Semiconductor device

A semiconductor and conductive type technology, applied in semiconductor devices, transistors, electric solid devices, etc., can solve the problems of increased recovery current and reduced damage tolerance of diodes, and achieve the effect of improving damage tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

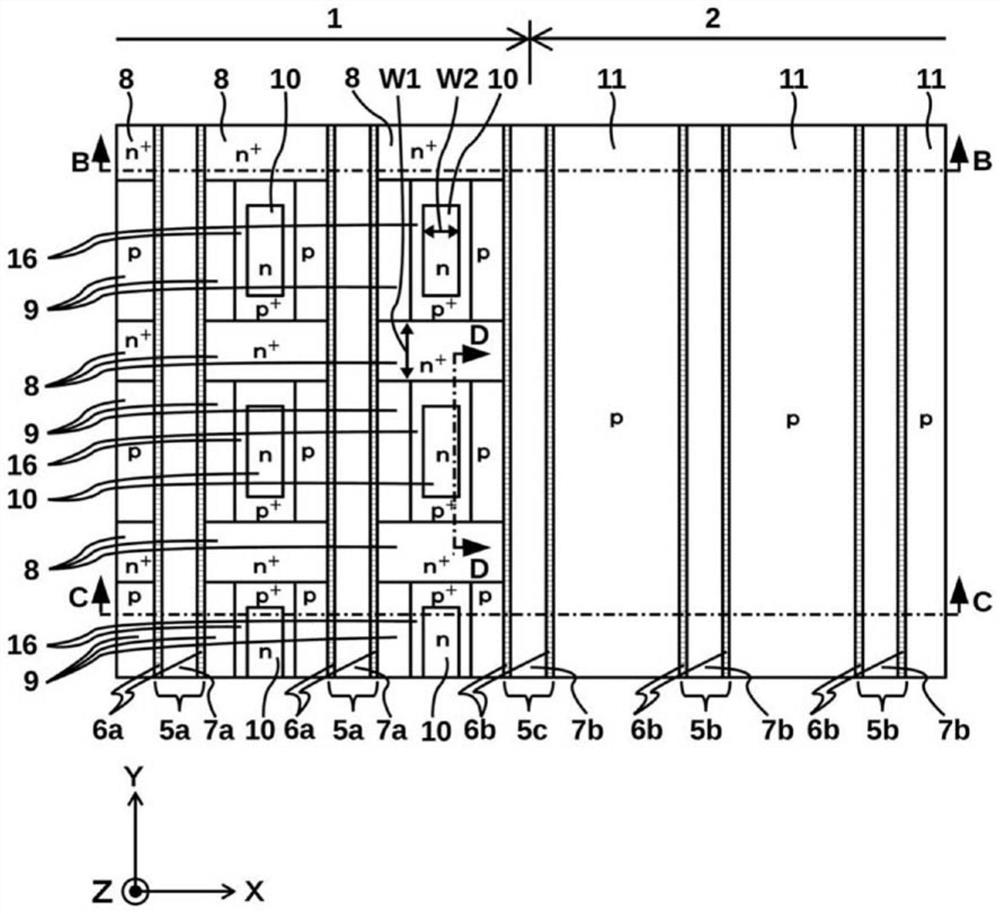

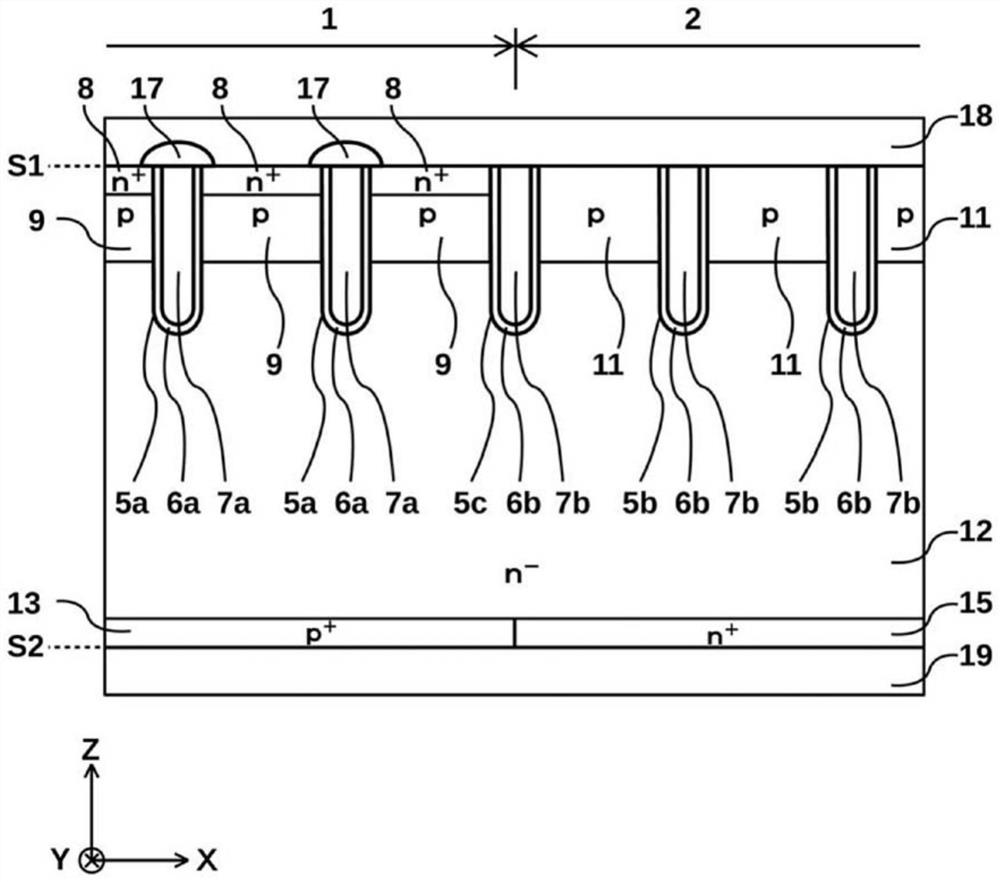

[0082] The semiconductor device according to Embodiment 1 suppresses the flow of holes h from the IGBT region 1 to the diode region 2 . Such as Figure 11 As shown, when the diode operates, holes h are injected from the p-type base layer 9 and the base contact layer 16 into the drift layer 12 of the diode region 2 . On the other hand, holes h are not injected from the n-type counter-doped layer 10 into the drift layer 12 of the diode region 2 . Therefore, by providing the anti-doped layer 10, compared with the case where the anti-doped layer 10 is not provided, the injection of holes h from the IGBT region 1 to the diode region 2 during diode operation can be suppressed. .

