OCA adhesive tape applied to folding mobile phone

A technology for folding mobile phones and tapes, applied in the field of flexible materials, can solve problems such as easy fracture or delamination, and large modulus, and achieve the effect of reducing the risk of fracture or delamination, low modulus, and improving crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

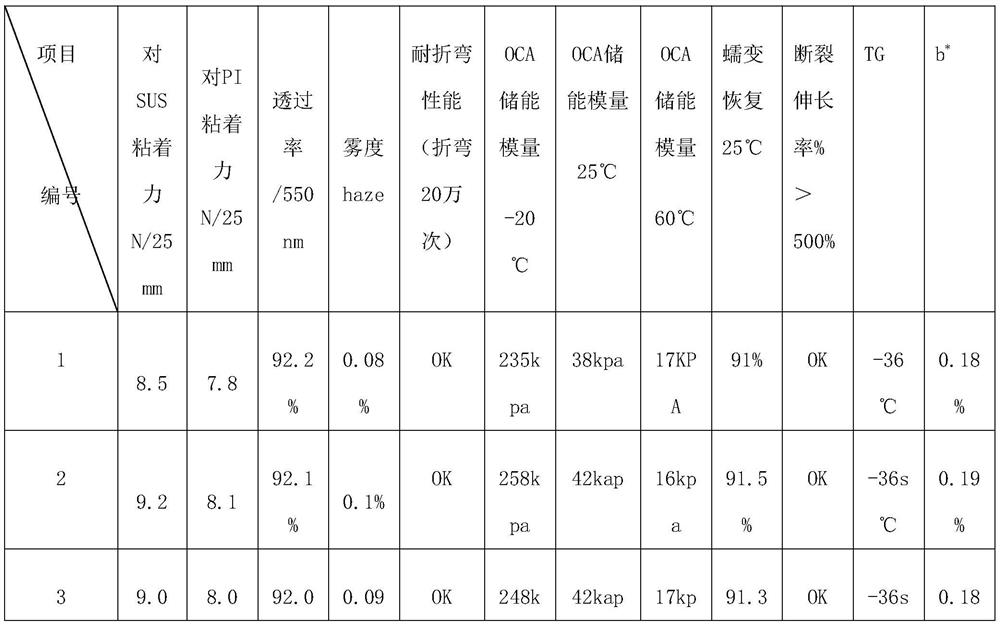

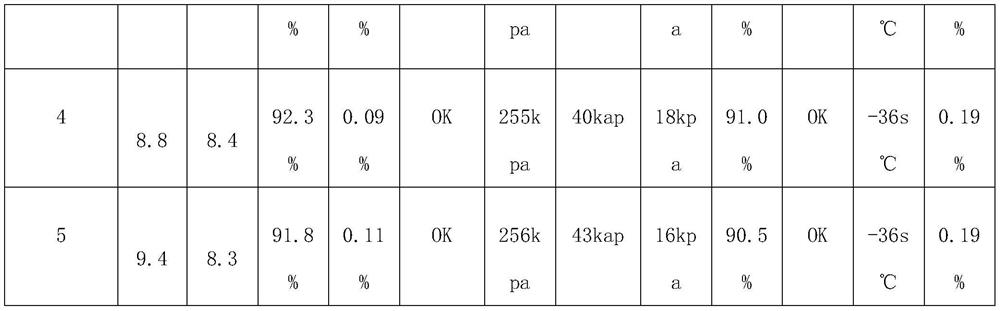

Examples

Embodiment 1

[0019] Synthetic OCA glue

[0020] 20wt% monomer (mass ratio 1:2:3:4 butyl acrylate, ethyl acrylate, 2-ethylhexyl methacrylate, lauryl acrylate), 0.1wt% initiator benzoyl peroxide , and the remaining amount of toluene was added to the reaction kettle, and polymerized at 70° C. for 6 hours to obtain an acrylate-based copolymer. Based on this acrylate copolymer, it is measured as 25wt% of the raw material of the OCA adhesive layer, and then 55wt% of diluent solvent ethyl acetate and the balance of toluene are added to adjust to a reasonable viscosity of 5000-6000cps, that is, OCA glue is obtained to prepare OCA adhesive tape

[0021] Select a 75μm release layer with a suitable release force (15-100g), apply the OCA glue (dry glue thickness) prepared by 75μm through a slit or a doctor blade, and then heat it in an oven. The 50μm plane release film with the force (3-50g) produces the finished OCA tape without substrate.

Embodiment 2

[0023] Synthetic OCA glue

[0024] 30wt% monomer (mass ratio 1:1:1 of 2-ethylhexyl methacrylate, lauryl acrylate, methacrylic acid), 1t% initiator benzoyl peroxide, and the balance of toluene were added to the reaction The kettle was polymerized at 72°C for 6 hours to obtain an acrylate-based copolymer. Based on this acrylate copolymer, it is measured to account for 35wt% of the raw material of the OCA adhesive layer, then add diluting solvent 30-55wt% ethyl acetate and the balance of toluene, adjust to a reasonable viscosity of 5000-6000cps, that is, obtain OCA glue

[0025] Preparing OCA Tape

[0026] Select a 100μm release layer with a suitable release force (15-100g), apply it through a slit or a doctor blade, and directly apply the OCA glue (dry glue thickness) prepared by 65μm. The 55μm plane release film with the force (3-50g) produces the finished OCA tape without substrate.

Embodiment 3

[0028] Synthetic OCA glue

[0029] 40wt% of monomer 2-ethylhexyl methacrylate, 2wt% of initiator dicumyl peroxide, and balance of toluene were added to the reaction kettle, and polymerized at 74° C. for 6 hours to obtain an acrylate copolymer. Based on this acrylate copolymer, it is measured as 45wt% of the raw material of the OCA adhesive layer, and then 40wt% of diluent solvent ethyl acetate and the balance of toluene are added to adjust to a reasonable viscosity of 5000-6000cps, that is, OCA glue is obtained to prepare OCA adhesive tape

[0030] Select an 85m release layer with a suitable release force (15-100g), apply it through a slit or a scraper, and directly apply the OCA glue (dry glue thickness) prepared by 33μm. A 65μm flat release film with a force (3-50g) is used to produce a finished OCA tape without a substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com