Explosion-proof shell, manufacturing method thereof and battery with explosion-proof shell

A technology of explosion-proof casing and manufacturing method, which is applied to large-sized batteries/battery packs, small-sized batteries/battery packs, battery pack components, etc., and can solve the problem of uneconomical and reliable manufacturing methods for engraving and insufficient deformation Space explosion-proof pressure relief, explosion-proof structure takes up a lot of space, etc., to achieve the effect of facilitating automated production, ensuring effective space, and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

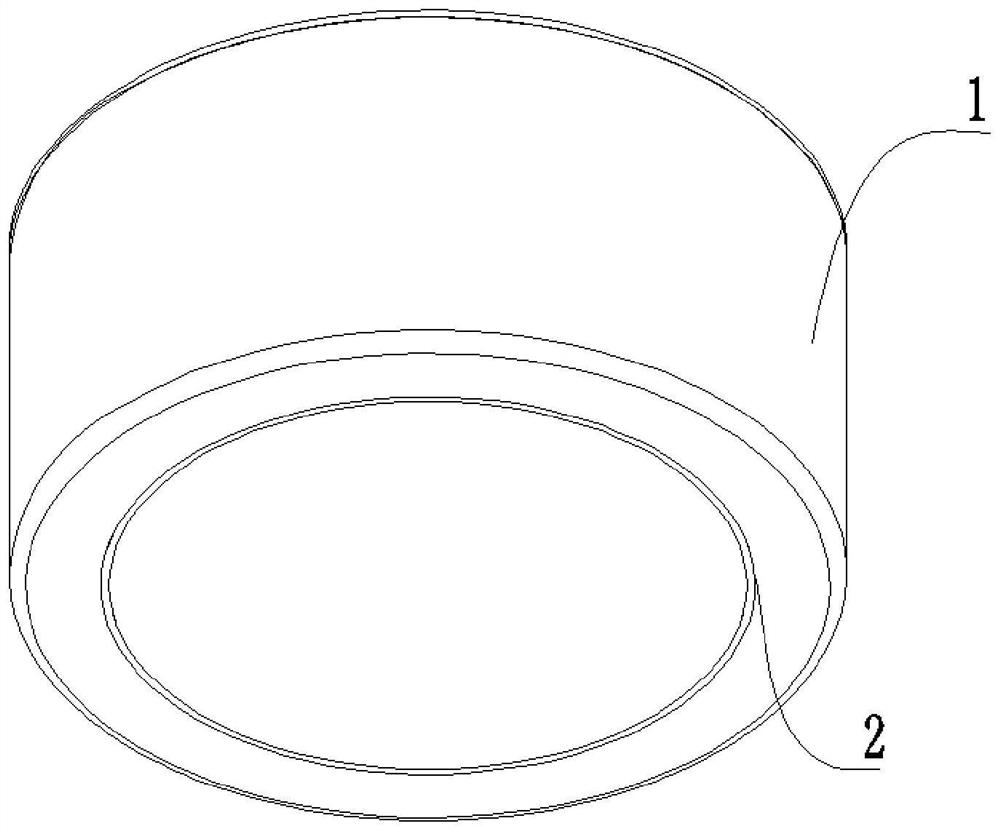

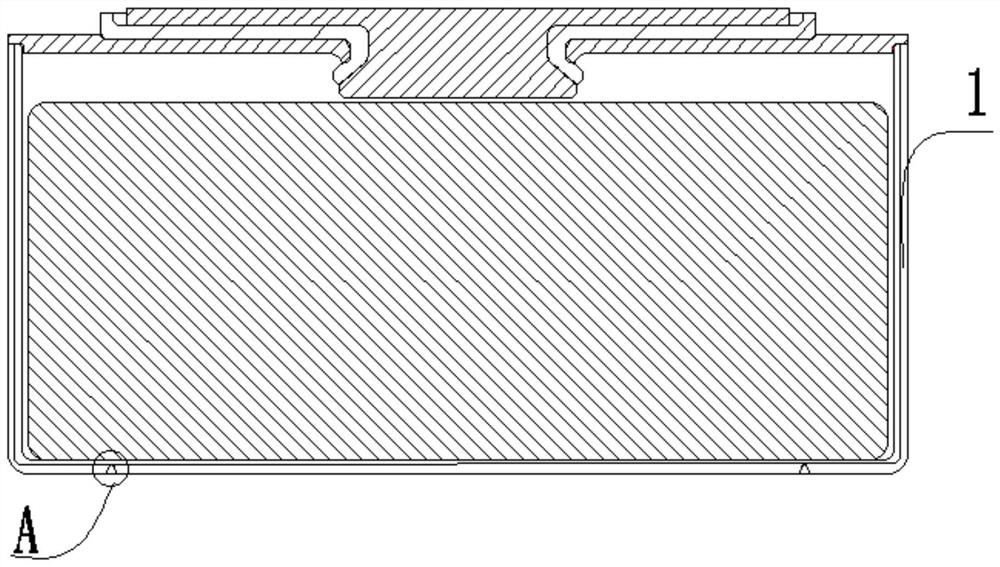

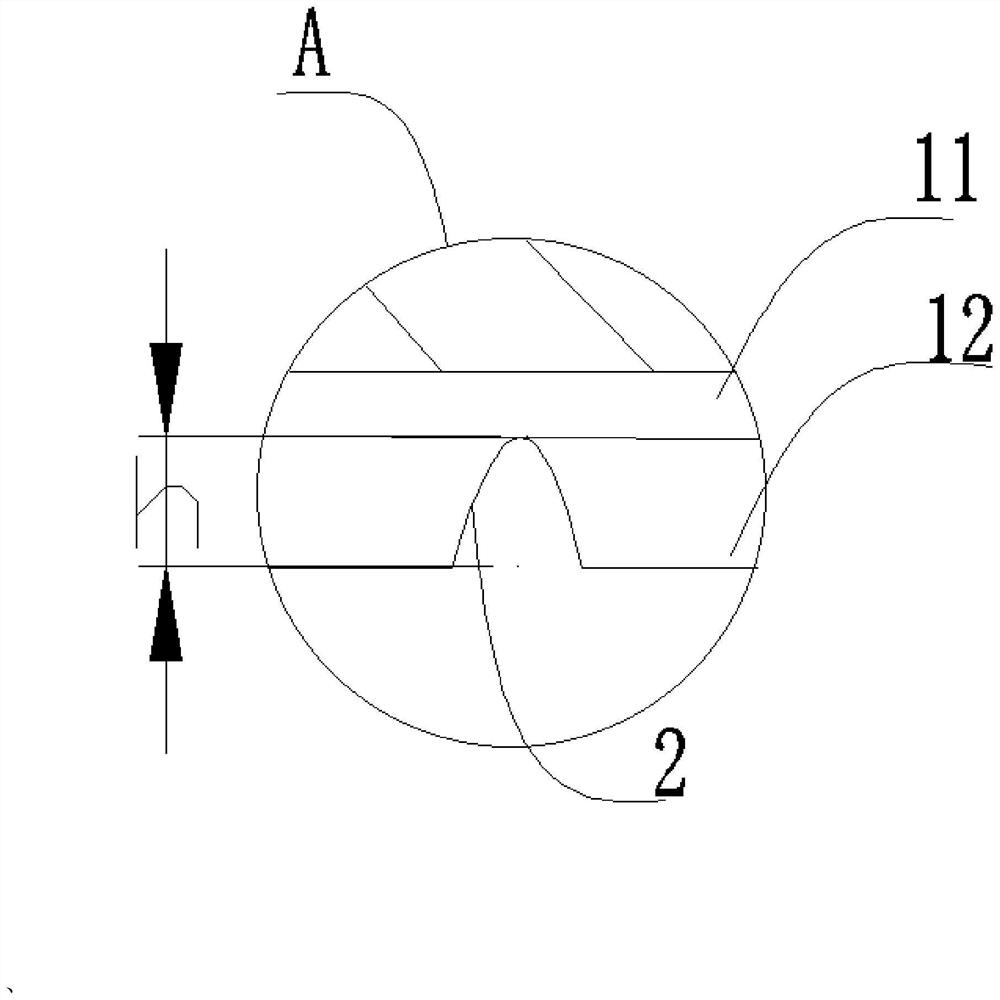

[0041] Such as Figure 1-3 As shown, it is Embodiment 1 of the present invention, an explosion-proof enclosure, comprising: a housing body 1, the housing body 1 is a double-layer composite structure, the double-layer composite structure includes an inner layer 11 and an outer layer 12, and the inner layer 11 and the outer layer The layers 12 are tightly pressed together; the outer layer 12 on one side of the shell body 1 is provided with an explosion-proof groove 2, which extends along the circumferential direction of the shell body 1, and the explosion-proof groove 2 is ring-shaped, and the depth h of the explosion-proof groove 2 is equal to that of the outer layer 12 thickness, the bottom of the explosion-proof groove 2 is provided with an opening, and the surface part of the inner layer 11 is exposed to the opening; the normal working pressure in the housing body 1 is set as pressure P, if the pressure in the housing body 1 is greater than the pressure P, The inner layer 11...

Embodiment 2