[0083] Therefore, by selectively providing the counter-doped layer 10 on the surface layer of the base layer 9 , the recovery current can be suppressed and the breakdown resistance at the time of the recovery operation can be improved. In addition, the concentration of the acceptor impurity in the surfa...

Embodiment approach 2

[0088] use Figure 13 and Figure 14 The structure of the semiconductor device according to Embodiment 2 will be described. Figure 13 and Figure 14 It is a plan view showing the semiconductor device according to the second embodiment. Figure 14 will be Figure 13 The enlarged view of part E described is a plan view showing the structure of the first principal surface side of the semiconductor substrate. exist Figure 14 In , the description of electrodes and the like provided on the upper side of the first main surface of the semiconductor substrate is omitted. exist Figure 13 and Figure 14 For convenience of description, XYZ orthogonal coordinate axes indicating directions are also shown in FIG. In addition, in Embodiment 2, the same constituent elements as those described in Embodiment 1 are assigned the same reference numerals and their descriptions are omitted.

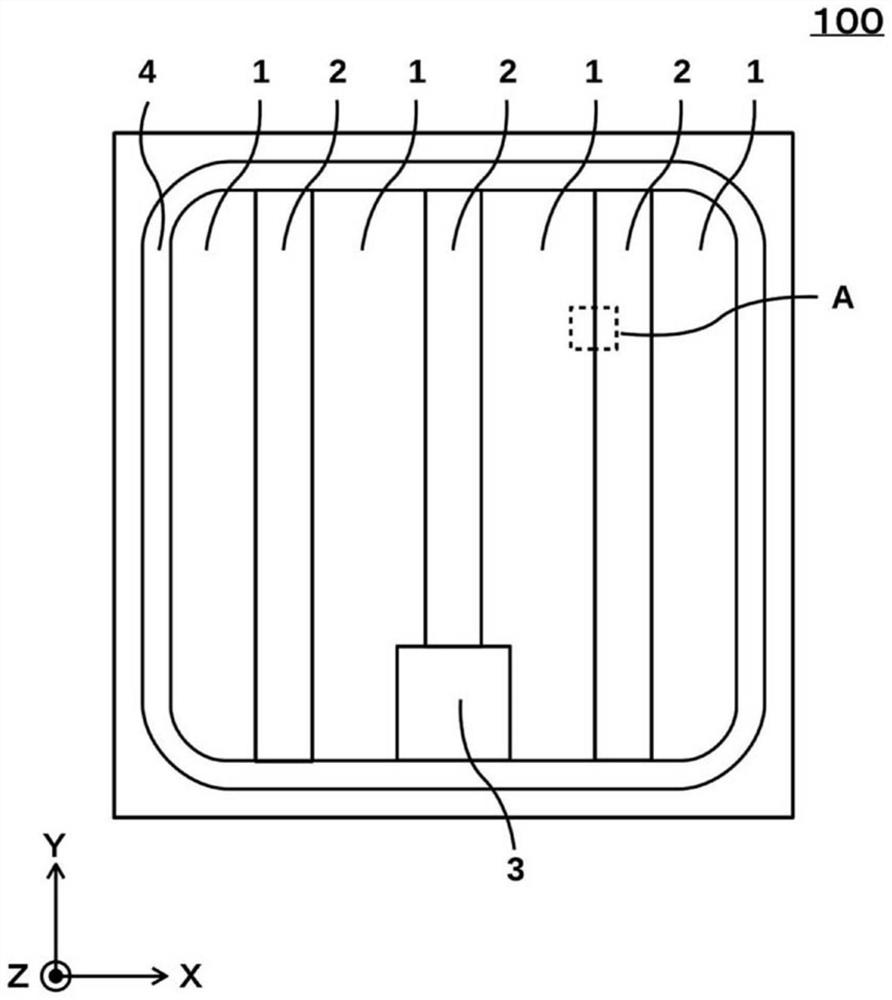

[0089] Such as Figure 13 As shown, in the semiconductor device 200 according to Embodiment 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com