Ru-based catalyst for hydrogen production through ammonia decomposition and preparation method of Ru-based catalyst

A catalyst and ammonia decomposition technology, applied in the field of hydrogen production by ammonia decomposition, can solve the problems of low low temperature catalytic activity, etc., and achieve the effects of increasing specific surface area, improving treatment efficiency, and enhancing interaction

Active Publication Date: 2022-06-03

FUZHOU UNIV

View PDF12 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

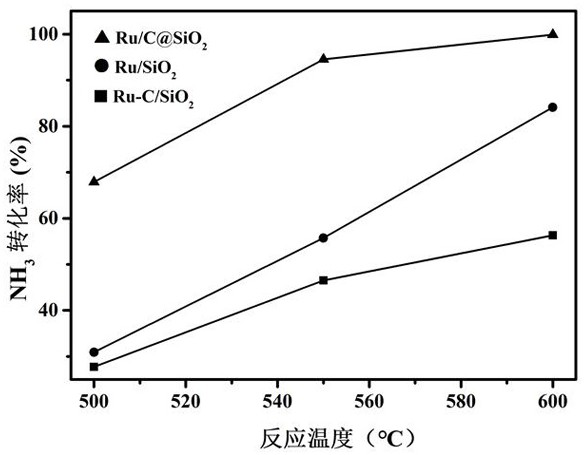

[0007] Therefore, the technical problem to be solved by the present invention is to overcome the low-temperature catalytic activity of the ammonia decomposition catalyst in the prior art, and provide a low-temperature catalytic activity high and ammonia decomposition effect Good ammonia decomposition catalyst with high ammonia treatment efficiency and high stability, preparation method and application thereof

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

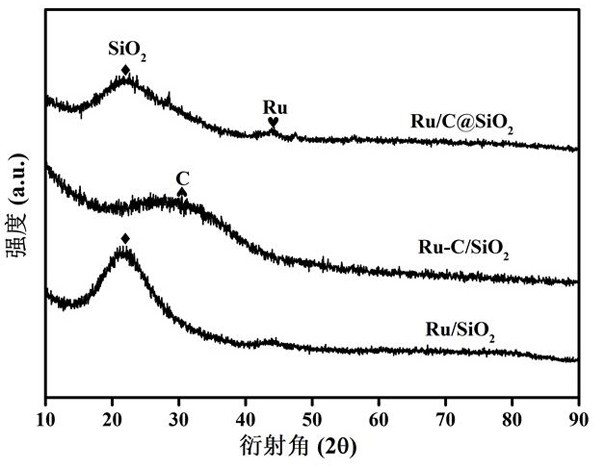

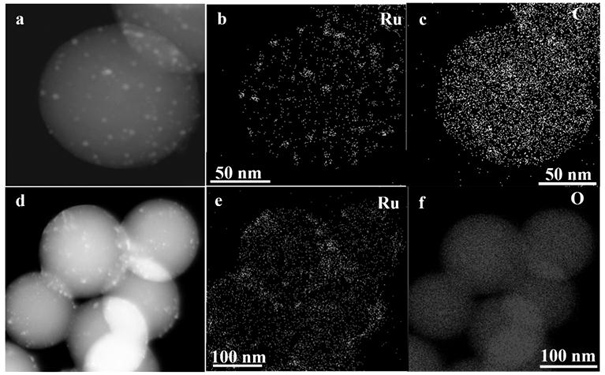

Login to View More Abstract

The invention relates to a Ru-based catalyst for hydrogen production through ammonia decomposition and a preparation method of the Ru-based catalyst. The catalyst comprises an active component and a carrier, the active component is active metal ruthenium, and the carrier is carbon layer coated silicon dioxide; according to the catalyst, carbon layer modified SiO2 is introduced to serve as a carrier of the ammonia decomposition catalyst, the surface alkalinity of the prepared catalyst is high, and meanwhile strong interaction is formed between the carrier and active metal; according to the present invention, with the catalyst, the electron transfer between the carrier and the active metal can be easily enhanced, the interaction between the active component and the decomposition product NH2, N or H of NH3 can be weakened, the electron transfer between the active component and the carrier and the desorption of the products N2 and H2 can be promoted, the low temperature activity of the catalyst can be improved, and the ammonia decomposition efficiency can be improved.

Description

technical field [0001] The invention belongs to the technical field of hydrogen production by ammonia decomposition, and in particular relates to a catalyst for hydrogen production by ammonia decomposition and a preparation method thereof. Background technique [0002] Hydrogen (H 2 ) is an ideal energy carrier and clean energy provider. Under the dual-carbon goal, hydrogen energy is regarded as one of the best solutions to solve energy and environmental problems. However, the existing relatively mature high-pressure hydrogen storage technology restricts the wide application of hydrogen energy due to the high cost of storage and transportation; therefore, various in-situ hydrogen production technologies emerge as the times require. [0003] Ammonia has a high hydrogen content (17.6 wt%), and can be liquefied at room temperature and 8 atm, and my country's ammonia industry chain is very mature; ammonia is decomposed to produce hydrogen (2NH). 3 → 3H 2 + N 2 ) The reacti...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J23/46B01J27/24B01J37/10B01J37/08C01B3/04

CPCB01J23/462B01J27/24B01J37/10B01J37/08C01B3/047Y02E60/50Y02E60/36

Inventor 罗宇欧阳东陈崇启江莉龙林立

Owner FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com