Multifunctional self-propelled operation trolley for welding steel arch rib sections

A multi-functional, self-propelled technology, applied in the direction of traveling mechanism, load suspension components, lifting devices, etc., can solve the problems of large construction environment restrictions, low support construction efficiency, high operation risk, etc., to save temporary safety measures investment, structure Simple and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

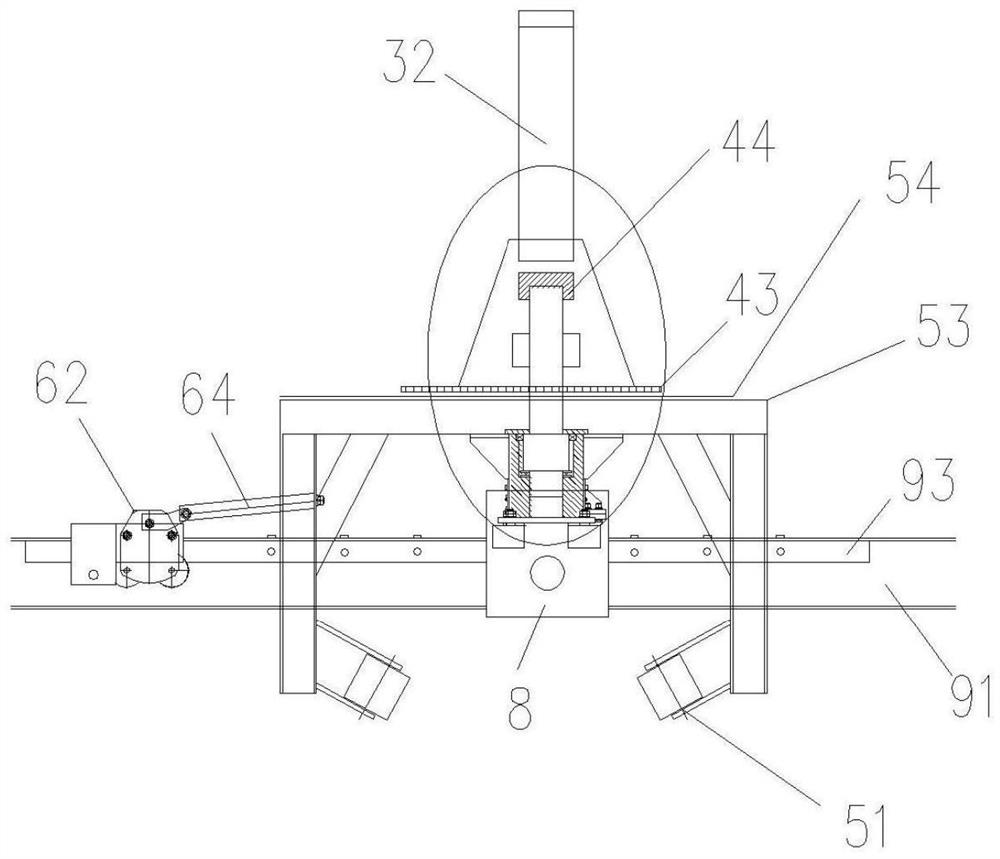

[0041] Referring to Figures 8 and 9, it also includes an anti-skid system 6, the anti-skid system 6 includes a latch 61, a base 62, a connecting rod 64 and a heel

[0043] Wherein, the rotating shaft 44 is connected to the inside of the bearing seat 47 through a thrust bearing 48, and the bottom of the rotating shaft 44

[0044] Wherein, the drive device 41 is connected to the support platform 54 of the balance frame 5 through bolts.

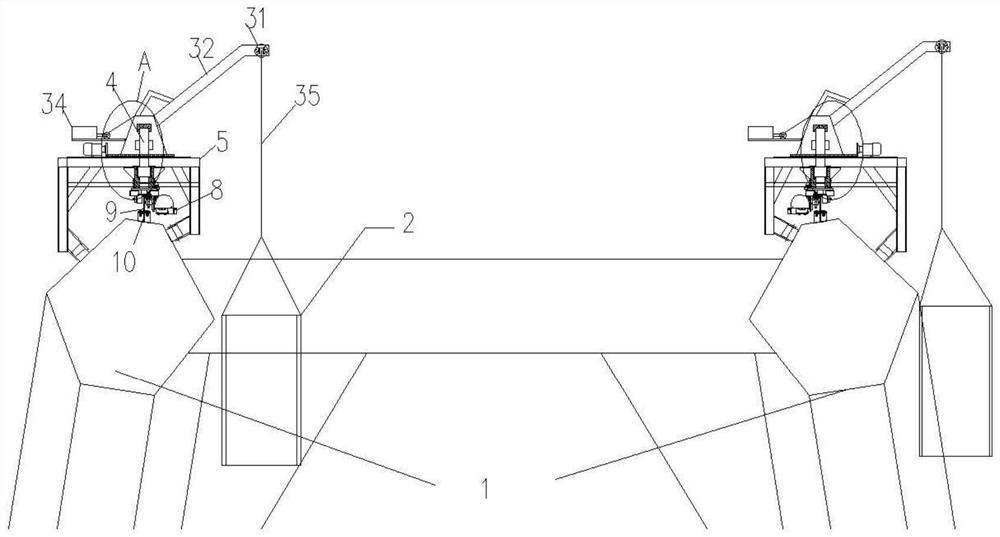

[0046] Wherein, the rail system 9 is connected with the steel arch rib 1 through the connecting seat 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com