Transition box for battery processing and battery assembling equipment

A technology of battery assembly and transition box, which is applied in the direction of battery assembly, secondary battery manufacturing, sustainable manufacturing/processing, etc., and can solve the problem of inability to transition materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

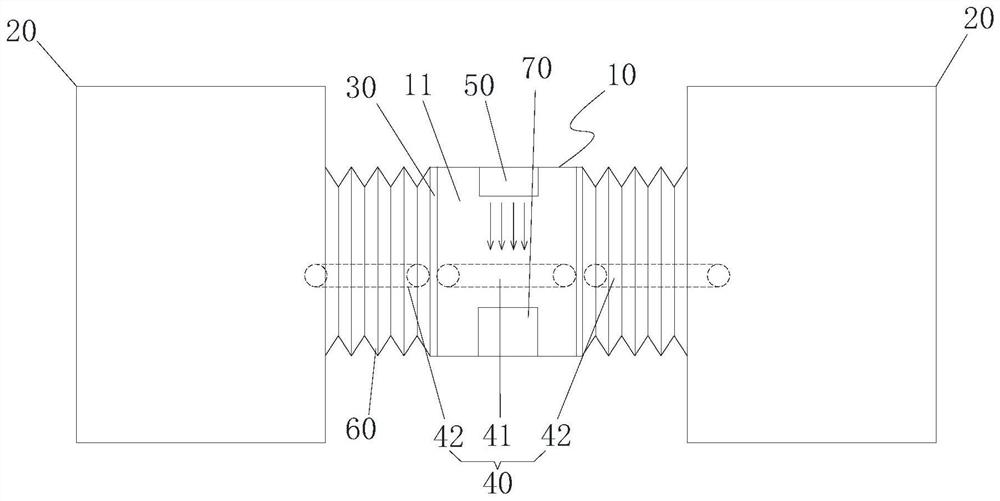

[0026] Such as figure 1 As shown, this embodiment discloses a transition box for battery processing, the transition box includes a housing 10, a box door 30, a conveying device 40 and a dust removal device 50, the housing 10 has a transition chamber 11 and a material port 12, the transition The cavity 11 is connected to the processing unit 20 through the material port 12; the box door 30 is arranged at the position of the material port, and the box door 30 is used to open or close the material port; the conveying device 40 is used to produce materials between the transition box and the processing unit 20 The dust removal device 50 is arranged in the transition chamber 11, and the dust removal device 50 is used to remove dust from the materials in the transition chamber 11. The transition box for battery processing of the present invention is provided with a transition cavity and a box door. When the box door 30 is opened, the transition cavity 11 communicates with the processi...

Embodiment 2

[0029] On the basis of Example 1, such as figure 1 As shown, the conveying device 40 includes an inner conveyor belt 41 and an outer conveyor belt 42. The inner conveyor belt 41 is arranged in the housing 10; the outer conveyor belt 42 is arranged outside the housing 10, and there is a gap between the inner conveyor belt 41 and the outer conveyor belt 42. When 30 was closed, the chamber door 30 was in the position gap. Wherein, the outer conveyor belt is used to transport materials to the inner conveyor belt, or, the materials transported by the inner conveyor belt can also be transported to the processing unit. There can be one or two outer conveyor belts. A gap is set between the outer conveyor belt and the inner conveyor belt, which can ensure that the box door will not interfere with the outer conveyor belt when it is closed, thereby realizing the sealing of the casing.

Embodiment 3

[0031] On the basis of Example 2, such as figure 1 As shown, the dust removal device 50 is arranged above the inner conveyor belt 41 , and an air cleaning device is arranged below the inner conveyor belt 41 . The dust removal device can blow out high-speed airflow downwards, and remove the dust on the material through the action of the high-speed airflow. By setting the dust removal device 50 above the inner conveyor belt and the air purification device 70 below, the air purification device can be connected with the dust removal device above. With the cooperation of the device, the blowing dust can be directly purified to achieve the dust removal effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com