PEDOT: PSS/EG/LiTFSI conductive ink, super-flexible electrode and electrophysiological signal monitoring method

A conductive ink, ultra-flexible technology, applied in diagnostic recording/measurement, ink, medical science, etc., can solve the problems of low conductivity and stretchability, achieve improved conductivity and stretchability, and good printing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

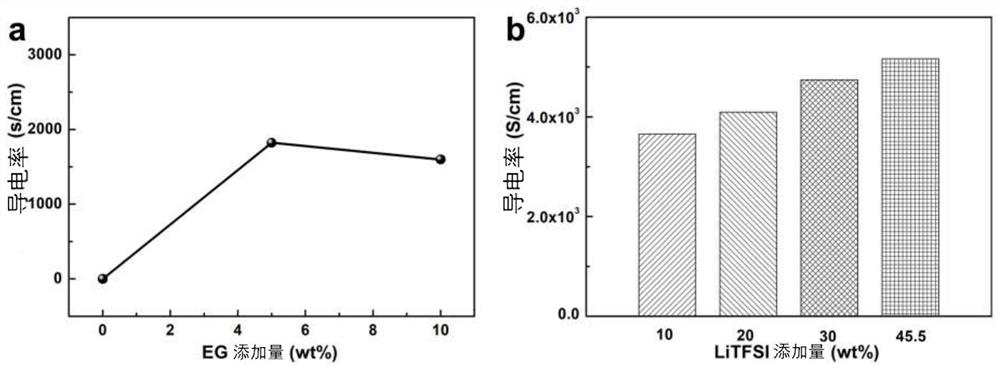

[0069] The present embodiment provides a method for modifying PEDOT:PSS with ethylene glycol and lithium bistrifluoromethanesulfonimide to obtain a PEDOT:PSS / EG / LiTFSI solution, which comprises the following steps:

[0070] 1) Prepare PEDOT:PSS / 5wt%EG / 10wt%LiTFSI solution

[0071] On the basis of the PEDOT:PSS / 5wt%EG solution prepared in Comparative Example 1, LiTFSI was added to make it account for 10wt% of the solid content of PEDOT:PSS, and the stirring was carried out. The stirring speed was 900r / min, and the stirring time was 15min. The PEDOT:PSS / 5wt%EG / 10wt%LiTFSI solution can be obtained.

[0072] 2) Viscosity test

[0073] The viscosity of the PEDOT:PSS / 5wt%EG / 10wt%LiTFSI solution was tested with a digital viscometer, and the viscosity was 23.8cP.

[0074] 3) Surface tension test

[0075] The surface tension of the PEDOT:PSS / 5wt%EG / 10wt%LiTFSI solution was tested with a surface tensiometer, and the surface tension was 36.7 mN / m.

[0076] 4) Preparation of flexible ...

Embodiment 2

[0082] The present embodiment provides a method for modifying PEDOT:PSS with ethylene glycol and lithium bistrifluoromethanesulfonimide to obtain a PEDOT:PSS / EG / LiTFSI solution, which comprises the following steps:

[0083] 1) Preparation of PEDOT:PSS / 5wt%EG / 20wt%LiTFSI solution

[0084] The addition amount of LiTFSI was changed to account for 20wt% of the total system, and other steps were the same as in Comparative Example 1.

[0085] 2) Viscosity test

[0086] The viscosity of the PEDOT:PSS / 5wt%EG / 20wt%LiTFSI solution was tested with a digital viscometer, and the viscosity was 20.2cP.

[0087] 3) Surface tension test

[0088] The surface tension of the PEDOT:PSS / 5wt%EG / 20wt%LiTFSI solution was tested with a surface tensiometer, and the surface tension was 35.5 mN / m.

[0089] 4) Preparation of flexible self-supporting PEDOT:PSS / 5wt%EG / 20wt%LiTFSI films

[0090] The preparation process is the same as in Example 1.

[0091] 5) Conductivity test

[0092] The conductivity ...

Embodiment 3

[0094] The present embodiment provides a method for modifying PEDOT:PSS with ethylene glycol and lithium bistrifluoromethanesulfonimide to obtain a PEDOT:PSS / EG / LiTFSI solution, which comprises the following steps:

[0095] 1) Prepare PEDOT:PSS / 5wt%EG / 30wt%LiTFSI solution

[0096] The addition amount of LiTFSI was changed to account for 30wt% of the total system, and other steps were the same as those in Example 1.

[0097] 2) Viscosity test

[0098] The viscosity of the PEDOT:PSS / 5wt%EG / 30wt%LiTFSI solution was measured by a digital viscometer, and the viscosity was 18.7cP.

[0099] 3) Surface tension test

[0100] The surface tension of the PEDOT:PSS / 5wt%EG / 30wt%LiTFSI solution was tested with a surface tensiometer, and the surface tension was 34.2 mN / m.

[0101] 4) Preparation of flexible self-supporting PEDOT:PSS / 5wt%EG / 30wt%LiTFSI films

[0102] The preparation process is the same as in Example 1.

[0103] 5) Conductivity test

[0104] The conductivity of PEDOT:PSS / 5w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com