[0052] Such as Figure 4-6 As shown, it is the second embodiment of the present invention. The difference from the first embodiment is that the outer layer 12 on one side of the shell body 1 is also provided with a first weakened portion 3 and a second weakened portion 4. The first weakened portion The part 3 and the second weakened part 4 both extend along the circumferential direction of the shell body 1, the first weakened part 3 and the second weakened part 4 are both ring-shaped, and the first weakened part 3 surrounds the second weakened part 4; the explosion-proof groove 2 is arranged on the second Between the first weakened portion 3 and the second weakened portion 4 . The explosion-proof groove 2 is directly exposed, and is easily damaged and deformed by collision, extrusion, etc. during production, transportation and use. By hiding the explosion-proof groove 2 between the first weakened part 3 and the second weakened part 4, it can avoid damage caused by collision o...

Embodiment 2

[0055] The manufacturing method of making embodiment two explosion-proof casing comprises the following steps:

[0056] S1: Select the preliminarily formed shell body 1, which is a double-layer composite structure, which includes an inner layer 11 and an outer layer 12, and the inner layer 11 and the outer layer 12 are tightly pressed together.

[0057] S2: The first weakened part 3 and the second weakened part 4 are formed by thinning the outer layer 12 on one side of the shell body 1, and both the first weakened part 3 and the second weakened part 4 extend along the circumferential direction of the shell body 1, Both the first weakened part 3 and the second weakened part 4 are annular, the first weakened part 3 surrounds the second weakened part 4, and an explosion-proof groove 2 is opened between the first weakened part 3 and the second weakened part 4, and the explosion-proof groove 2 It is annular, and the depth h of the explosion-proof groove 2 is equal to the thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com