Non-woven material capable of releasing negative ions and preparation method thereof

A technology of non-woven materials and negative ions, applied in the field of non-woven materials, can solve the problems of unstable combination, low content of adsorptive substances, poor adsorption and purification effect, etc., and achieve improved air purification effect, high production efficiency and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

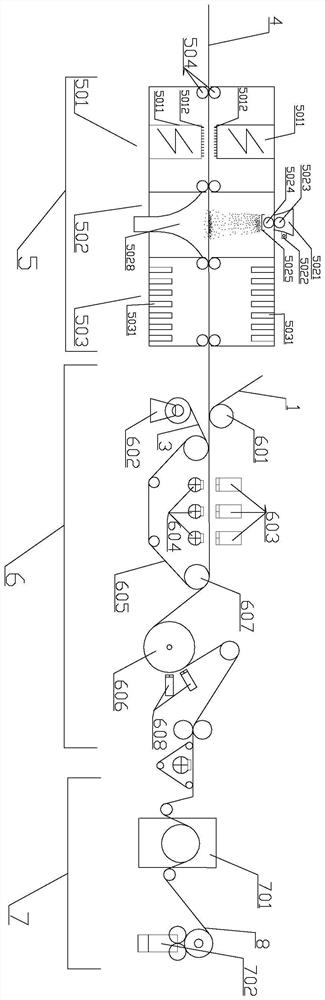

[0086] A preparation method of a non-woven material capable of releasing negative ions, comprising the following steps:

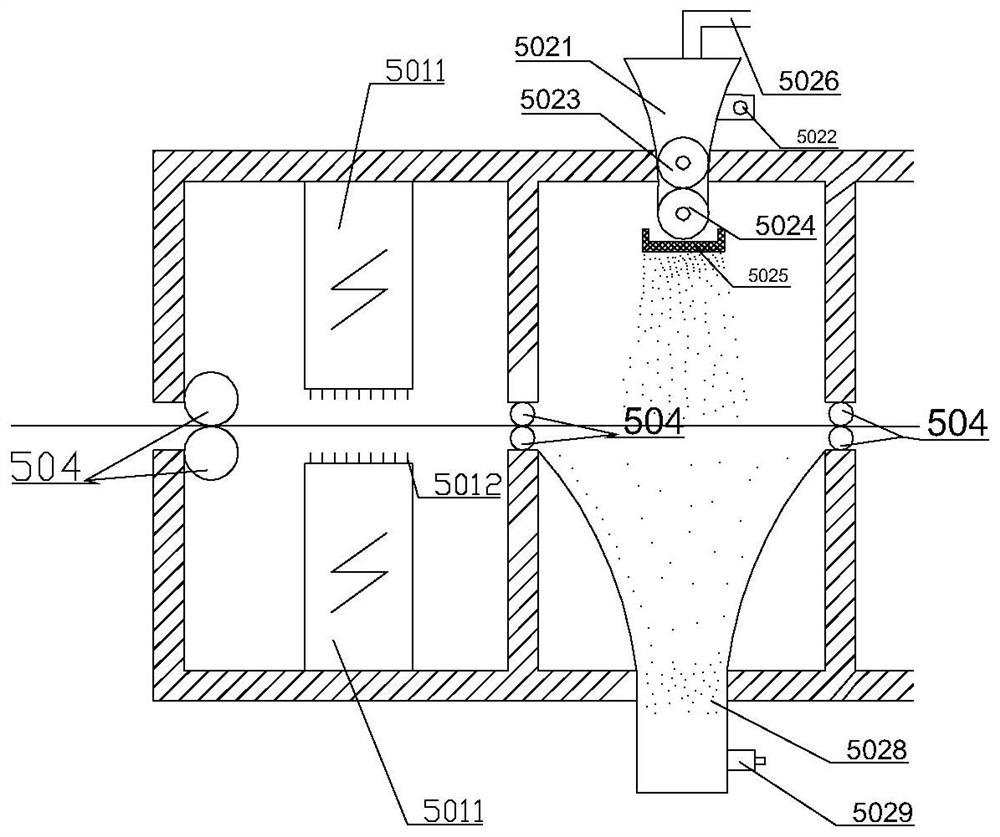

[0087] (1) Electret treatment (electret voltage 25-50kV, electret distance 4-8cm) is carried out on the low-melting fiber web (laid directly after spinning, without any rolling and reinforcement), and then pass through the powder The particle applying unit adsorbs the negative ion powder on the low-melting fiber web (the flow rate of the powder is 5-10g / s, and the temperature is 80-120°C) to obtain the low-melting fiber web adsorbed with the negative ion powder; continue to the low-melting fiber The net is rolled;

