Ultra-thin special water-based ink for gravure printing and preparation method thereof

A technology of gravure printing and water-based ink, applied in the field of ink, can solve the problems of viscosity drop, short shelf life of water-based ink, poor anti-curl effect, etc., achieve better effect and ensure connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

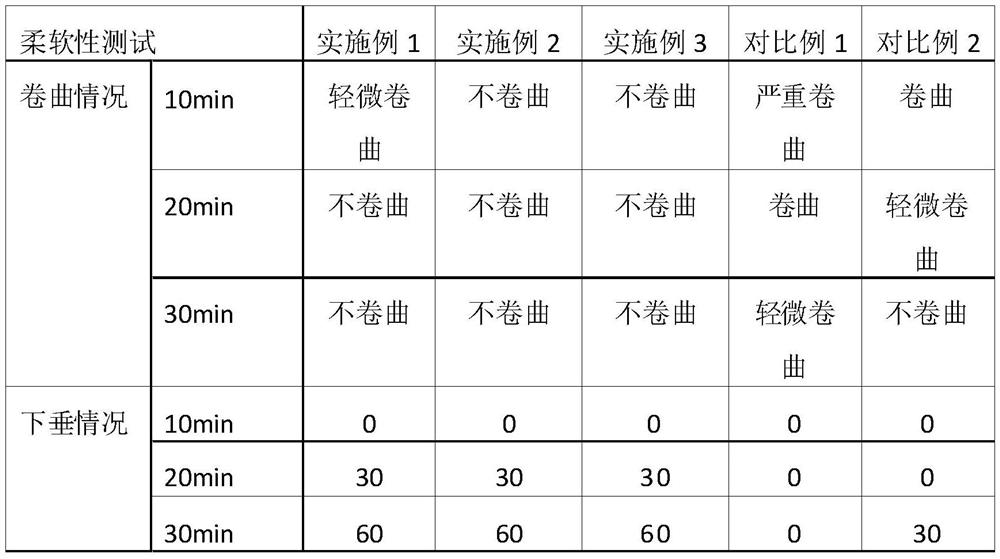

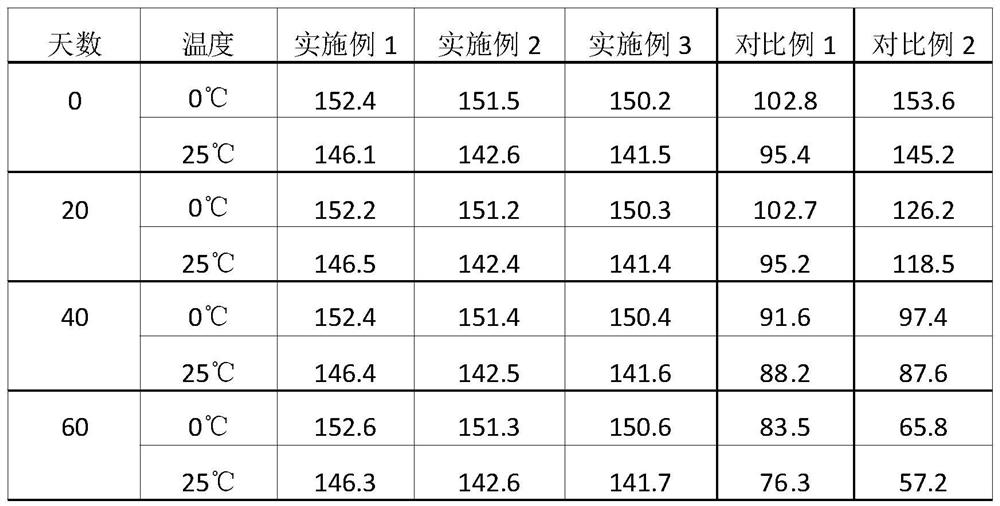

Examples

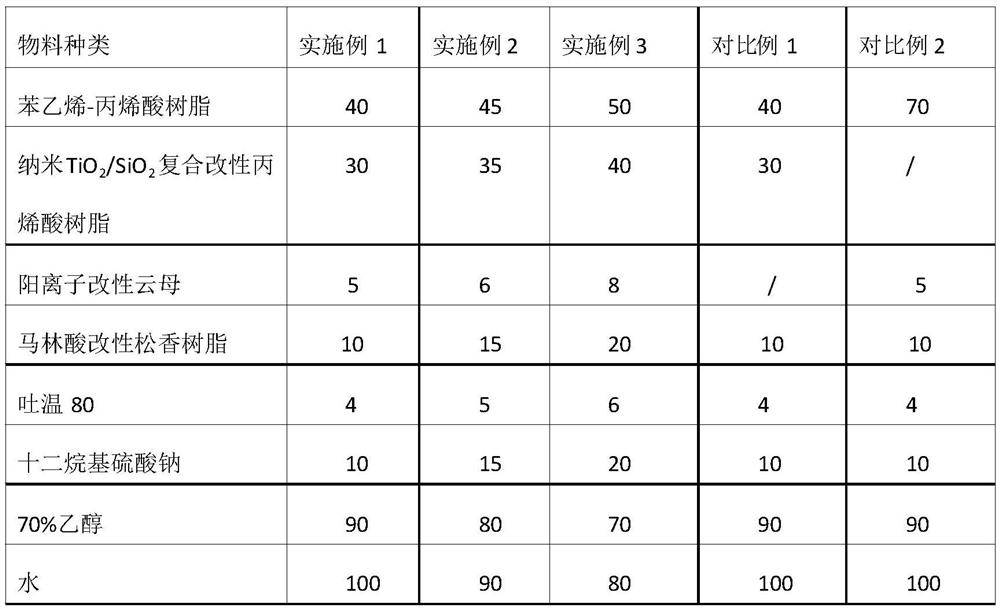

Embodiment 1

[0025] The specific raw materials are weighed according to Table 1, and the preparation steps are as follows:

[0026] (1) Mix half the amount of water and ethanol with styrene-acrylic resin and nano-TiO 2 / SiO 2 Compound modified acrylic resin and maleic acid modified rosin resin, and stirred at 60°C for 40min at 800r / min to obtain mixture A;

[0027] (2) mixing the cationic modified mica, Tween 80, sodium lauryl sulfate and the remaining formula amounts of water and ethanol, and stirring at 65° C. at 400 r / min for 15 min to obtain mixture B;

[0028] (3) Add mixture B to mixture A, and stir at 1100 r / min at 45°C for 1.5 h to obtain mixture C;

[0029] (4) Use a sander to grind the mixture C at 1200 r / min for 40 minutes, that is, it is obtained.

Embodiment 2

