Compaction equipment for filling negative electrode of lithium battery and compaction method of compaction equipment

A lithium battery and negative electrode technology, which is applied to the compaction equipment for lithium battery negative electrode filling and its compaction field, can solve the problems of inconvenient crucible pressing and forming, and achieve compact overall structure design, convenient and quick demoulding treatment, and convenient and quick pressing and forming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

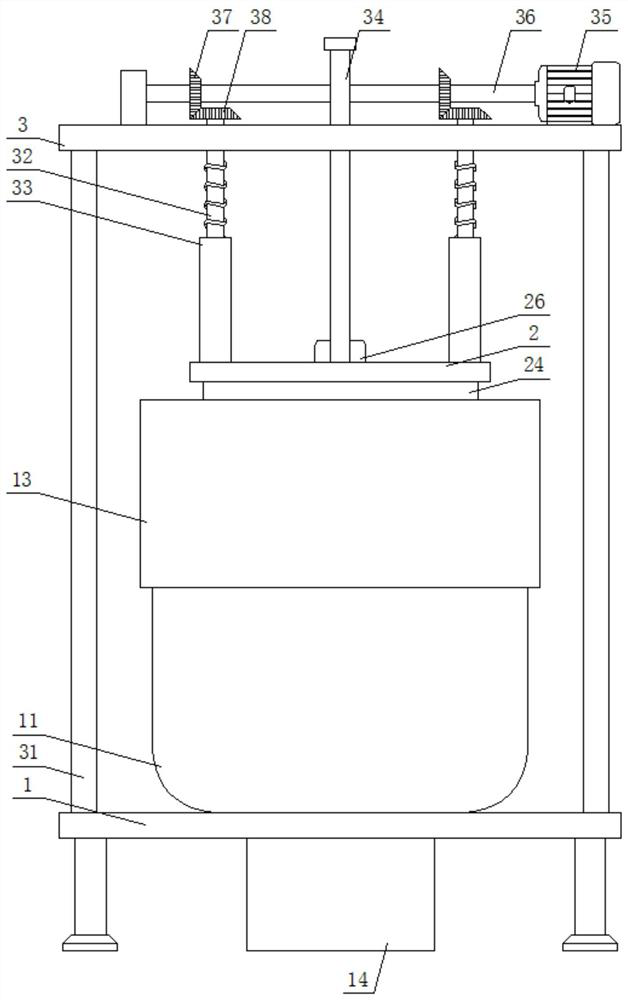

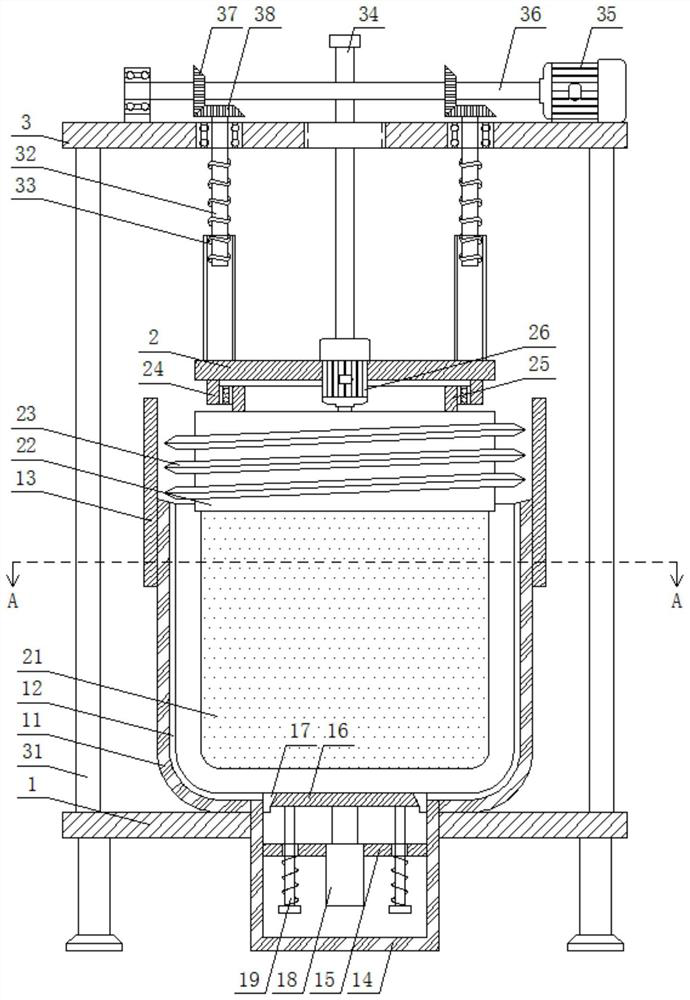

[0034] Embodiment 1: In order to achieve the purpose of rapid compression molding of a crucible made of a lithium battery negative electrode material, this embodiment provides a compaction device for filling a lithium battery negative electrode, see Figure 1-5 Specifically, it includes a bottom plate 1, the bottom plate 1 is a rectangular plate placed horizontally and horizontally, an outer mold cylinder 11 is provided in the middle of the top surface of the bottom plate 1, and the top of the outer mold cylinder 11 is sleeved with a concentric fixed sleeve 13, the bottom plate The middle of the bottom surface of 1 is provided with a circular through hole, and the inside of the circular through hole is provided with a demolding cylinder 14 which is fixed through and connected. The bottom surface is flush, and the demolding cylinder 14 is provided with demoulding components;

[0035] A lift plate 2 is arranged above the sleeve 13, and a top plate 3 placed horizontally is arrang...

