Machine-made die for making combined cavity member

A technology of mechanism and mould, which is applied in the field of machine-made molds for concrete components, can solve the problems of large mold site occupation, high mold cost, and high speed, and achieve the effects of reducing production time, improving production efficiency, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

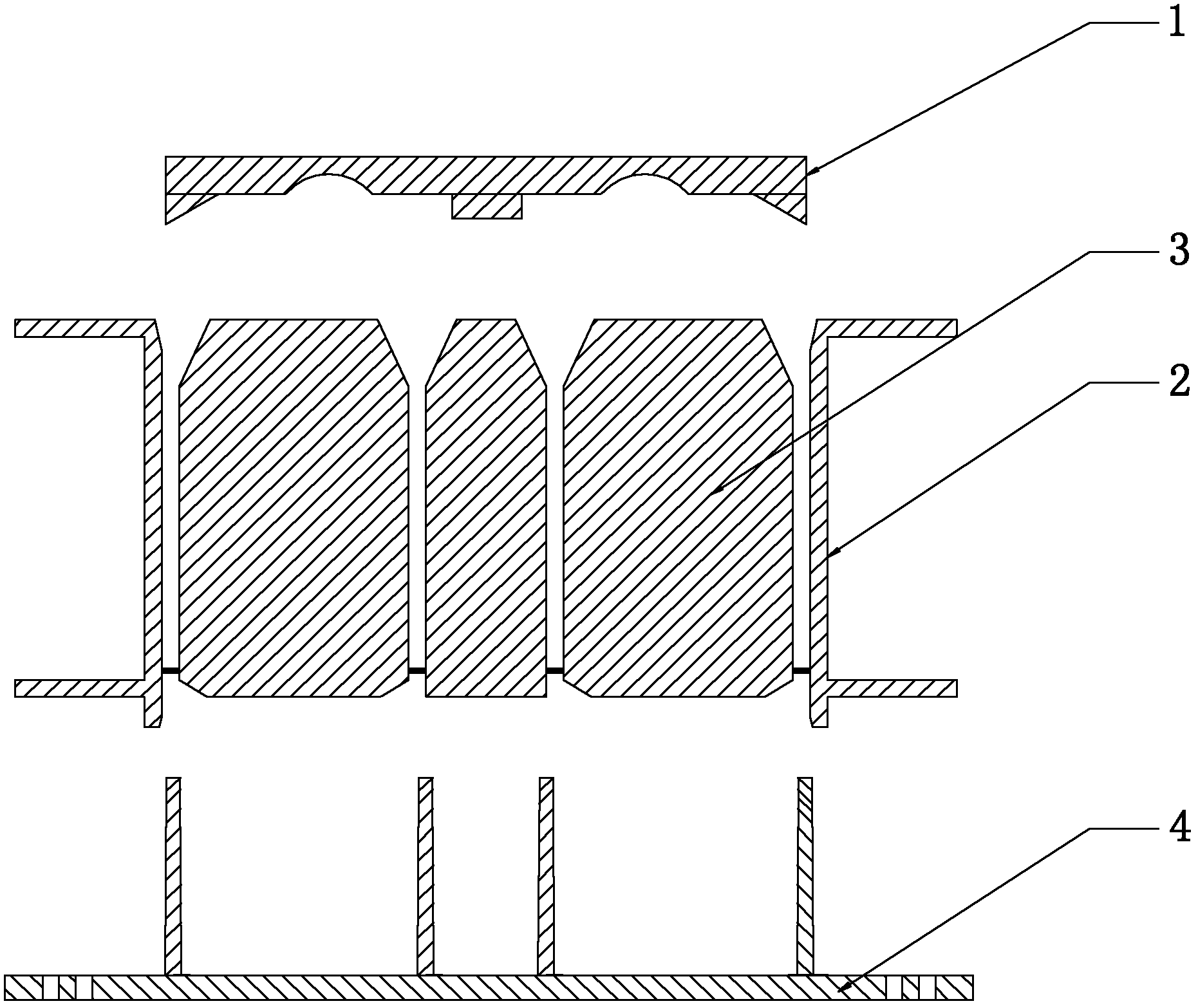

[0024] The technical solution of the present invention is a mold that uses a machine to make a composite cavity member, with figure 1 It is a schematic diagram of the mold structure in the technical solution of the present invention, as figure 1 As shown, the mold subsystem includes a top plate 1, an outer mold frame 2, an inner mold core 3, an opening pressure ring 4, and a mold core 15 for forming holes. The following is a detailed description and analysis of the various components of the mold subsystem in conjunction with the subsequent drawings:

