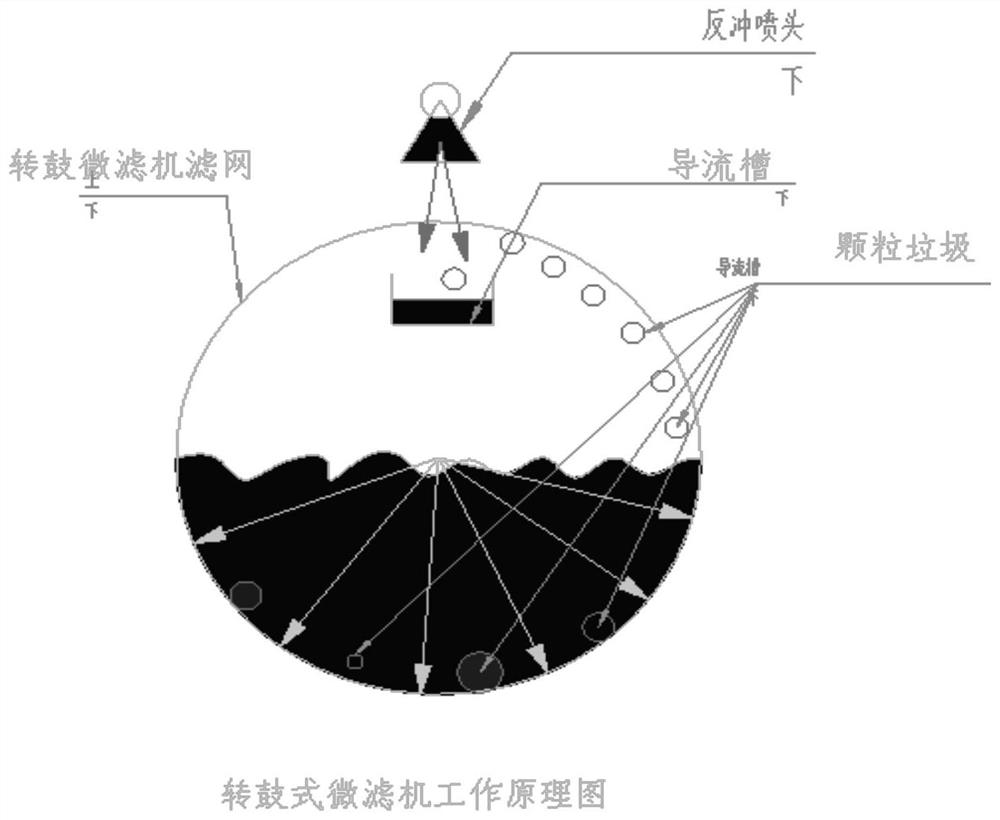

Vertical flow type micro-filter and working method thereof

A microfiltration machine, vertical flow technology, applied in the direction of separation methods, chemical instruments and methods, fixed filter element filters, etc., can solve the problems of small filtration particle size range and low filtration efficiency, and achieve good sewage discharge effect and reduce The probability of network blocking and better filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

