Truss structure design method based on large-space multi-story building

A truss structure, multi-storey building technology, applied in the direction of truss structure, building structure, construction, etc., can solve the problems of building economic impact, can not meet the large-scale cold chain transport vehicles and other problems, achieve high bearing capacity and short construction period , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

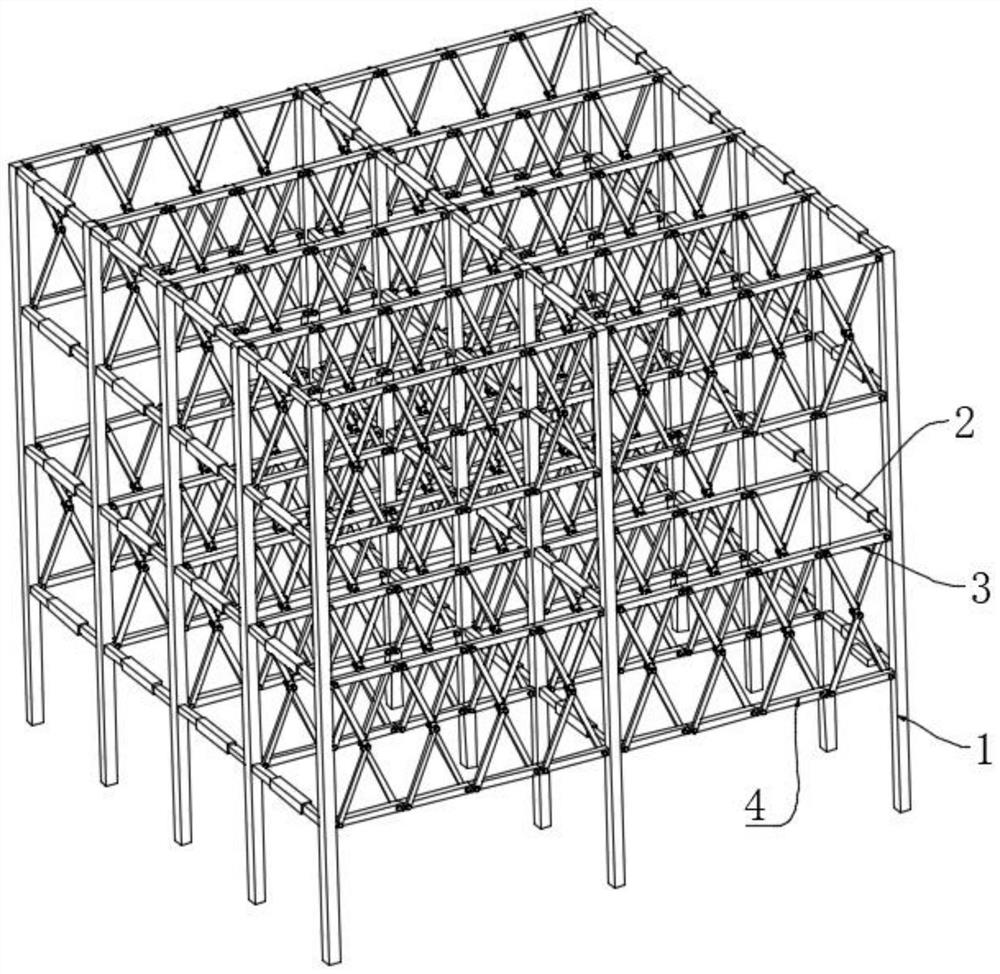

[0042] as attached Figure 1-3 A truss structure design method based on a large-space multi-storey building shown, including multiple groups of columns 1 arranged side by side, the column 1 is used as the column structure of the overall factory building, and the number of each group of columns 1 is set to 4. Connecting beams 2 are installed between two adjacent columns 1 in the group of columns 1. The connecting beams 2 are arranged in an array along the direction of the column 1 with four floors. The connecting beams 2 of different heights represent different floors. The number of vertical columns in each row is reduced, and the expansion joints in the prior art are cancelled, and several truss structures are distributed in an array along the side wall of the column 1 to form an interlayer truss structure system;

[0043] The interlayer truss structure system includes several first support frame structures arranged linearly, the first support frame structure on the same horiz...

