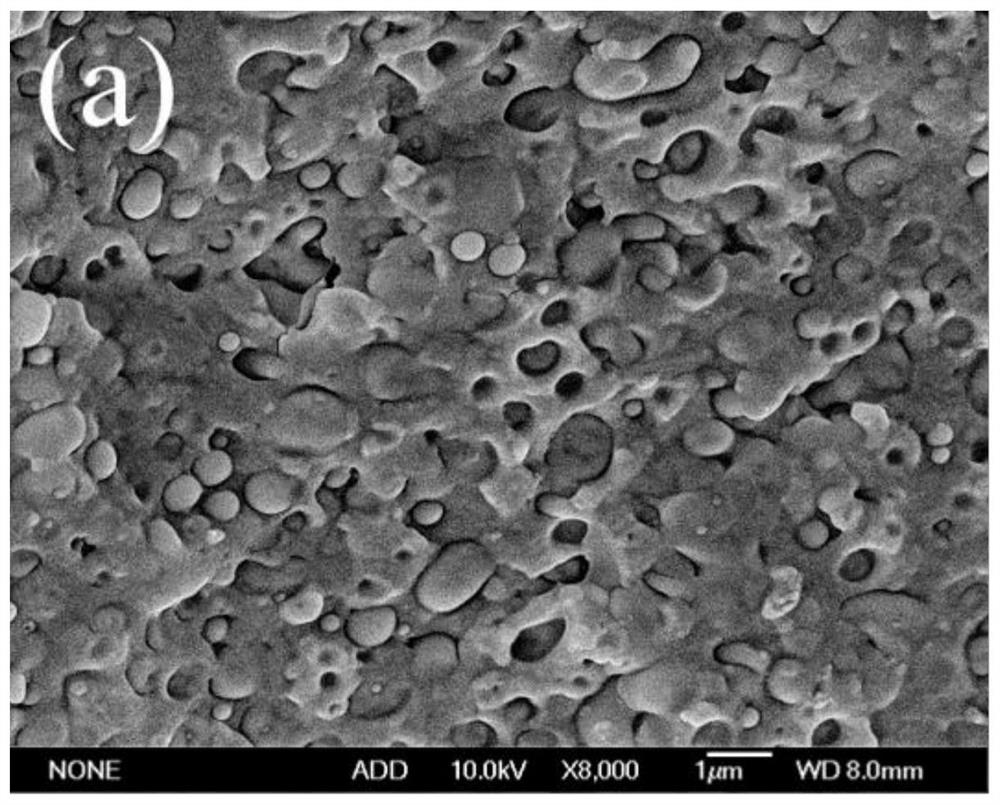

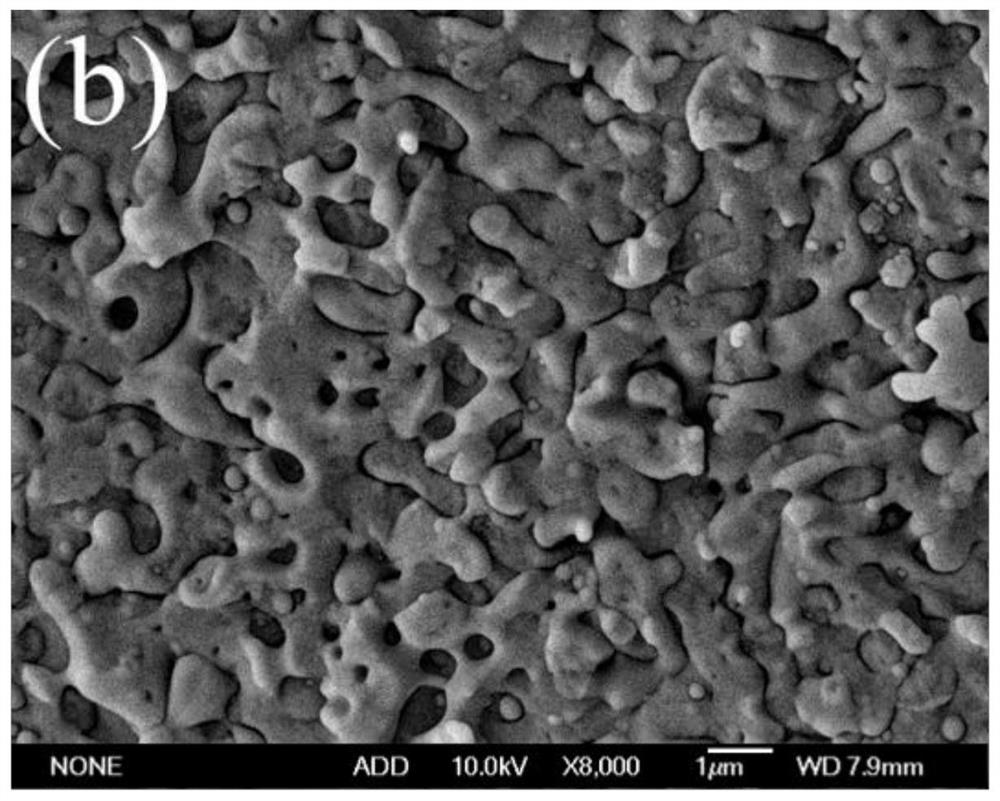

[0050] The thermodynamic performance test results of PLA, PBAT and PLA / PBAT composites before and after compatibilization modification are listed in Table 1. It can be seen that when ESO is added, the Tg (DSC) of PLA decreases sign...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com