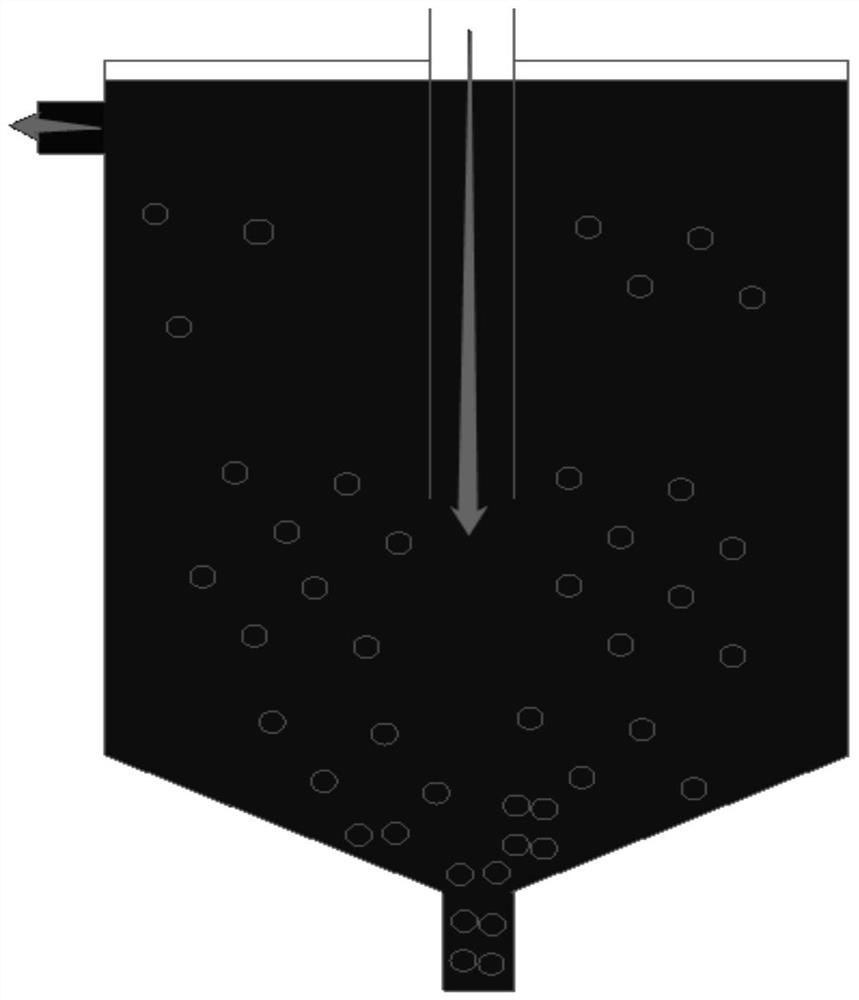

[0030] Embodiment 1: The present invention proposes a vertical flow microfiltration machine, comprising a microfiltration body 1, the lower part of the microfiltration body 1 is provided with a vertical flow separation chamber 5, and the lower part of the microfiltration body 1 is arranged below the vertical flow separation chamber 5. There is a sewage outlet 10, and the sewage outlet 10 is connected to a sewage pipe 6. The microfiltration body 1 is provided with a brush reciprocating mechanism 7 above the vertical flow separation bin 5, and the microfiltration body 1 is located above the brush reciprocating mechanism 7. There is a filter screen 8, a water outlet pipe 2 is arranged on the upper side of the microfiltration body 1, a water level sensor 3 and a sewage level sensor 3 distributed up and down are arranged on the upper side of the microfiltration body 1, and the lower side of the microfiltration body 1 is provided. A water inlet pipe 9 is provided at a position close ...

Embodiment 2

[0037] Embodiment 2: The present invention also proposes a working method of a vertical flow microfiltration machine, comprising the following steps:

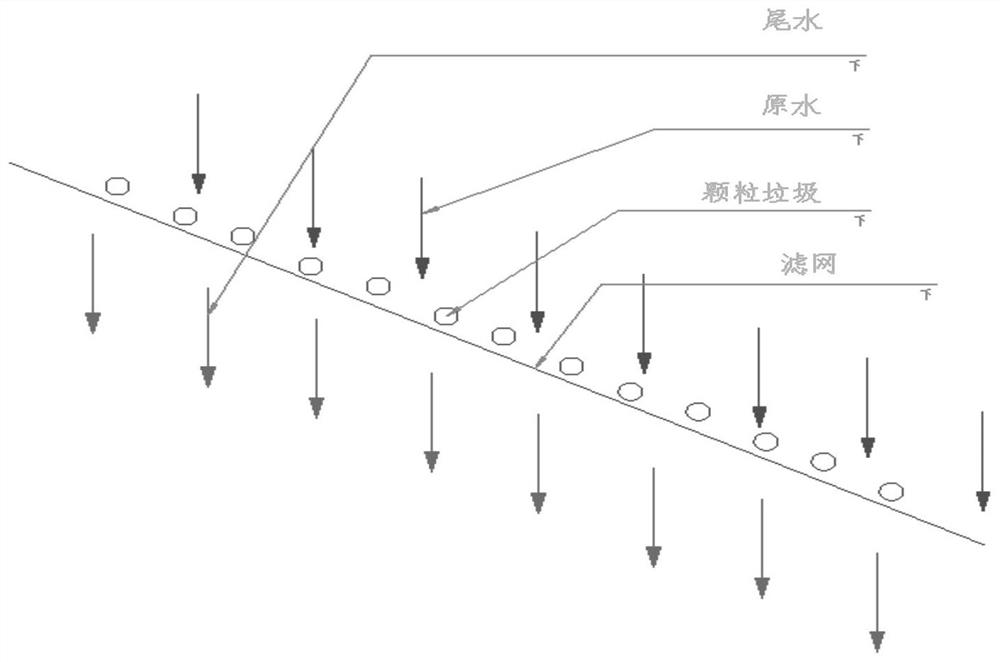

[0038] The positive flushing step specifically includes: the sewage enters the vertical flow separation bin 5 through the water inlet pipe 9, and then flows out through the water outlet pipe 2, the large specific gravity particles in the sewage settle and collect in the sewage outlet 10, and the small specific gravity garbage in the sewage will be filtered by the filter 8. Block it until the vertical flow separation bin 5 has too much garbage and affects the water level, and transfers to the backwashing step;

[0039] The backwashing step specifically includes: the sewage valve 11 is opened, the water inlet pipe 9 is closed at the same time, the direction of the water flow through the filter screen 8 is reversed, and the large and small particles of garbage are discharged from the microfiltration body 1 through the sewage pipe 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com