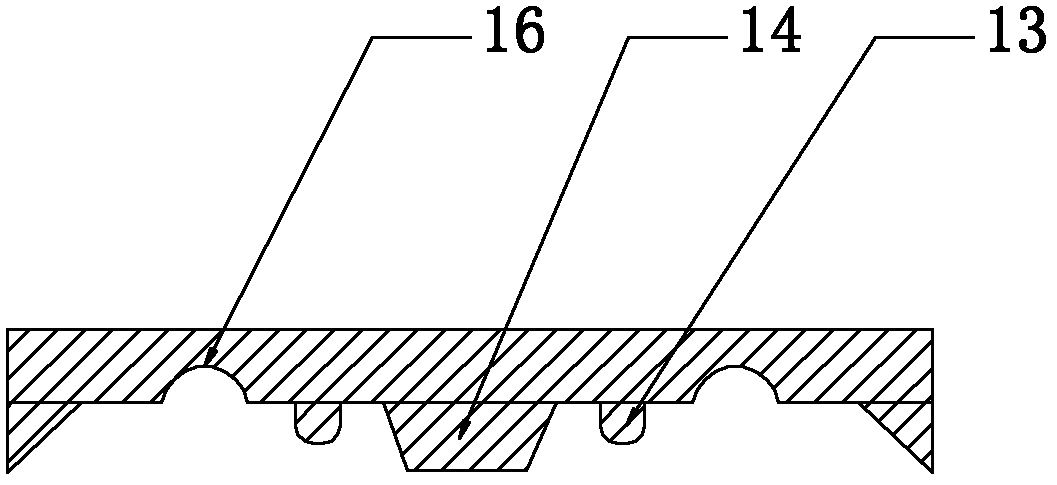

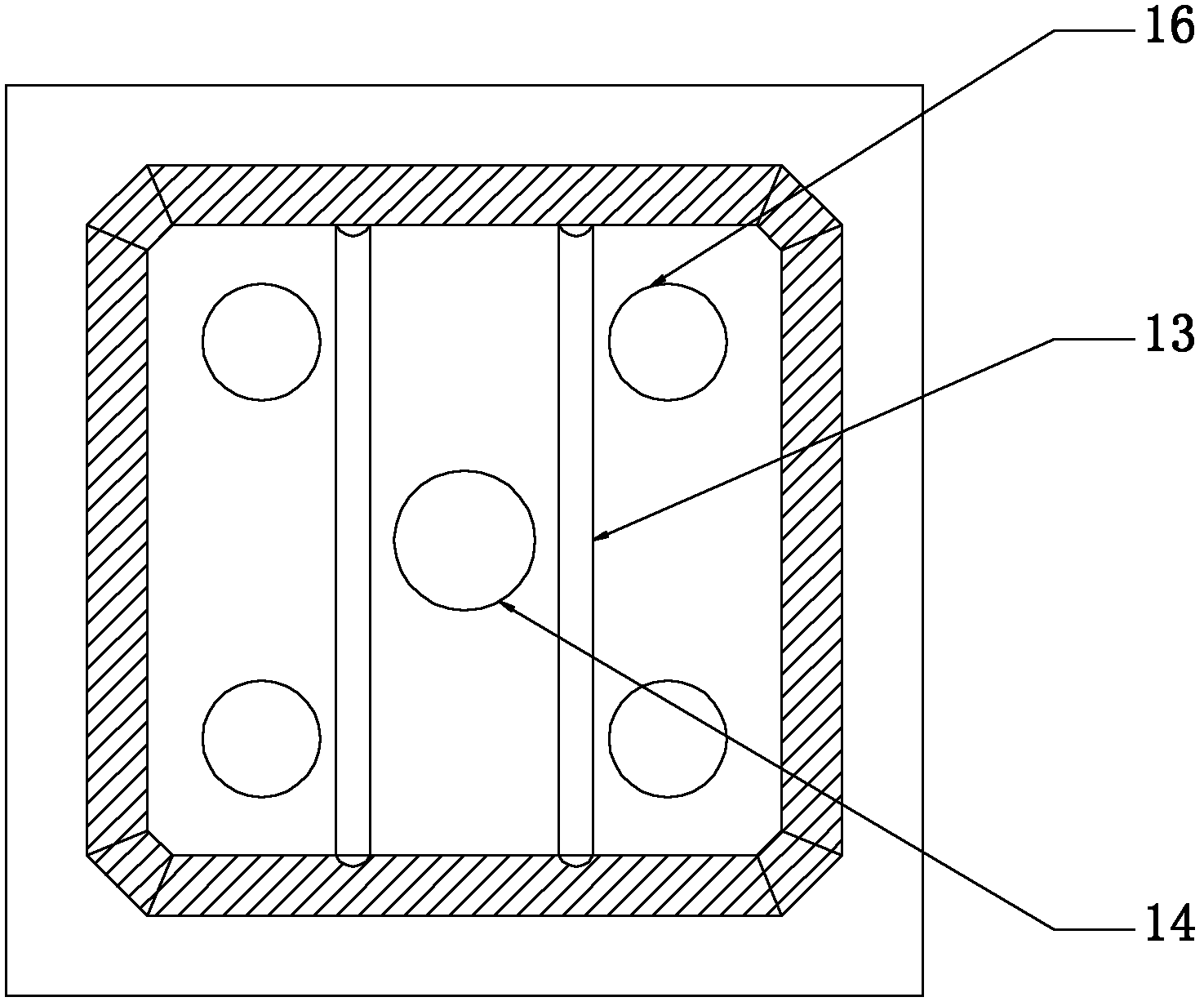

[0025] Fig. 2 is a schematic structural diagram of the top formwork, wherein Fig. 2(a) is a cross-sectional view of the top formwork 1, and Fig. 2(b) is a top view of the top formwork 1 turned upside down. As shown in Figure 2 (a), a hole-forming mold base 14 is provided on the inner surface of the top template 1, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com