Embodiment 2

[0040] Embodiment 2: In Embodiment 1, there is also the problem that it is inconvenient to quickly demold after the crucible is press-molded. Therefore, on the basis of Embodiment 1, this embodiment also includes:

[0041] In the specific implementation process, such as figure 2 and Figure 4 As shown, the demoulding assembly includes a conical disc 16 and an electric push cylinder 18. The inner top port of the demolding cylinder 14 is provided with a conical disc 16, and the outer side of the conical disc 16 is sleeved with a concentrically fixed wear ring 17 The outer side of the wear-resistant ring 17 is slidably connected to the inner wall of the demoulding cylinder 14. The inner middle of the demoulding cylinder 14 is provided with a concentric fixed plate 15, and the middle of the fixed plate 15 is installed with an electric push cylinder 18 whose output end faces upwards. , the model of the electric push cylinder 18 is DSDG80, and the end of the electric push rod of t...

Embodiment 3

[0043] Example 3: see Image 6 , Concrete, working principle of the present invention and operation method are as follows:

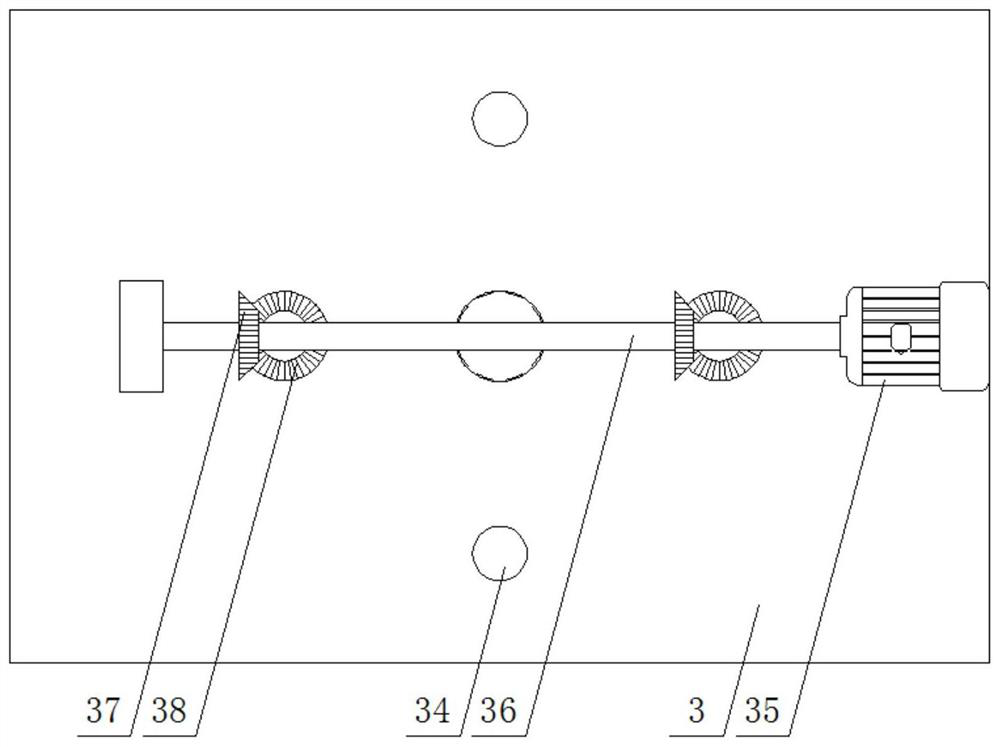

[0044] Step 1, start the first motor 35, the motor shaft of the first motor 35 drives the horizontal shaft 36 to rotate along the positioning bearing, the horizontal shaft 36 synchronously drives a pair of driving bevel gears 37 to rotate, meshing drives the driven bevel gear 38 and the wire The rod 32 rotates along the fixed bearing, and the screw action of the screw 32 and the threaded barrel 33 drives the lifting plate 2 and the hollow mold 21 to slowly descend, and drives the T-shaped limit rod 34 to slide along the limit hole, so that the hollow mold 21 descends into the outer mold cylinder 11;

[0045] Step 2, start the second motor 26, the motor shaft of the second motor 26 drives the hollow die 21 and the inner ring 25 to rotate along the outer ring 24, synchronously drives the inner cylinder 22 and the threaded convex ring 23 to rotate, and sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com