[0031] (1) Mix half the amount of water and ethanol with styrene-acrylic resin and nano-TiO 2 / SiO 2 Compound modified acrylic resin and maleic acid modified rosin resin, stirred at 70°C for 30min at 1000r / min to obtain mixture A;

[0032] (2) mixing the cationic modified mica, Tween 80, sodium lauryl sulfate and the remaining formula amounts of water and ethanol, and stirring at 75° C. at 600 r / min for 10 min to obtain mixture B;

[0033] (3) Add mixture B to mixture A, and stir at 1200 r / min at 55°C for 1 h to obtain mixture C;

[0034] (4) Use a sander to grind the mixture C at 300 r / min for 30 minutes, and then obtain.

Embodiment 3

[0036] (1) Mix half the amount of water and ethanol with styrene-acrylic resin and nano-TiO 2 / SiO 2 Compound modified acrylic resin and maleic acid modified rosin resin, stirred at 70°C for 40min at 1000r / min to obtain mixture A;

[0037] (2) mixing the cationic modified mica, Tween 80, sodium lauryl sulfate and the remaining formula amounts of water and ethanol, and stirring at 600r / min for 15min at 75°C to obtain mixture B;

[0038] (3) Add mixture B to mixture A, and stir at 1200 r / min at 55°C for 1.5 h to obtain mixture C;

[0039] (4) Use a sander to grind the mixture C at 1300r / min for 40min, that is, it is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com