Kitchen garbage pyrohydrolysis device and method

A kitchen waste and thermal hydrolysis technology, which is applied to chemical instruments and methods, transportation and packaging, and solid waste removal, can solve the problems of low steam recycling rate, high hidden dangers in production safety, and low waste disposal efficiency. Achieve the effects of improving production efficiency, facilitating automated production, and overcoming sequential batch production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0040] According to an embodiment of the present invention, the device further includes a balance tank, the balance tank includes two air inlets, the two air inlets are respectively opened to the feed balance section and the discharge balance section The balance tank is a steel pressure vessel, the balance tank is provided with a pressure relief port, and the pressure in the tank rises after being connected with the feed and discharge balance sections, and the pressure is released to normal through the pressure relief port before the next connection. pressure; preferably, the volume of the balance tank is 10 times or more the volume of the feed balance section.

[0041] According to an embodiment of the present invention, the feed balance section is connected to the feed port of the thermal hydrolysis tank through a first on-off valve; the feed balance section is connected to the thermal hydrolysis tank through a first stop valve connection, the first shut-off valve is configu...

Embodiment

[0088] The materials, reagents, etc. used in the following examples can be obtained from commercial sources unless otherwise specified.

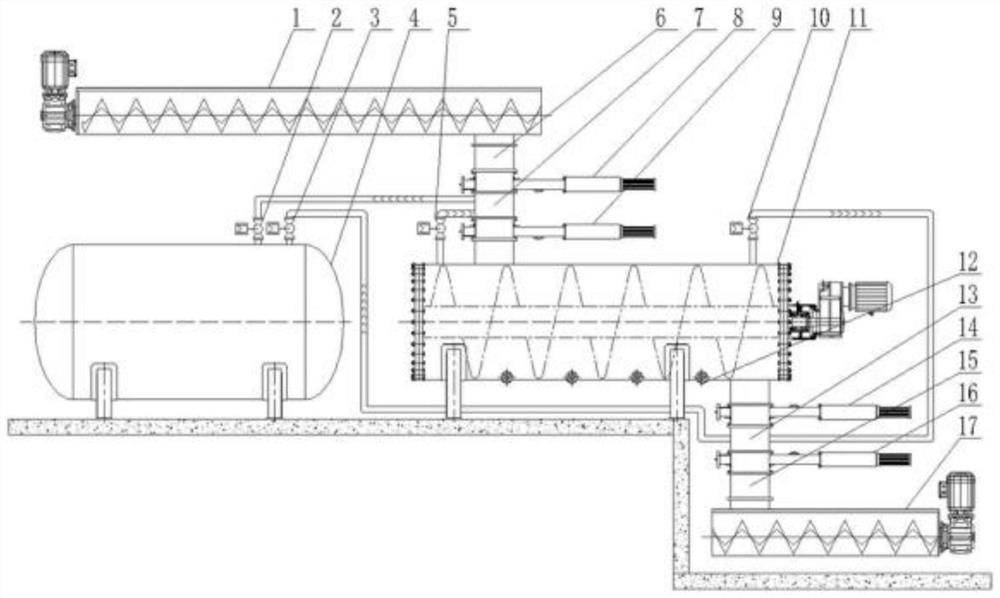

[0089] example figure 1 As shown, a kitchen waste continuous thermal hydrolysis device provided by the present invention includes a feed conveyor 1, a feed storage section 6, a feed balance section 7, a horizontal thermal hydrolysis tank 11, an outlet Material balance section 13, material discharge storage section 15, discharge conveyor 17 and balance tank 4.

[0090] A screw conveying device is provided inside the horizontal thermal hydrolysis tank 11 . The top of the horizontal thermal hydrolysis tank 11 is provided with a feed port and a communication port communicating with the feed storage section 6 and the feed balance section 7 . The bottom of the horizontal thermal hydrolysis tank 11 is provided with several discharge ports and steam inlets 12 . The conveying channel from the feed conveyor 1 to the feed port of the horizontal ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com