[0088] (2) performing far-infrared drying treatment at 150-170° C. on the low-melting fiber web adsorbed with negative ion powder particles, so that the low-melting point fibers are melted to fix the negative ion powder particles to make a second fiber layer;

[0089] (3) mixing superabsorbent fibers with antibacterial fibers, and making a firs...

Embodiment 1

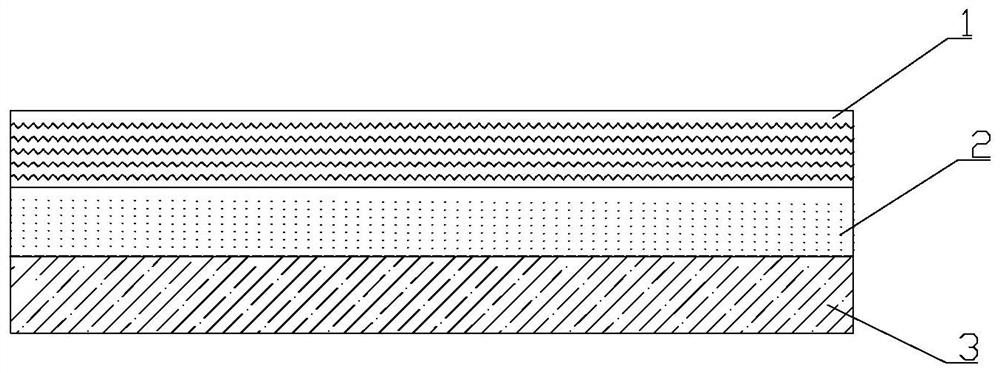

[0093] A non-woven material that can release negative ions, the mass per unit area is 60g / m 2 ,like figure 1 As shown, it includes a first fiber layer 1, a second fiber layer 2 and a third fiber layer 3 that are stacked and connected in sequence; the first fiber layer contains superabsorbent fibers and synthetic antibacterial fibers with a water absorption rate of 80 times; The second fiber layer includes low-melting fiber (polypropylene / polyester sheath-core bicomponent fiber filament, skin-core ratio is 30 / 70) and negative ion powder (800 mesh) attached to the low-melting fiber. ); the third fiber layer is a polypropylene spunbond hot-rolled non-woven fabric.

[0094] Wherein, the first fiber layer accounts for 10% of the total mass of the material; the superabsorbent fibers account for 10% of the mass of the first fiber layer; the second fiber layer accounts for 60% of the total mass of the material; the negative ion powder particles It accounts for 20% of the total mass ...

Embodiment 2

[0107] A non-woven material that can release negative ions, the mass per unit area is 120g / m 2 ,like figure 1 As shown, it includes a first fiber layer 1, a second fiber layer 2 and a third fiber layer 3 that are stacked and connected in sequence; the first fiber layer contains superabsorbent fibers and synthetic antibacterial fibers with a water absorption rate of 80 times; The second fiber layer includes low-melting fiber (polypropylene / polyester sheath-core bicomponent fiber filament, skin-core ratio is 50 / 50) and negative ion powder (1200 mesh) attached to the low-melting fiber. ); the third fiber layer is a polypropylene spunbond hot-rolled non-woven fabric.

[0108] Wherein, the first fiber layer accounts for 30% of the total mass of the material; the superabsorbent fibers account for 35% of the mass of the first fiber layer; the second fiber layer accounts for 50% of the total mass of the material; the negative ion powder particles It accounts for 15% of the total mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com