Embodiment 2

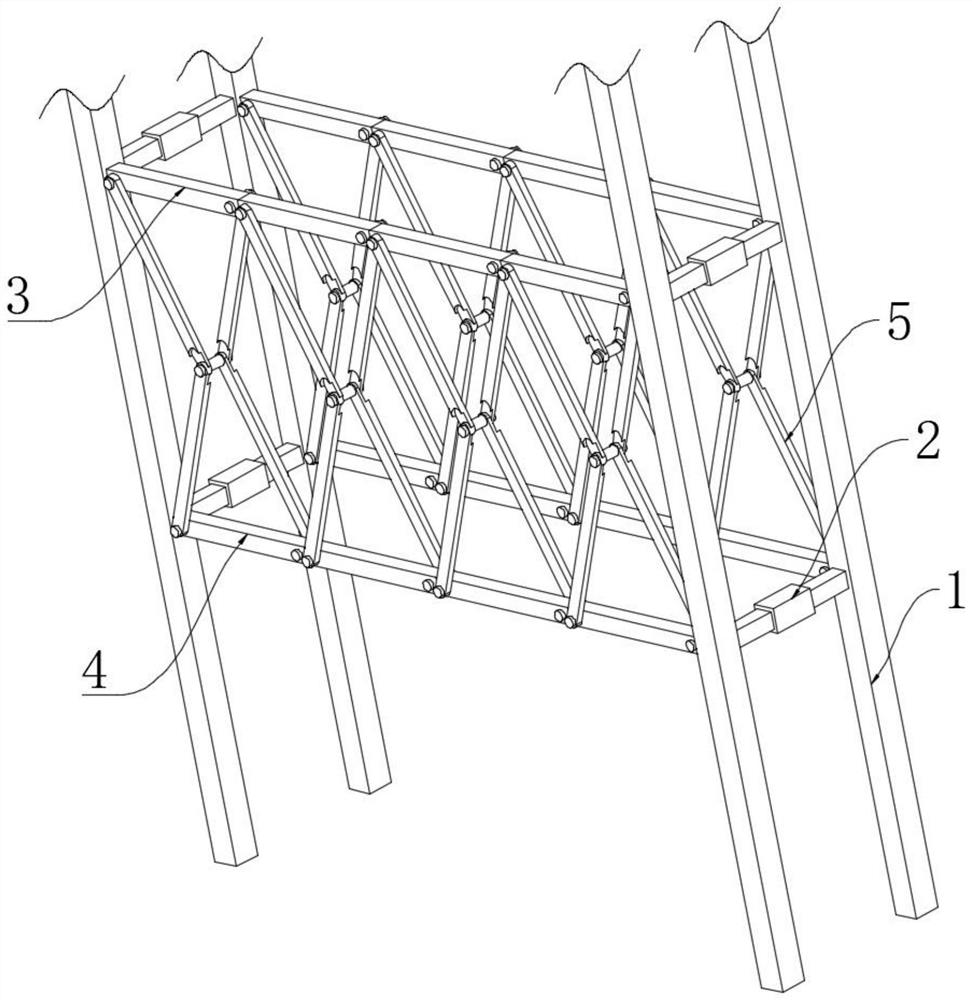

[0045] This embodiment provides a truss structure design method based on a large-space multi-storey building, as shown in the attached Figure 4-7As shown, there are multiple groups of uprights 1 arranged side by side, and the uprights 1 are used as the upright structure of the whole factory building, the number of each group of uprights 1 is set to 5, and there are installed between two adjacent uprights 1 in each group of uprights 1. Coupling beam 2. Coupling beams 2 of different heights represent different floors. Coupling beams 2 are arrayed along the direction of column 1 with four floors. Coupling beams 2 of different heights represent different floors. Several truss structures are distributed in an array on the side wall to form a superimposed truss structure system;

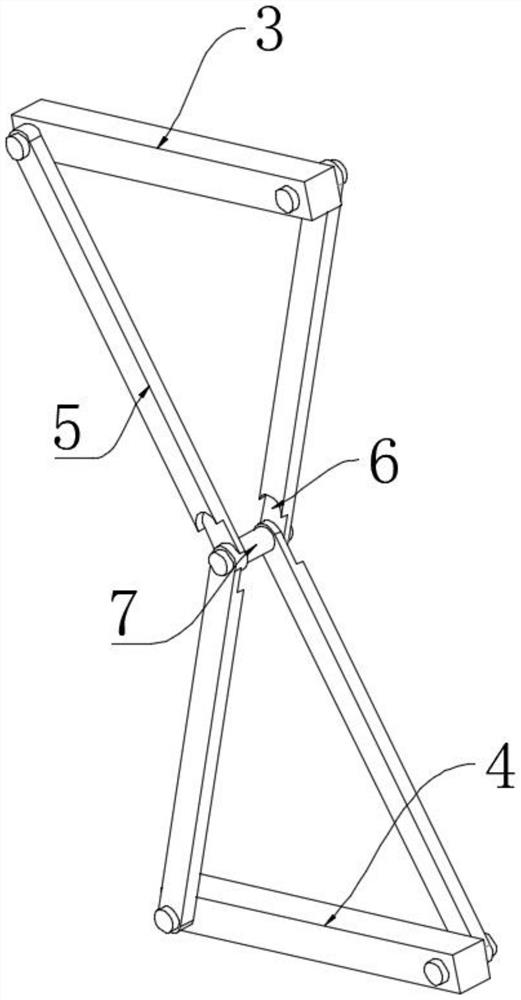

[0046] The superimposed truss structure system includes several second support frames distributed in an array along the surface of the column 1. The second support frame includes an upper chord 8, a lower...

Embodiment 3

[0049] This embodiment provides a truss structure design method based on a large-space multi-storey building. Building B of a new material intelligent manufacturing industrial park in a county is a 4-story factory building with a total length of 120.3 meters and a total width of 50 meters; the first floor The height is 6.3 meters, the rest of the floors are 5.1 meters high, and the total building height is 21.6 meters. The design life of the main structure is 50 years, the seismic fortification category of the building is Class C, the seismic fortification intensity is 6 degrees, the design basic seismic acceleration is 0.05g, the design earthquake is grouped into the first group, and the seismic level is four. The main structure adopts a multi-truss structure system arranged in the longitudinal direction (that is, the X direction). The horizontal (ie Y direction) truss distance is 10 meters, and the total height of the structure is 21.6 meters. The layout of the space struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com