A method for preparing graphene network toughened zrc-sic ultra-high temperature ceramic material

A technology of ultra-high temperature ceramics and graphene, which is applied in the field of preparation of ceramic materials, can solve the problems of ZrC-SiC poor damage tolerance and achieve the effect of improving the damage tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

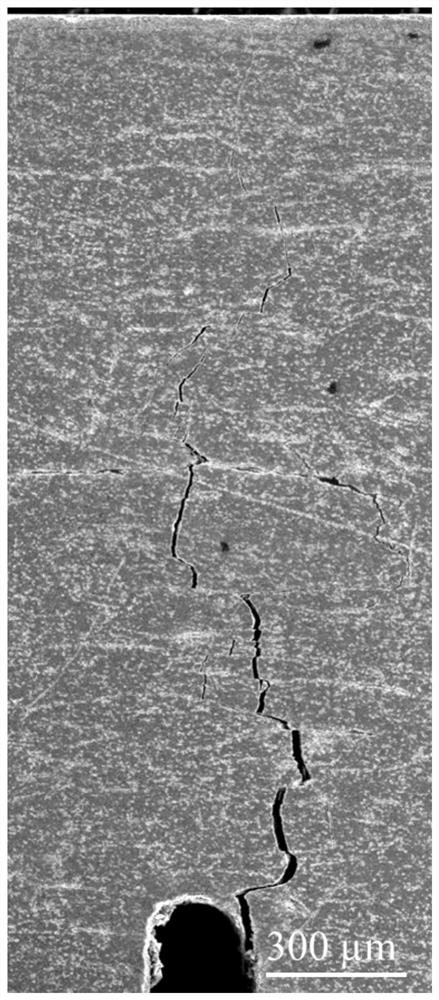

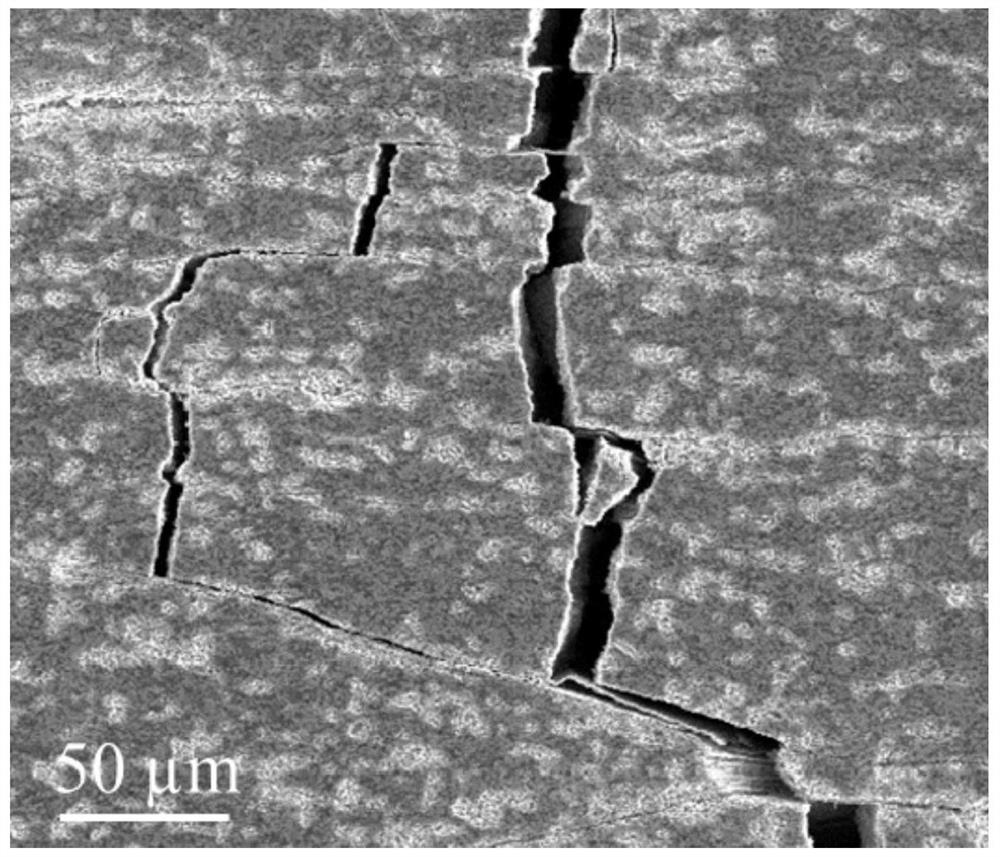

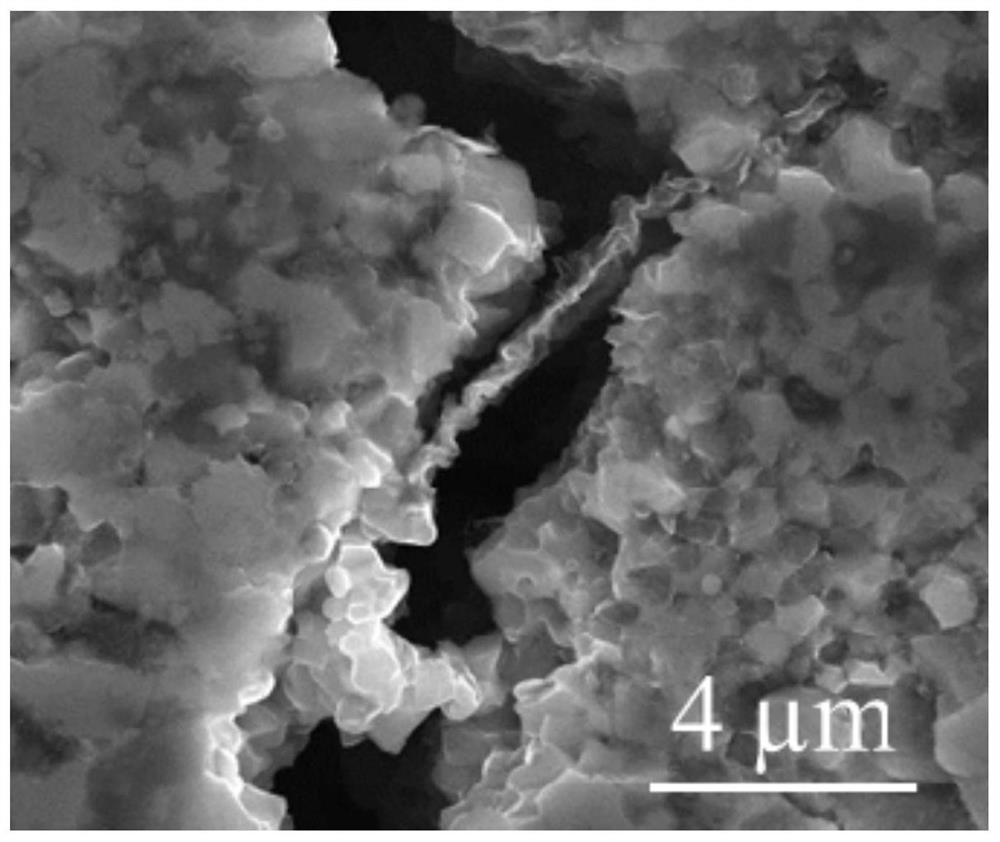

Image

Examples

specific Embodiment approach 1

[0023] Embodiment 1: In this embodiment, a method for preparing a graphene network toughened ZrC-SiC ultra-high temperature ceramic material is carried out according to the following steps:

[0024] 1. Add graphene oxide powder into deionized water, stir thoroughly for 20-30 minutes, and ultrasonically for 10-15 minutes to obtain graphene oxide aqueous solution;

[0025] 2. Add polyvinyl alcohol to the graphene oxide aqueous solution obtained in step 1, and stir continuously for 20 to 30 minutes to obtain a graphene oxide dispersion;

[0026] 3. Put the graphene oxide dispersion obtained in step 2 into a directional freezer, pre-freeze for 6-10 hours at a temperature of -20 to -10°C, and then vacuum freeze-dry to obtain a PVA-modified graphene network ;

[0027] 4. Thermally reduce the PVA-modified graphene network obtained in step 3 at a temperature of 70-100°C for 5-10 hours, then put it into a vacuum impregnation device, impregnate the ceramic slurry, and then vacuum-dry t...

specific Embodiment approach 2

[0029] Embodiment 2: This embodiment is different from Embodiment 1 in that: in Step 1, the graphene oxide has 3-5 layers. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in step 1, the ultrasonic power is 100W, and the frequency is 180KHz. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com