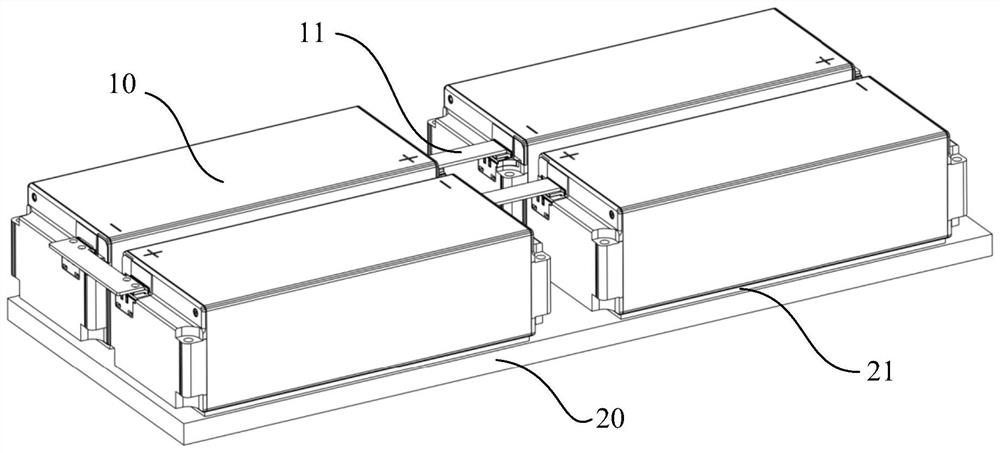

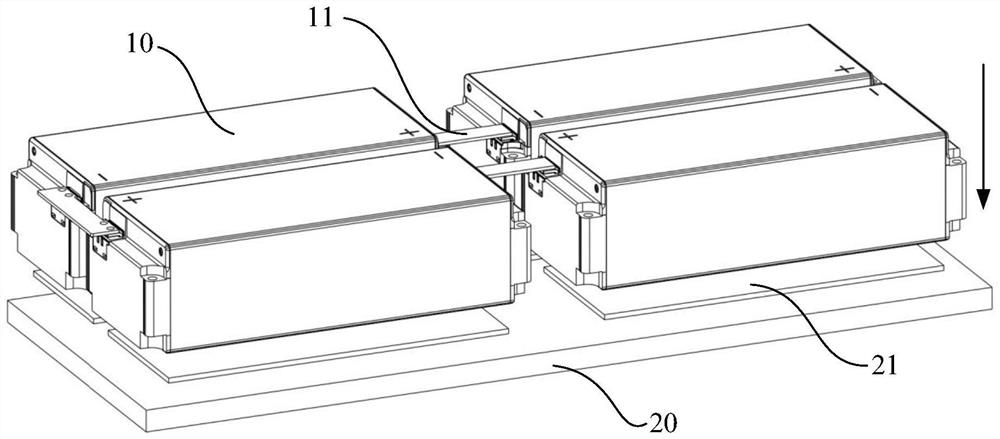

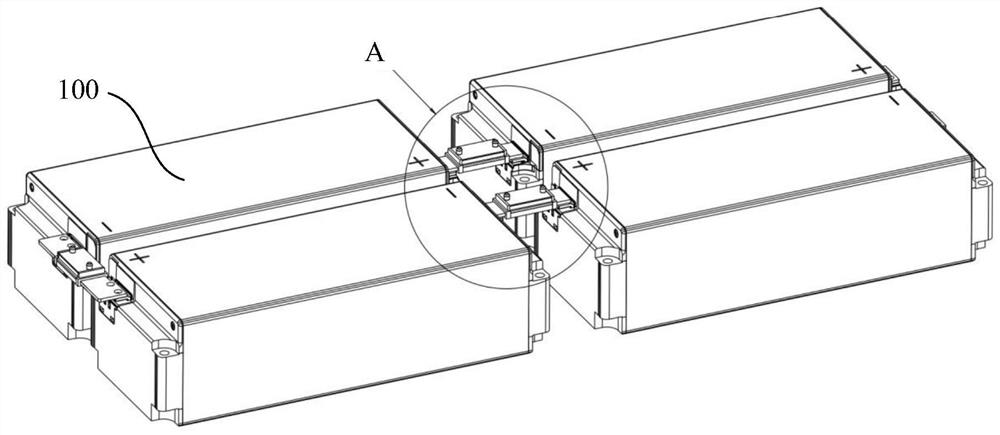

Battery thermal management device and power battery system for vehicle

A battery thermal management and battery system technology, applied in the field of battery thermal management devices, can solve the problems of low cooling efficiency, affecting system cycle life, low heating efficiency, etc., and achieve the goal of improving heat conduction efficiency, optimizing heat transfer path, and reducing device cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The implementation and use of the embodiments are discussed in detail below. It should be understood, however, that the specific embodiments discussed are merely illustrative of specific ways to make and use the invention, and do not limit the scope of the invention. In the description, the structural positions of various components, such as directions such as upper, lower, top, and bottom, are not absolute, but relative. These directional representations are appropriate when the various components are arranged as shown in the figures, but when the positions of the various components in the figures are changed, the directional representations also change accordingly.

[0034]In this document, terms such as "mounted", "connected", "connected" and "fixed" should be interpreted in a broad sense unless otherwise expressly specified and limited. For example, it can be a fixed connection, or a detachable connection, or integrated; it can be a mechanical connection, or it can...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap