Detector optical machine assembly integrated with photosensitive surface conjugate diaphragm

A photoelectric detector and detector technology, which is applied in the direction of instruments, measuring devices, electromagnetic wave re-radiation, etc., can solve the complicated and complicated alignment of multi-element laser emission, the complicated and cumbersome adjustment process of optical axis, and the reduction of signal-to-noise ratio of received signals, etc. problems, to achieve the effect of strong anti-stray light and anti-electromagnetic interference, simple and easy to implement, and high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]To make the object, content and advantages of the present invention more clear, the following in conjunction with the accompanying drawings and embodiments, the specific embodiments of the present invention will be described in further detail.

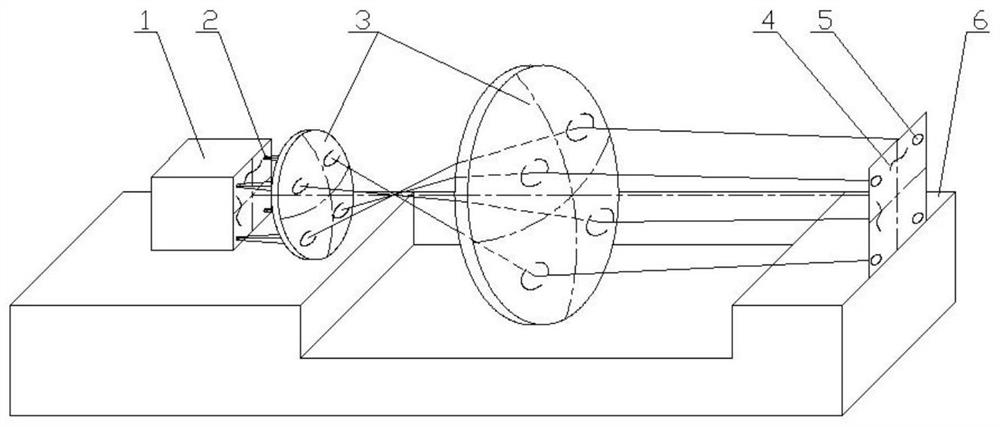

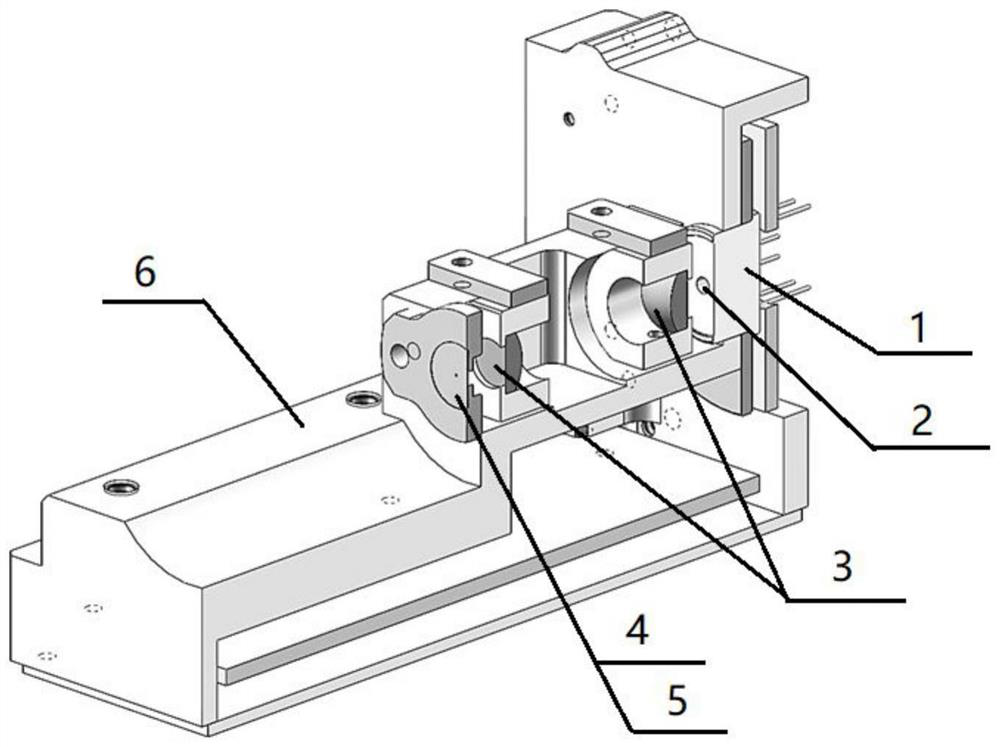

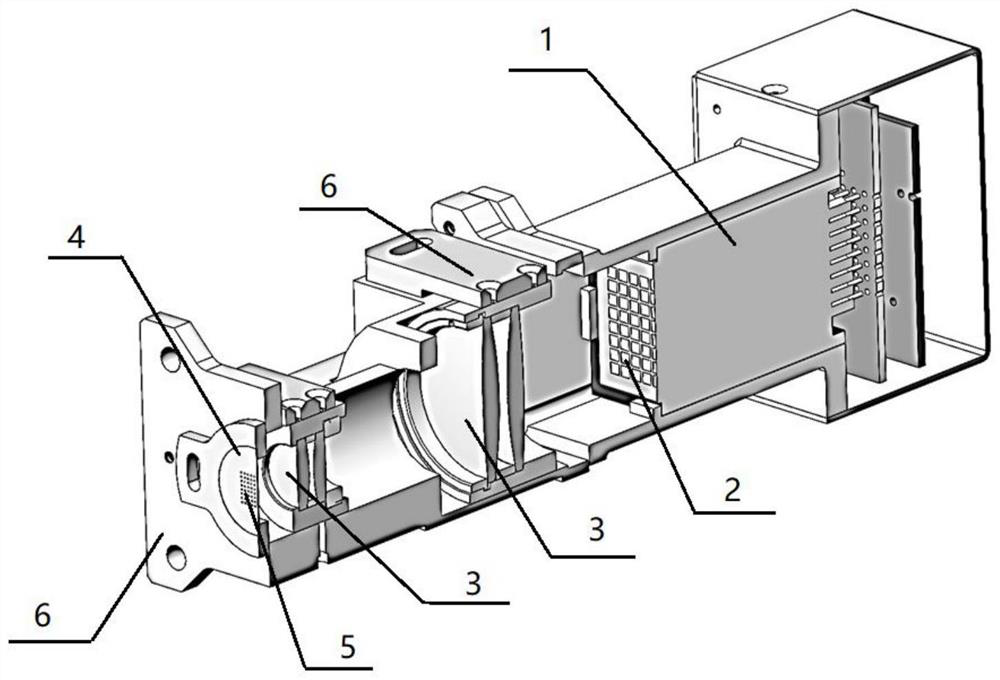

[0021] Reference Figures 1 through 3 As shown, the present embodiment integrates a photosensitive surface conjugated diaphragm detector optical machine assembly comprising a front-to-back coaxial arrangement of the diaphragm 4, projection optical system 3, detector 1, the photosensitive surface 2 on the detector 1 and the diaphragm 4 aperture 5, respectively, in the projection optical system 3 of the object and image surface, and according to the imaging relationship one-to-one correspondence.

[0022] Among them, the diaphragm 4, projection optical system 3, detector 1 are arranged on the installation structure 6, and the installation structure 6 is integrated and installed, and only the diaphragm hole 5 is open to the outside, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com