Burning-off type autoclaved brick treatment device

A processing device and technology of autoclaved bricks, which are applied in forming press heads, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of inaccurate control of manual strength, continuous operation, affecting the aesthetics and practicability of autoclaved bricks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

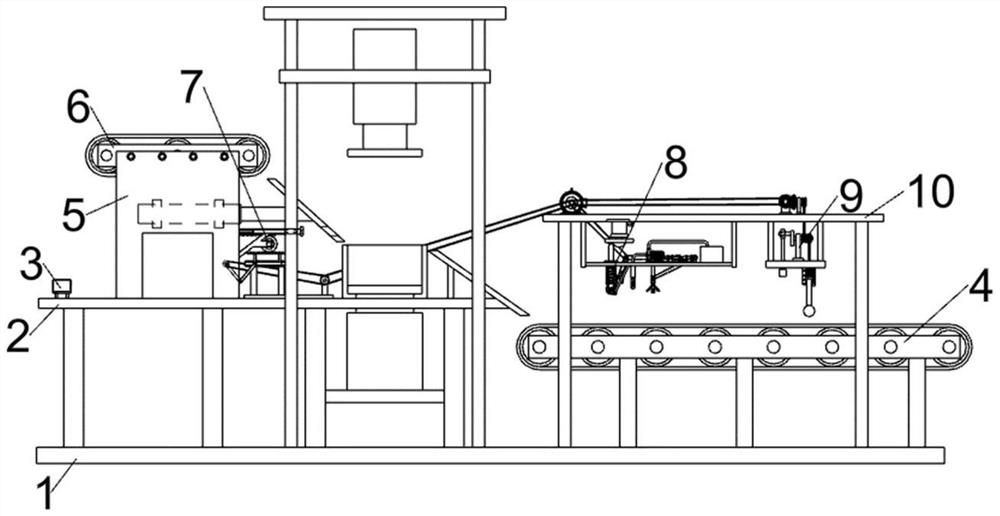

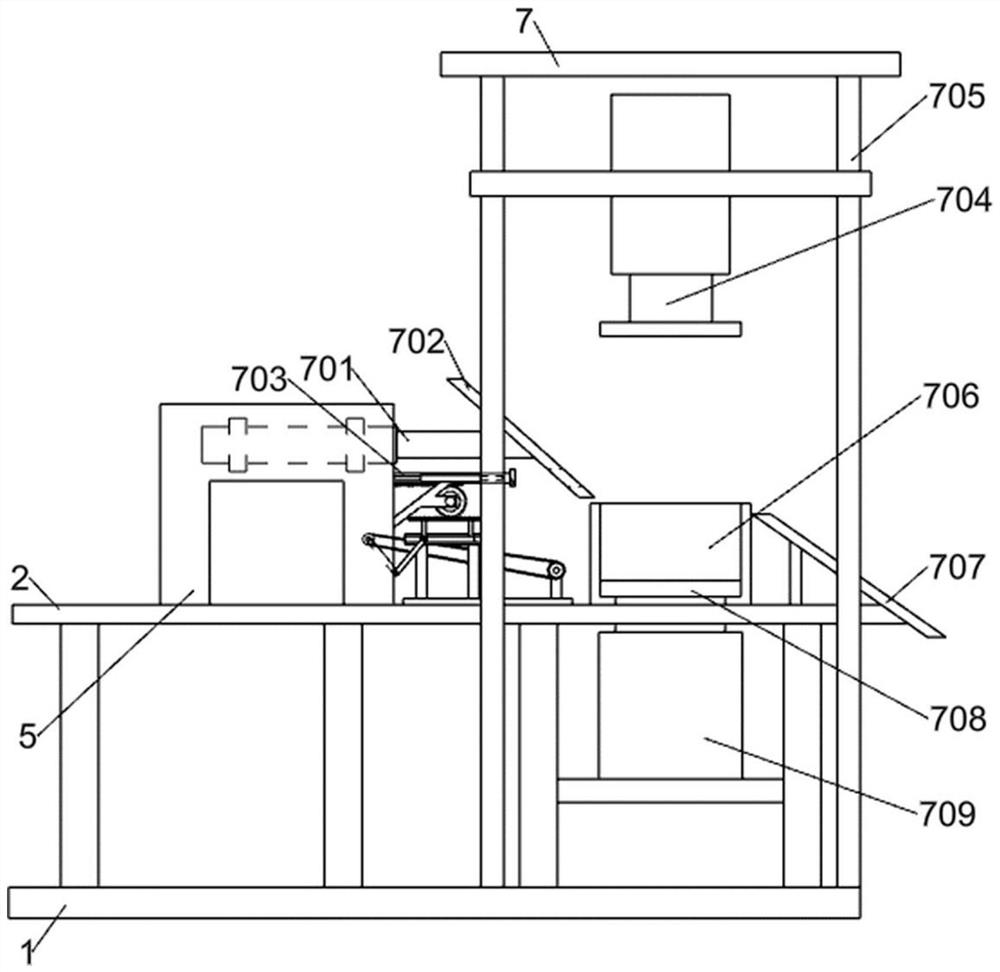

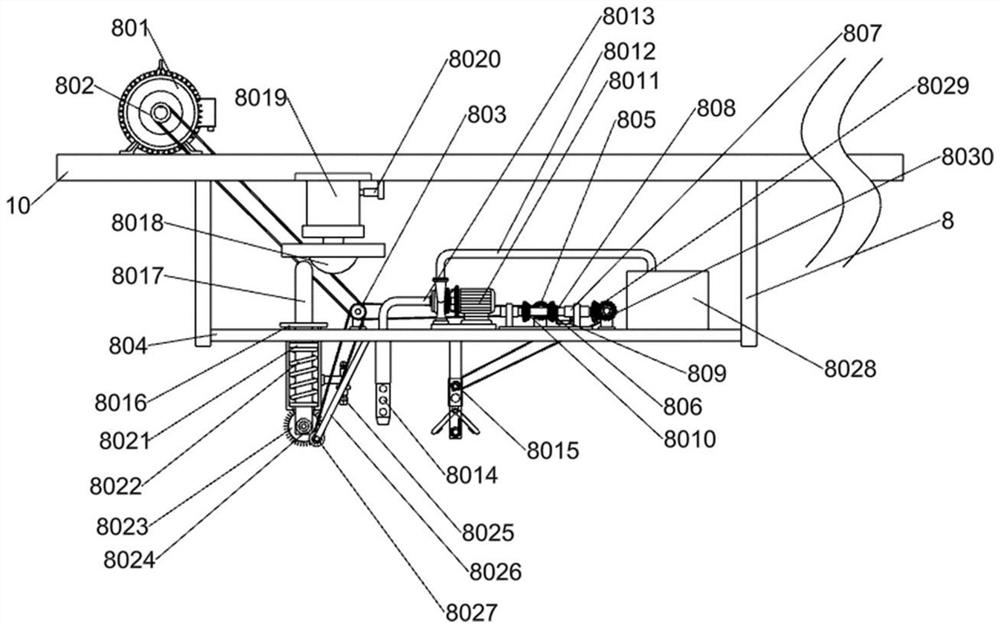

[0029] A burnt type autoclaved brick processing device, such as Figure 1-7 As shown, it includes a machine tool connection base plate 1, an elevated workbench 2, an operation control panel 3, a first conveyor belt 4, an installation platform 5, a second conveyor belt 6, a pressing mechanism 7, a brick body cleaning mechanism 8, and a strength detection mechanism 9 and install the top plate 10; the top of the machine tool connection bottom plate 1 is welded with the elevated workbench 2; the top of the machine tool connection bottom plate 1 is connected with the first conveyor belt 4; the top of the machine tool connection bottom plate 1 is connected with the pressing forming mechanism 7; the top of the machine tool connection bottom plate 1 It is connected with the installation top plate 10; the press molding mechanism 7 is connected with the elevated workbench 2; the upper part of the elevated workbench 2 is connected with the operation control panel 3 and the installation pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com